Steel strand mechanical testing device in ultra-low-temperature environment and testing method thereof

A technology of mechanical testing and steel strands, applied in the direction of measuring devices, scientific instruments, instruments, etc., to achieve the effects of uniform temperature distribution, high strength, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

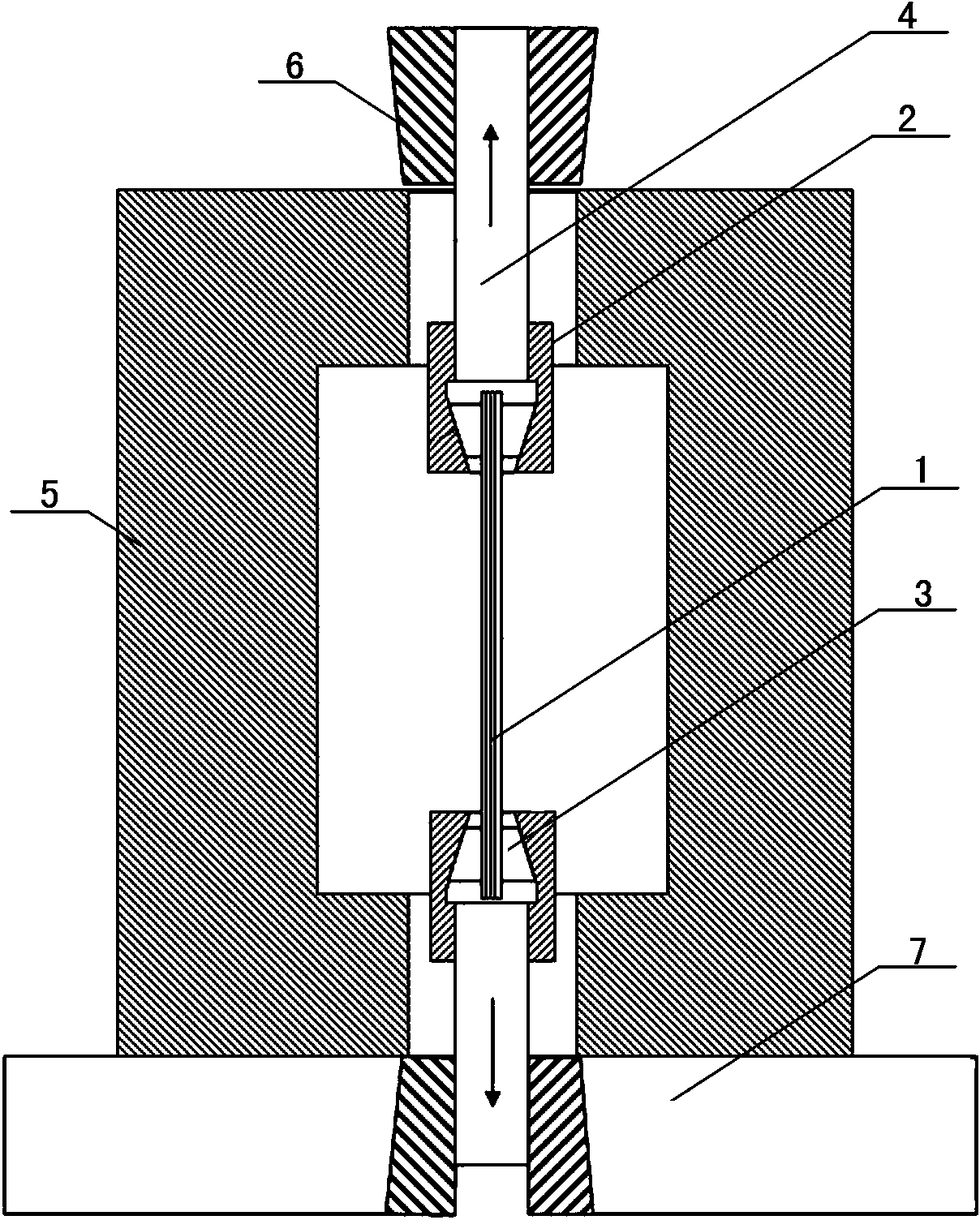

[0036] Examples see figure 1 As shown, the steel strand mechanical testing device under this ultra-low temperature environment includes a universal testing machine 7 and a low-temperature box 5 placed between the upper and lower jaws of the universal testing machine 7, and is characterized in that: the upper and lower sides of the low-temperature box 5 are respectively There is a through hole 5.14 corresponding to each other, which is used to connect the connecting assembly of the steel strand to be tested. Self-locking collet 3 is made up of, and one end of described dowel bar 4 passes through the through hole 5.14 of cryogenic box 5, is fixed by the jaw 6 of universal testing machine, and the other end is connected with connecting self-locking part 2, and described connection is self-locking. A self-locking collet 3 is built in the lock piece 2, and the self-locking collet 3 is clamped at the end of the steel strand 1 to be tested.

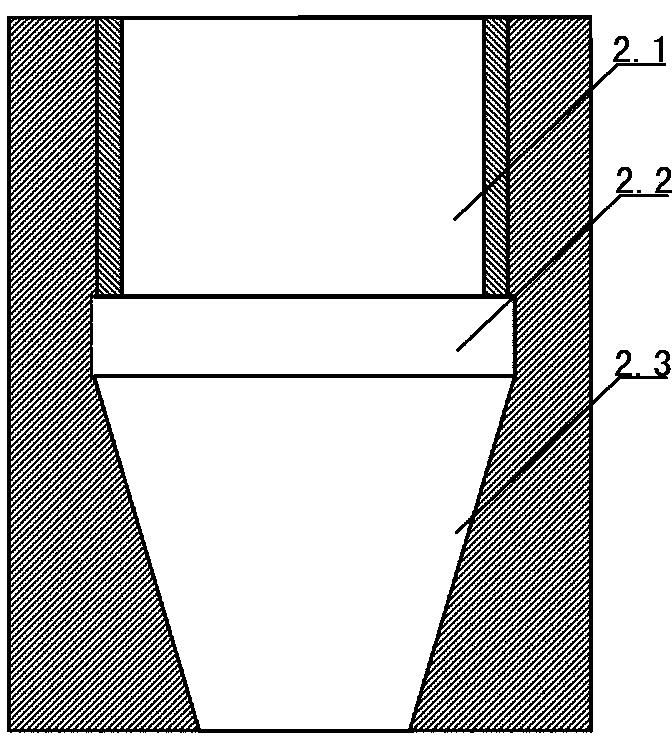

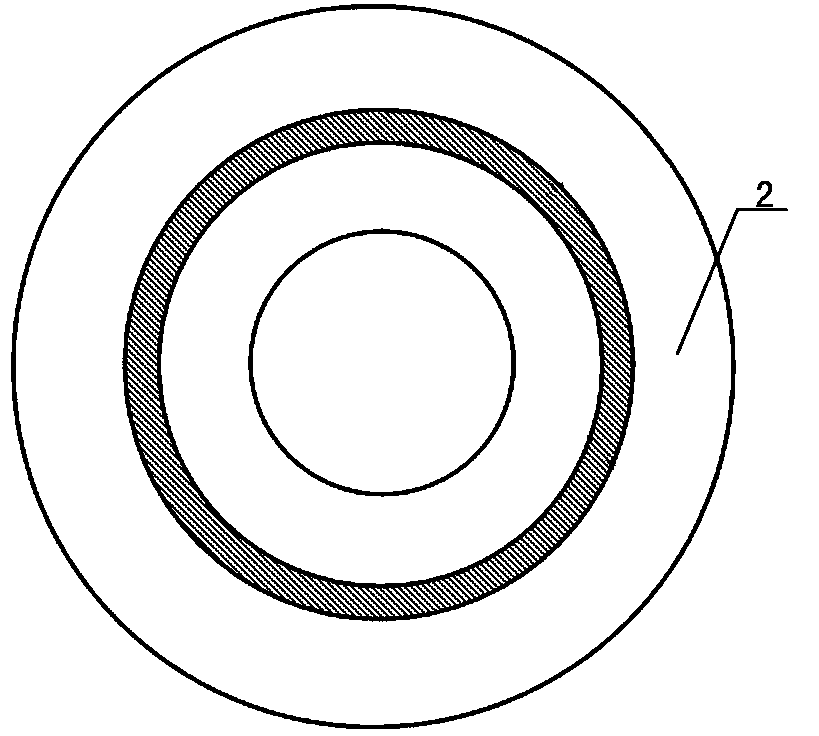

[0037] see figure 2 , image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com