Three/four-point bending performance test general clamp for material

A four-point bending and fixture technology, applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve the problems of inability to digitally display span, inability to realize variable speed adjustment, low test efficiency, etc., to avoid adverse effects and improve test efficiency. , the effect of quick placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to solve the above existing technical problems, the present invention is realized through the following technical solutions.

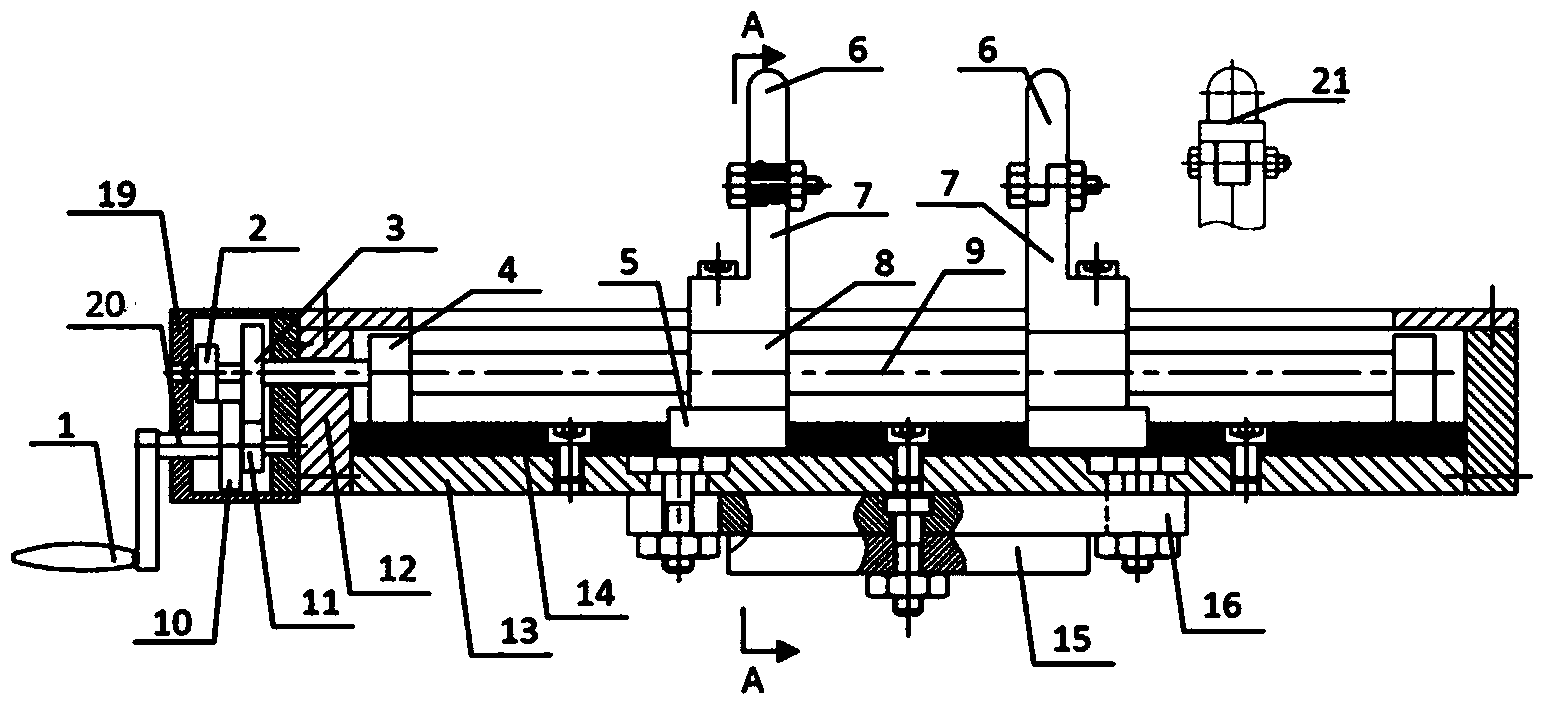

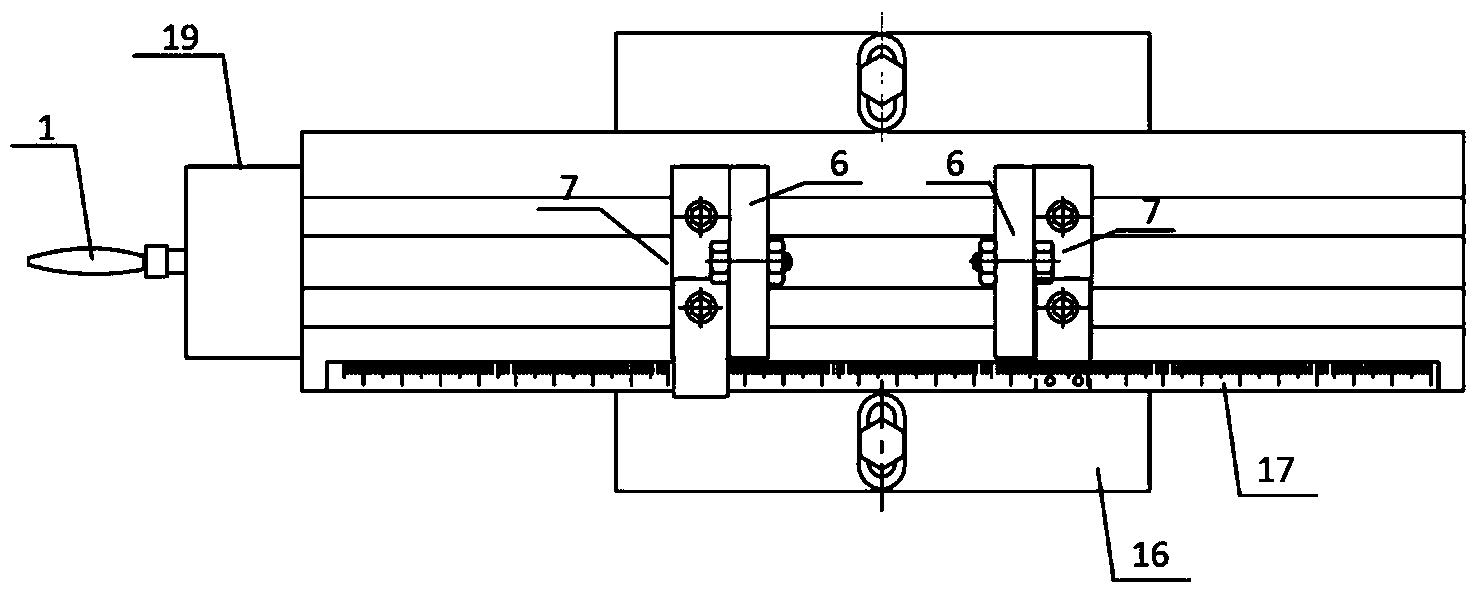

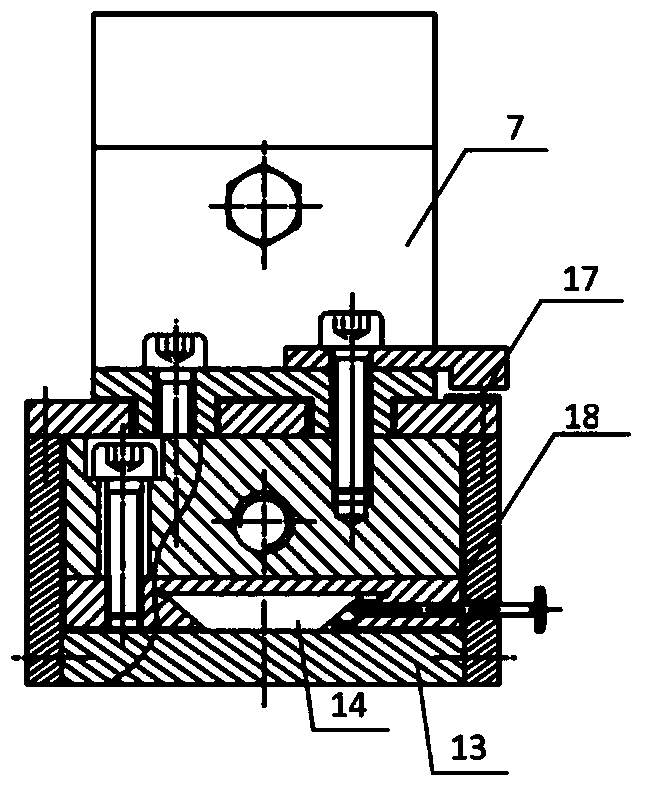

[0022] A universal jig for three- and four-point bending performance testing of materials is composed of an upper jig and a lower jig, and the upper jig and the lower jig have the same structure. The upper fixture includes: an adjustment platform, a span adjustment device, a span measurement device, and a combined pressure head, and the lower fixture includes: an adjustment platform, a span adjustment device, a span measurement device, and a combined support.

[0023] The span adjustment device includes a handle 1, a gear 2, a gear 3, a gear 10, a gear 11, a screw bracket 4, a sliding block 5, a screw nut 8, a screw 9, a baffle plate 12, a guide rail 14, a gear box 19, a lock Tighten the bolt 18 and the handle shaft 20; the adjustment platform includes the bottom plate 13, the front and rear adjustment plates 15 and the left and right a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com