Operation instrument for optical tweezers

A technique for manipulators and optical tweezers, which is applied in the field of optical tweezers manipulators, and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The optical tweezers technology using orthogonally deflected double optical wedges to precisely control particles will be further described in detail below with reference to the accompanying drawings, but the protection scope of the patent of the present invention is not limited thereto.

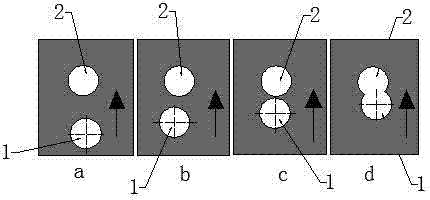

[0040] see figure 1 , the particle with a cross is the target particle 1 captured by the optical tweezers, and the target particle 1 moves gradually towards the stationary particle 2 under the action of the optical tweezers until fusion .

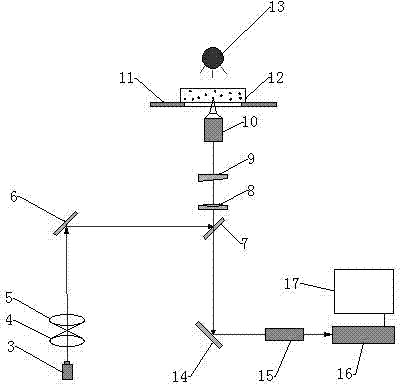

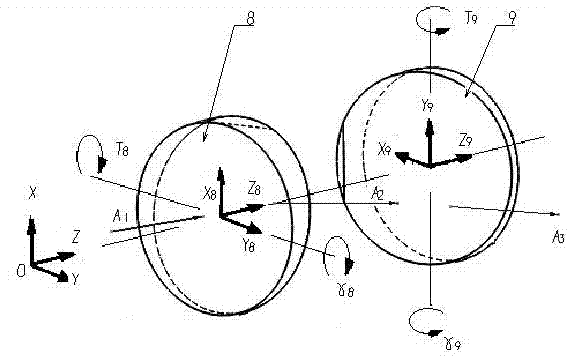

[0041] see figure 2 , the present invention provides a new technology for precise tracking and control of particle movement using a deflection double optical wedge, the technology includes:

[0042] Laser source 3, according to the principle of optical tweezers, the formation of light trap needs the light source of specific form, among the present invention, laser source 3 preferred Nd: the laser source of YAG 1064nm; The first convex lens 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com