Freezing station liquid ammonia automatic control system

A technology of automatic control system and freezing station, applied in control/regulation system, liquid level control, non-electric variable control and other directions, can solve the problems of hidden danger of liquid ammonia separator, inconvenient equipment maintenance, untimely monitoring, etc. Daily operating costs, improving equipment utilization, and ensuring the effect of freezing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

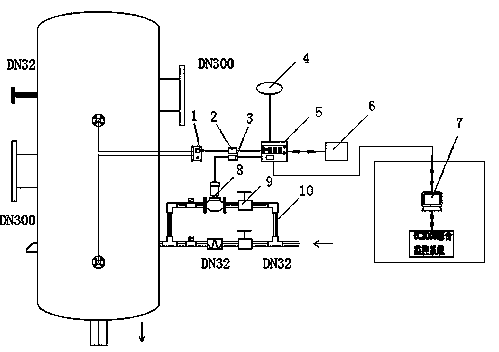

[0010] Such as figure 1 As shown, a liquid ammonia automatic control system of a freezing station has a liquid level sensor 1 for collecting the height of the ammonia liquid level in the liquid ammonia separator, and is connected with the liquid level sensor 1 to convert the liquid level analog signal collected by the liquid level sensor into A / D conversion module 2 for digital signals, PLC 5 connected to A / D conversion module 2, D / A conversion module 3 connected to PLC 5, electric valve 8 connected to D / A conversion module 3, connected to PLC5 A display operating device 6 for displaying ammonia liquid level data and operation, a host computer 7 connected with PLC5 for remote control, and an alarm device 4 connected with PLC; There is a pipeline 10 with a valve 9, the electric valve 8 is installed on the pipeline 10, and a manual switch is connected between the liquid level sensor 1 and the A / D conversion module 2.

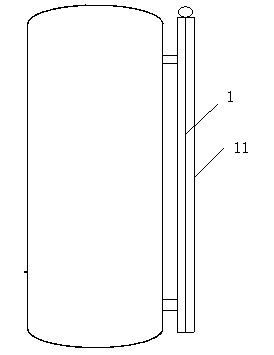

[0011] Such as figure 2 As shown, the liquid level sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com