On-line monitoring and controlling system used for sodium hypochlorite production

A technology of sodium hypochlorite and control system, which is applied in control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc. It can solve the problem of low efficiency, inability to continuously detect and control the amount of chlorine flow and reaction termination point, and air intake It is difficult to grasp the quantity and intake time, etc., so as to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

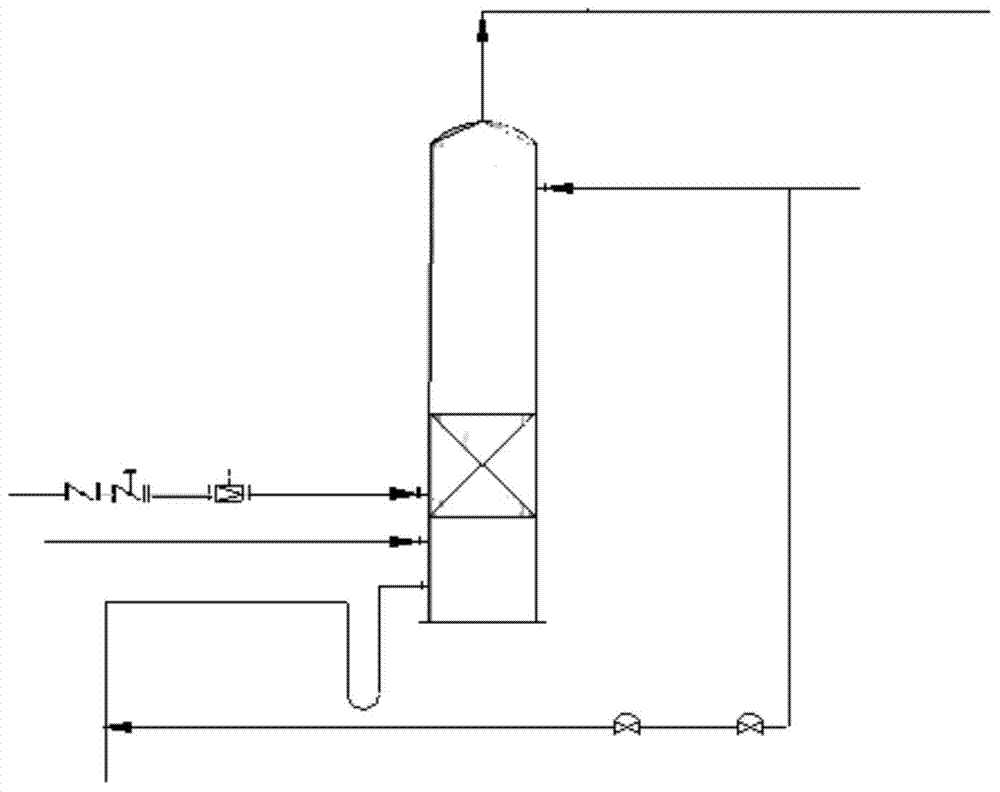

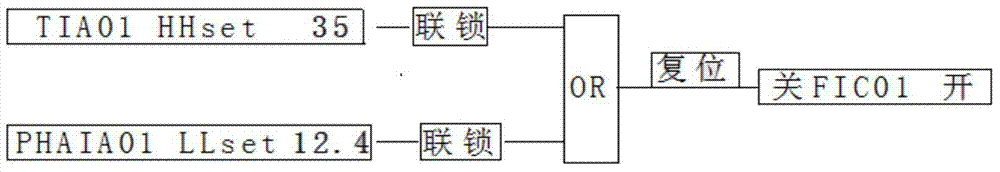

[0015] In the production process of sodium hypochlorite, as the reaction proceeds, the change of the over-alkaline content of the reaction solution will cause the change of the pH value of the reaction solution, so the information of the over-alkaline content can be obtained from the pH value; at the same time, as the reaction proceeds If the real-time intake air volume is too large, the violent reaction will generate a large amount of heat, which will cause the temperature of the reaction solution to exceed the control index and promote the decomposition of the generated sodium hypochlorite. Along with the carrying out of reaction, can not stop air intake in time when reaching the termination point of reaction and can cause the over-alkaline amount in the reaction solution to reduce, and sodium hypochlorite solution self-decomposes and impels decomposition to aggravate under the situation that there is no certain over-alkali amount protection. Based on the above-mentioned prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com