Optimal scaling modeling method of aeroelasticity wind-tunnel model of composite material wing

A technology of aeroelasticity and modeling method, which is applied in the field of structure and test of aeronautical vehicles, and can solve problems such as difficulty in establishing scale models under similar conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

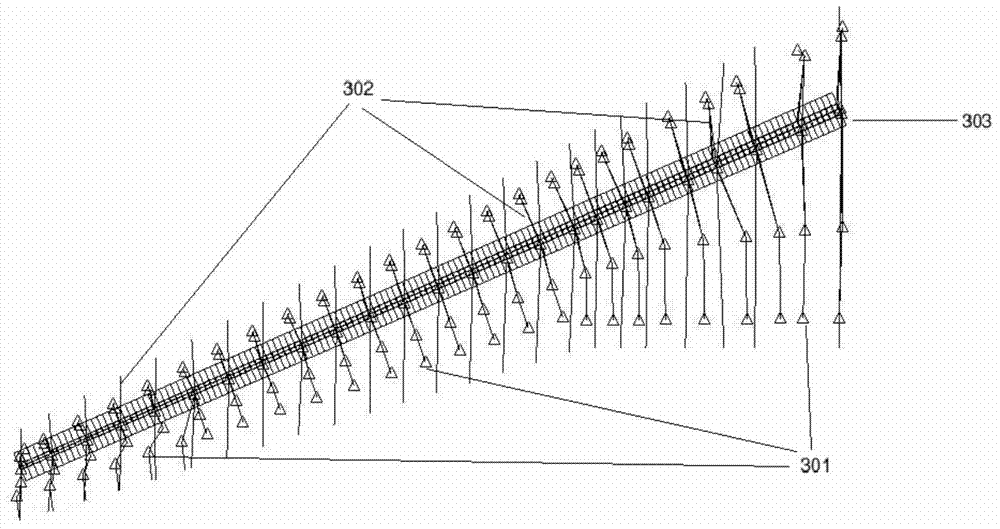

[0016] The wind tunnel test is carried out according to the principle of relativity and similarity.

[0017] The basis of the aeroelastic model test is the similarity law of aeroelastic scaling. For different aeroelastic phenomena, the corresponding similarity law can be obtained through the similarity transformation of the motion equation. The speed and dither frequency can then be determined. There are many similar proportions k between the model and the real object. For the aeroelastic model, the low-speed test takes k l ,k V ,k ρ For the basic similarity ratio, take k for the high-speed test l ,k q ,k ρ are basically similar proportions, where l, V, q, ρ represent length, velocity, velocity pressure and density respectively.

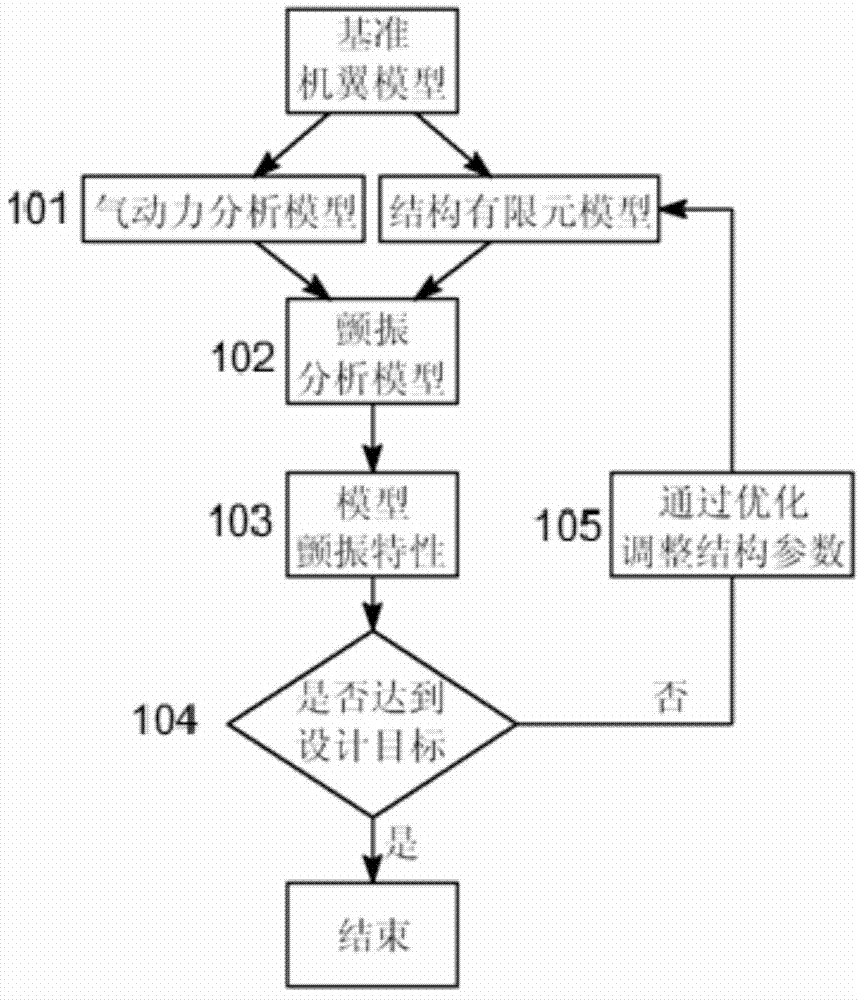

[0018] The aeroelastic scaling modeling is to reconstruct the aeroelastic characteristics of the original structure on the scaling model based on the similarity criterion. Since the aerodynamic shape remains similar, the problem is viewed as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com