Thermal production well casing tubular column total strain calculating method

A calculation method and casing string technology, applied in the field of drilling and oil production, can solve problems such as the inability to meet the needs of oilfield field operations, and achieve the effect of ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

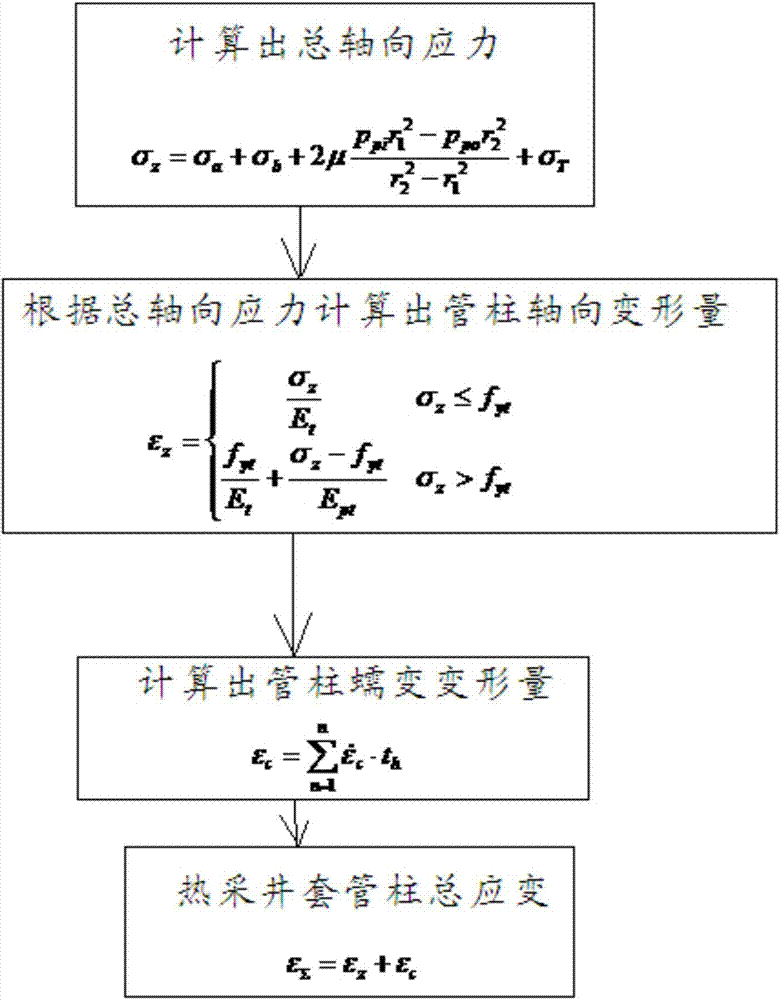

[0011] see figure 1 , a method for calculating the total strain of a casing string in a thermal recovery well provided in an embodiment of the present invention includes the following steps:

[0012] Step 1, calculate the total axial stress σ z . by formula The total axial stress is obtained; among them, the casing material Poisson's ratio μ, the casing inner diameter r 1 , casing outer diameter r 2 , internal pressure p pi , external pressure p po , the axial stress σ generated by the pipe’s own weight a , the bending stress σ caused by the dogleg degree b , the thermal stress σ generated by the temperature change T .

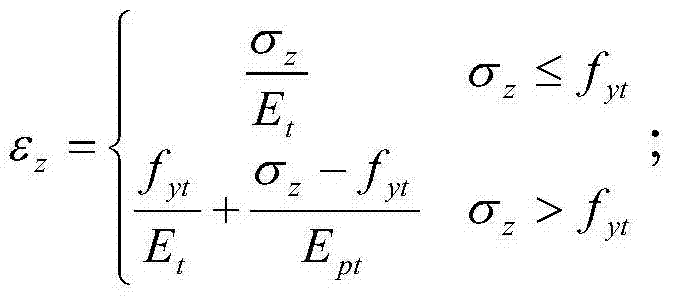

[0013] Step 2, calculate the axial deformation of the pipe string ε according to the total axial stress z . The formula for calculating the axial deformation of the pipe string is ϵ z = σ z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com