Novel box-type transformer substation

A box-type substation, a new type of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

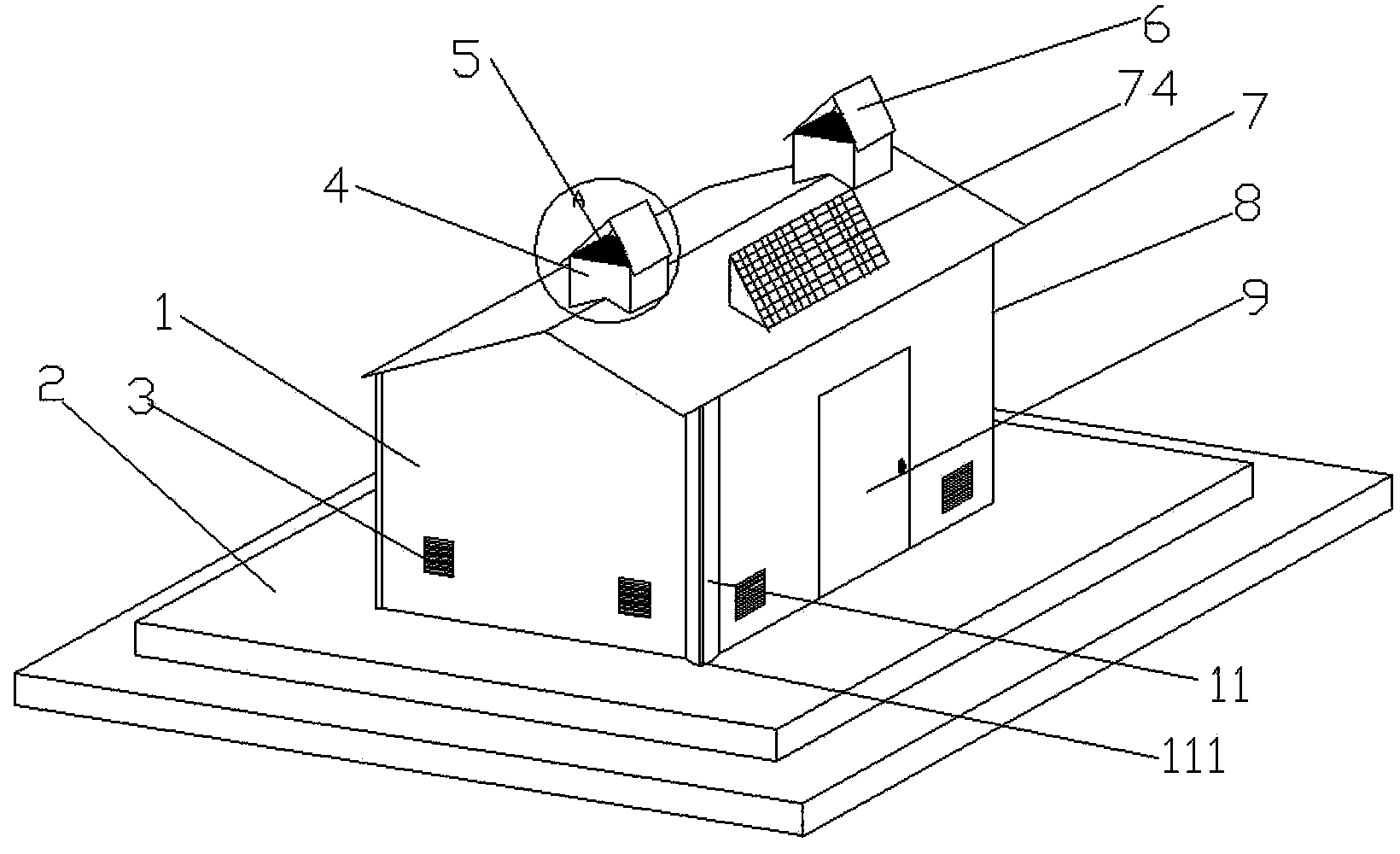

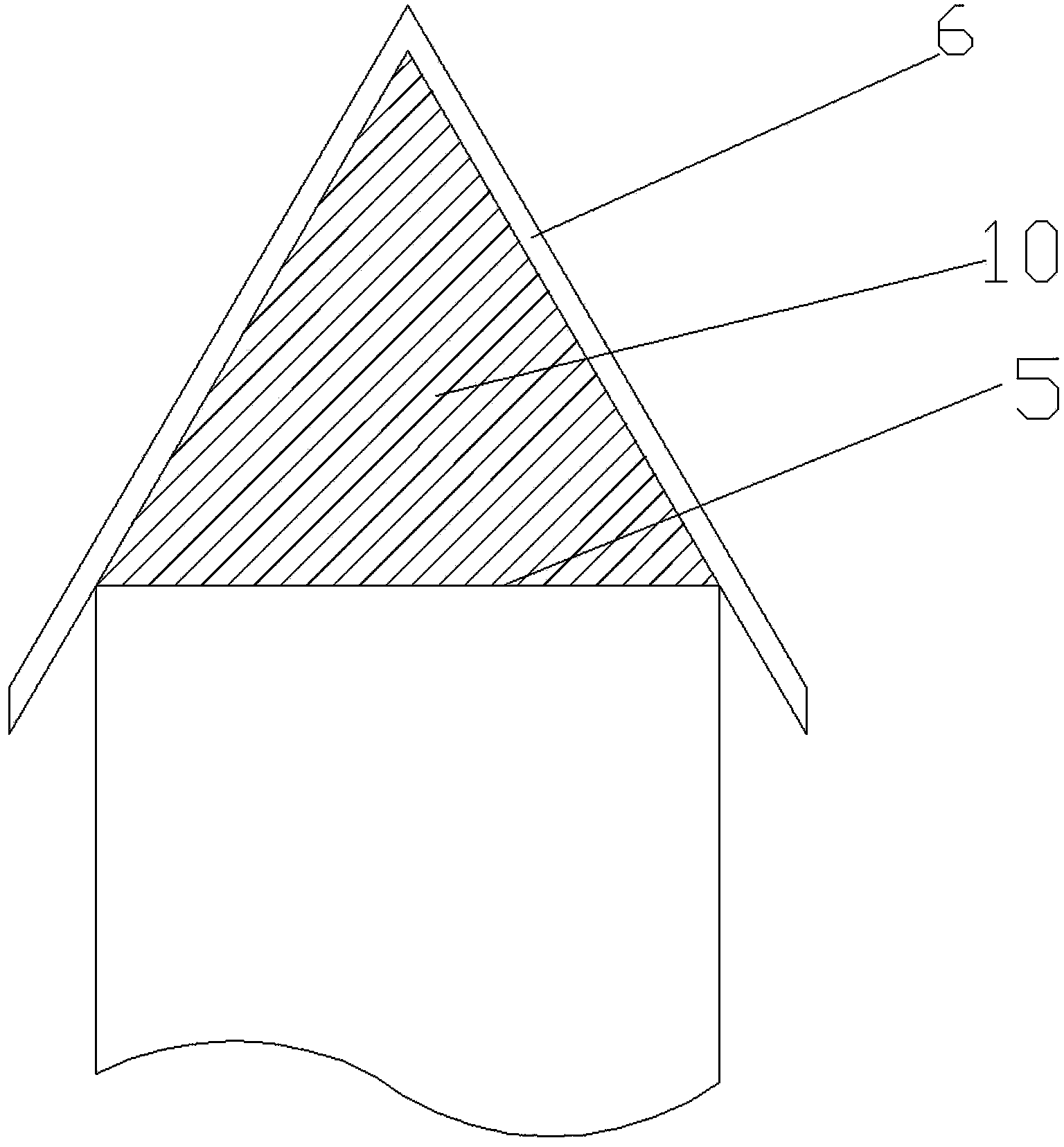

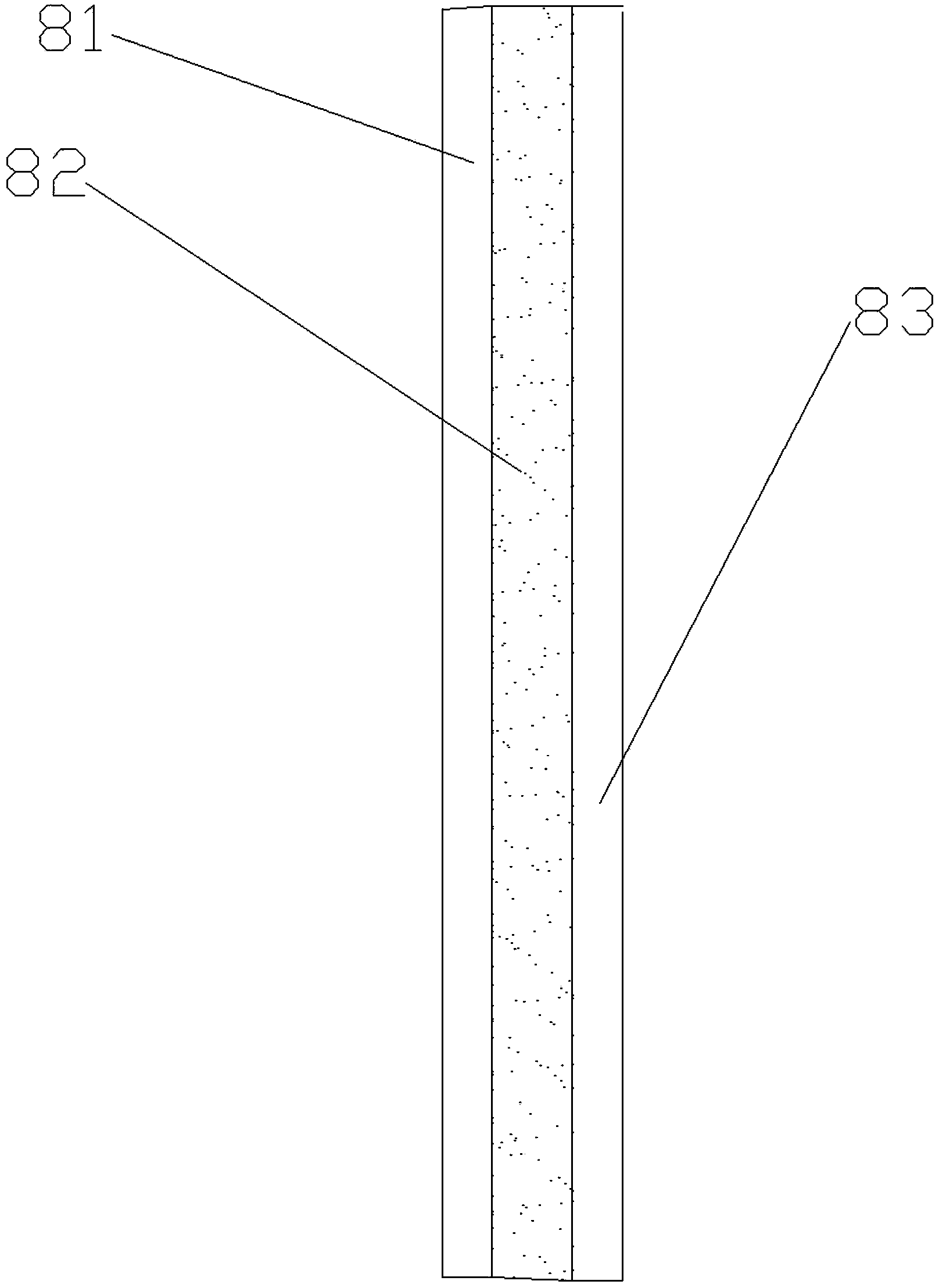

[0033] As a preferred embodiment of the present invention, the present invention includes a box body 1 and a base 2, and the box body 1 is composed of a column 11 around, a wall plate 8, a door 9 and a slope-shaped cover plate 7 at the top, and is characterized in that : the top of the slope-shaped cover plate 7 is provided with at least one column vent 4, the column vent 4 protrudes from the slope-shaped cover plate 7, and a layer of gauze 5 is arranged on the column vent 4, Described column air vent 4 is also provided with rain shielding plate 6, and stainless steel wire mesh 10 is housed between described rain shielding plate 6, and described stainless steel wire mesh 10 is fixed on rain shielding plate 6 both sides by screw. The wall board 8 is composed of an outer wall board 83, a vacuum board 82 and an inner wall board 81, the vacuum board 82 is bonded between the outer wall board 83 and the inner wall board 81, and a solar controller is also installed on the inner wall b...

Embodiment 2

[0039] As another preferred embodiment of the present invention, the present invention includes a box body 1 and a base 2. The box body 1 is composed of columns 11 around, wall panels 8, doors 9 and slope-shaped cover plates 7 at the top. In that: the top of the slope-shaped cover plate 7 is provided with at least one column vent 4, the column vent 4 protrudes from the slope-shaped cover plate 7, and a layer of gauze 5 is arranged on the column vent 4 , said column air vent 4 is also provided with a rain shield 6, stainless steel wire mesh 10 is housed between said rain shield 6, and said stainless steel wire mesh 10 is fixed on both sides of the rain shield 6 by screws. The wall board 8 is composed of an outer wall board 83, a vacuum board 82 and an inner wall board 81, the vacuum board 82 is bonded between the outer wall board 83 and the inner wall board 81, and a solar controller is also installed on the inner wall board 81 84 and accumulator 85; described slope cover plate...

Embodiment 3

[0046] As another preferred embodiment of the present invention, the present invention includes a box body 1 and a base 2. The box body 1 is composed of columns 11 around, wall panels 8, doors 9 and slope-shaped cover plates 7 at the top. In that: the top of the slope-shaped cover plate 7 is provided with at least one column vent 4, the column vent 4 protrudes from the slope-shaped cover plate 7, and a layer of gauze 5 is arranged on the column vent 4 , said column air vent 4 is also provided with a rain shield 6, stainless steel wire mesh 10 is housed between said rain shield 6, and said stainless steel wire mesh 10 is fixed on both sides of the rain shield 6 by screws. The wall board 8 is composed of an outer wall board 83, a vacuum board 82 and an inner wall board 81, the vacuum board 82 is bonded between the outer wall board 83 and the inner wall board 81, and a solar controller is also installed on the inner wall board 81 84 and accumulator 85; described slope cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com