Modular multilayer disc type motor based on effective magnetic domain technology

A disc motor, modular technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of disc motor overtaking, use no one raised, etc., to achieve the effect of increasing the magnetic flux density, the rate of change, and the output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

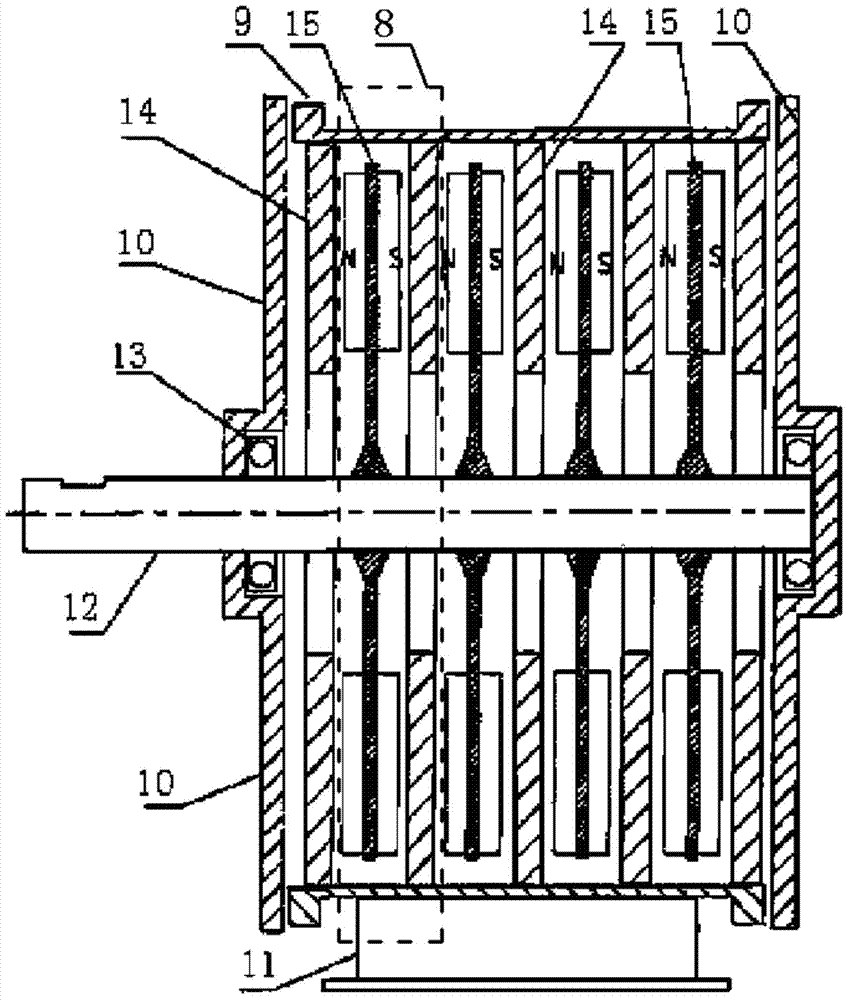

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 , 2 As shown in , the modular multilayer disc motor based on effective magnetic field technology includes: a housing 9, a base 11, an end cover 10, a rotating shaft 12, a bearing 13, a rotor 15, and a stator winding 14. The end cover 10 It is connected and fixed with the casing 9, and the rotating shaft 12 and the end cover 10 are assembled through the bearing 13; the rotor 15 is disc-shaped and is connected and fixed with the rotating shaft 12, and the rotor is fixedly embedded with two parts exposed to the rotor disk surface. The permanent magnet on the side, the stator winding 14 on the end side is fixed with the end cover.

[0031] The multi-layer disc motor uses a rotor 15 and a stator winding 14 next to it as a kinetic energy conversion unit 8, and multiple kinetic energy conversion units are aligned and stacked in sequence in the axial direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com