Recycling process and equipment for glyphosate exhaust gas absorption liquid

A technology of tail gas absorption and glyphosate, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the amount of absorption liquid used, the cost of recovery, environmental protection problems, etc., so as to avoid mass production and improve absorption. Efficiency, achieve the effect of environmental protection recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

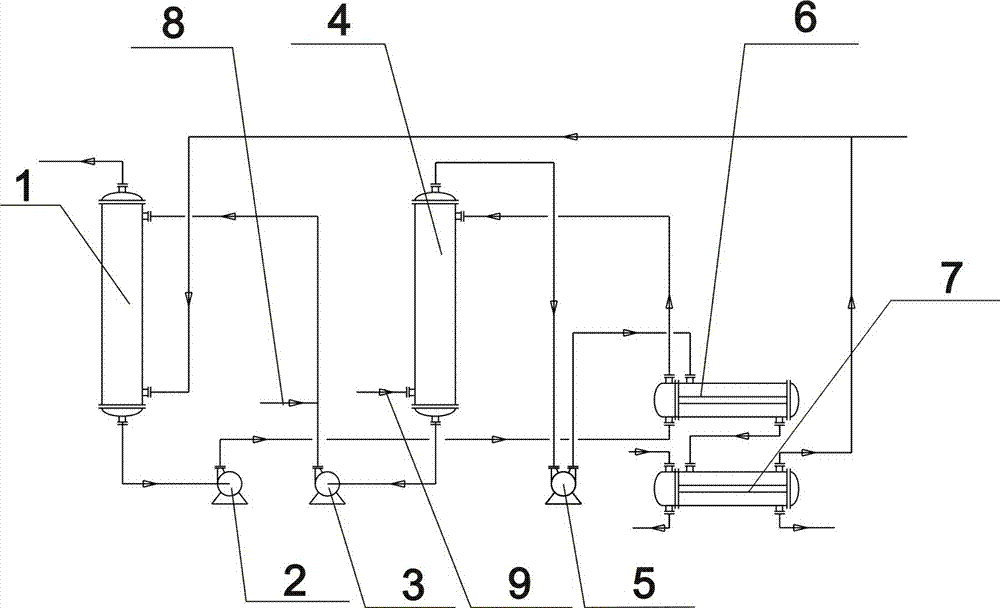

[0015] Lead the methyl chloride tail gas into the absorption tower 1, and the methylal aqueous solution with a mass concentration of 0.1% enters the upper part of the absorption tower and contacts the methyl chloride tail gas in the lower part of the absorption tower in countercurrent, and the flow rate of primary clean water replenishment is controlled to 40m 3 / h, the vacuum pump 5 is running, and the vacuum degree of the desorption tower 4 is stably controlled at 9.5KPa. The absorption liquid is pumped into the desorption tower 4 for circulation through the circulation pump 2. According to the content of the liquid methylal extracted from the bottom of the desorption tower 4, gradually increase the Pure methyl chloride and control the flow rate of pure methyl chloride to 100Kg / h, keep the content of methylal in the liquid extracted from the bottom of the desorption tower below 0.2%. The desorption liquid is pumped into the absorption tower 1 through the circulation pump 3 fo...

Embodiment 2

[0017] The 10% methylal dilute solution recovered by washing the exhaust gas of methyl chloride was mixed with 40 m 3 The flow rate of / h is passed in the desorption tower 4, continuously replenishes pure methyl chloride and controls the replenishment flow rate at 400Kg / h, starts the vacuum pump 5, controls the pressure of the desorption tower 4 at 5KPa, and the desorption tail gas enters the heat exchanger 6 successively after passing through the vacuum pump, and condenses 7. Control the return gas temperature of the condenser at -5°C and the condenser pressure at 120KPa (absolute pressure). The methylal and a small amount of water in the gas are condensed and separated to form a concentration of methylal with a mass concentration higher than 50%. The liquid enters the rectification tower for recycling, and the desorption liquid formed by the desorption tower with a mass concentration lower than 0.2% is supplemented to carry out washing and recovery of methyl chloride.

Embodiment 3

[0019] The methyl chloride tail gas produced by glyphosate enters the absorption tower, and the pure water enters the upper part of the absorption tower to contact the methyl chloride tail gas in the lower part of the absorption tower countercurrently. 3 / h, the amount of fresh water replenishment should ensure that the total circulation of the absorption tower is equal to the output of the absorption liquid in the absorption tower, and ensure that at least 75% of the methanol and methylal in the methyl chloride tail gas are washed down, and the methyl chloride gas after washing Entering the follow-up recovery process, the absorption liquid will contain methanol and methylal after one wash and be further recycled.

[0020] The absorption liquid after one wash in the above steps is pumped into the heat exchanger through the circulating pump, and after the absorption liquid is heated up to 28°C in the heat exchanger, it is sent to the desorption tower which is vacuumed and decomp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap