Micro-scale substance separating method and capillary column transverse eletrochromatography separating device

A chromatographic separation and capillary column technology, which is applied in the field of capillary column transverse electrochromatographic separation devices, can solve the problems of low separation degree of micro-scale substances, increase the contact probability of particles and column surface, etc., and achieve the effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

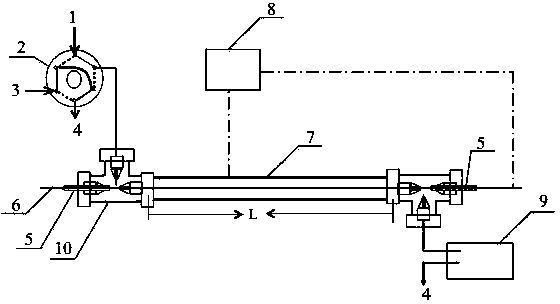

[0022] exist figure 1 Middle, 1. Carrier liquid, 2. Six-way injection valve, 3. Sample, 4. Waste liquid, 5. PEEK tube, 6. Conductive material—internal electrode, 7. Capillary—outer electrode, 8. Power supply, 9, Detector, 10, three-way valve.

[0023] refer to figure 1 , a capillary column transverse electrochromatographic separation device, comprising a pump providing a carrier liquid, a sampler, a detector, a power supply and one end connected to the sampler, and the other end connected to a separation column of the detector, wherein the separation column includes There are: a capillary 7, the capillary 7 is used as an external electrode; a conductive material 6, the conductive material 6 can be platinum wire, gold wire or silver wire, and the conductive material 6 is used as an internal electrode, passing through the capillary 7 in the axial direction , in order to ensure that the substances to be separated in the separation column are subjected to the same transvers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com