Kitchen waste disposer

A kitchen waste and processing machine technology, applied in the field of kitchen equipment, can solve the problems of waste of resources, breeding of mosquitoes and flies, and reduced processing efficiency, and achieve the effects of facilitating centralization, improving production efficiency, and improving the degree of integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

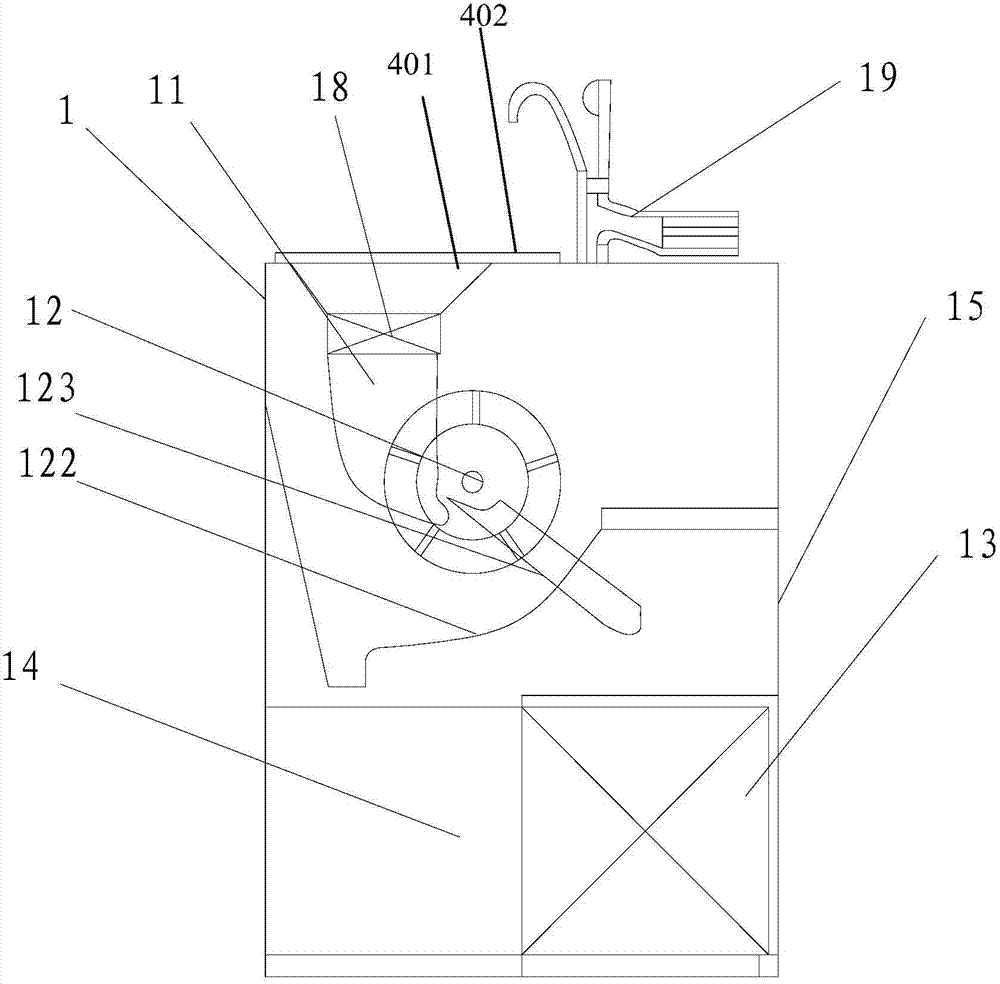

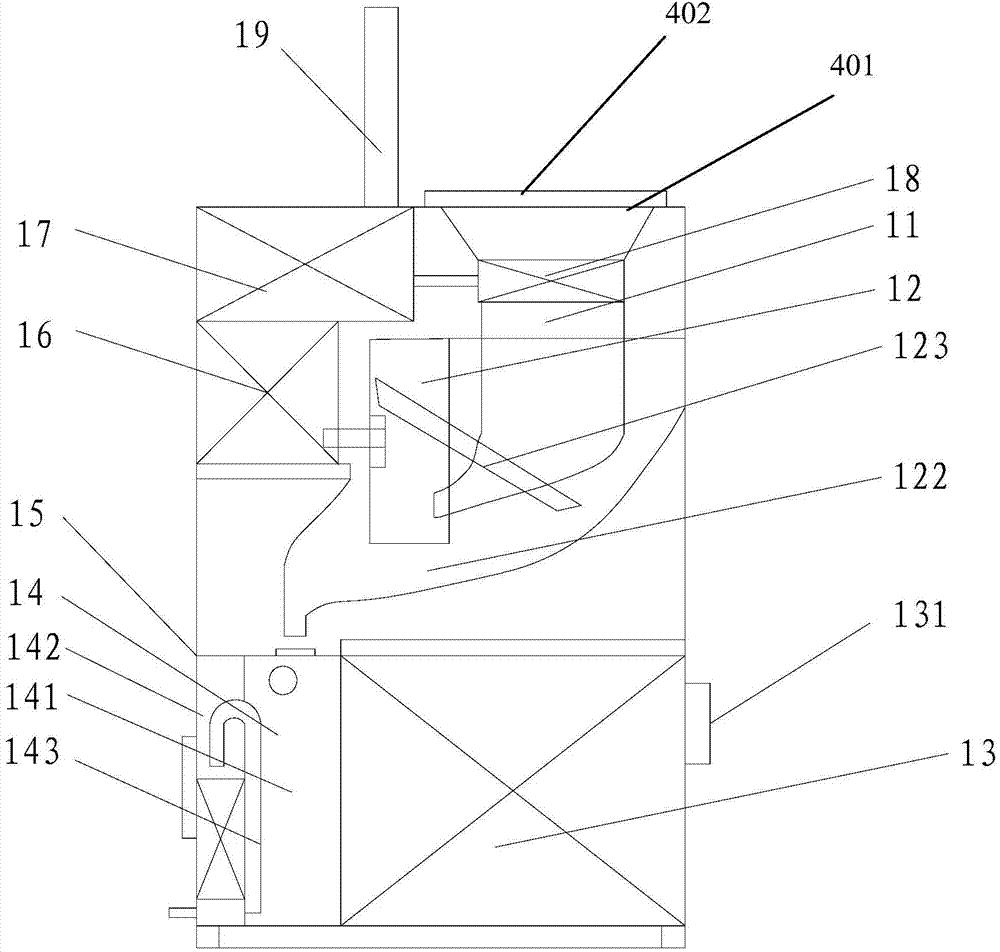

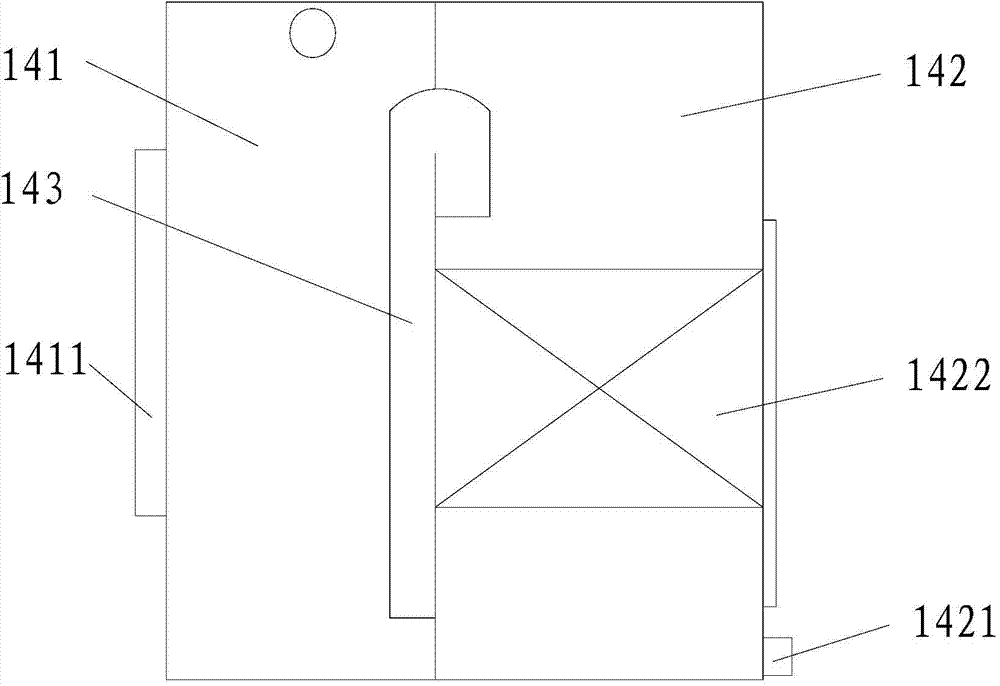

[0027] The invention provides a food waste processing machine, which includes a feeding channel 11 arranged in sequence, a separation unit 12 for sorting food waste into solid and liquid waste, and a solid waste collection unit for collecting solid waste and liquid waste respectively. Collection box 13 and liquid garbage collection box 14; feeding pipeline 11, separation unit 12, solid garbage collection box 13 and liquid garbage collection box 14 are all fixedly installed on the frame 15;

[0028] The feeding pipeline 11 includes an inlet pipeline 111, a transition pipeline 112 and an outlet pipeline 113 arranged in sequence; the transition pipeline 112 is provided with a plurality of leakage holes 1121 near the outlet pipeline 113;

[0029] The separation unit 12 includes a drum type feeder 121, a liquid garbage collection guide plate 122 and a solid waste collection guide plate 123; the drum type feeder 121 is a circular tank body, and a plurality of feeding plates 1211 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com