Drilling tool for forming R type center hole by one step

A technology for drilling tools and center holes, which is applied in the direction of center drills, drilling tool accessories, drilling/drilling equipment, etc., which can solve the difficulty in achieving the consistency of machining accuracy and roughness R-shaped center holes, which restricts the development of enterprises and users Technical requirements and other issues, to achieve the effect of promoting enterprise development, improving work efficiency, roughness and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

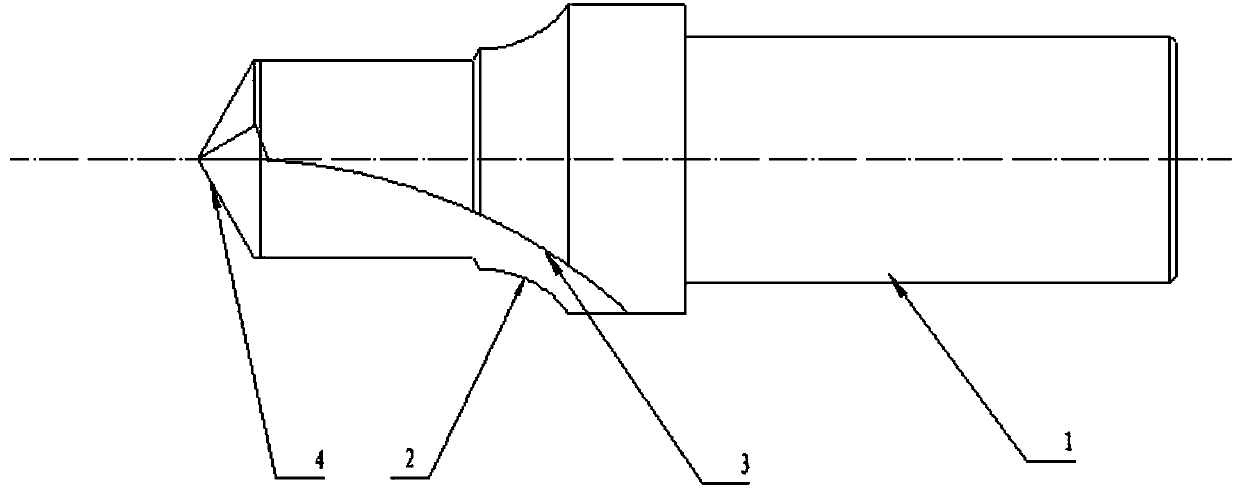

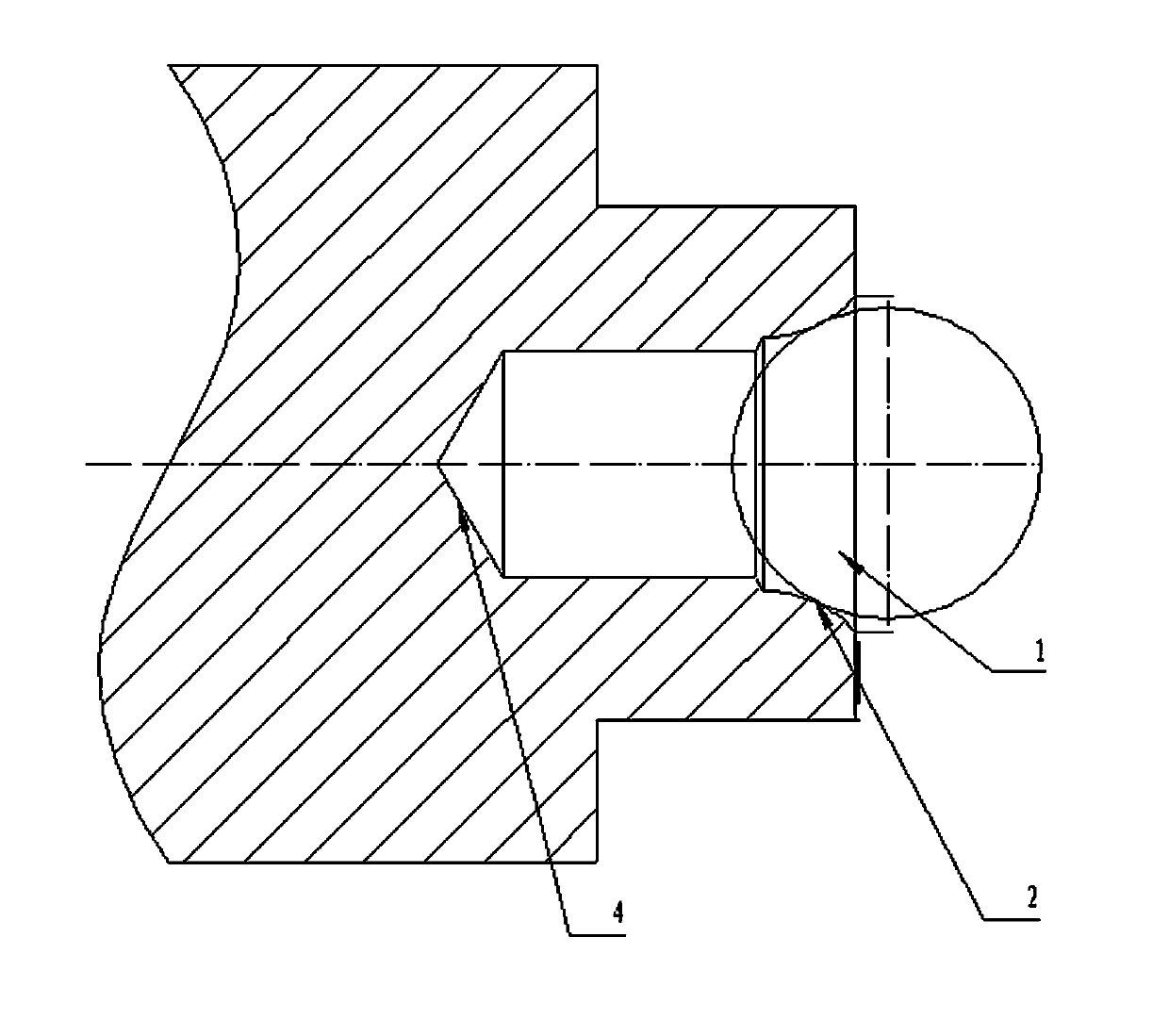

[0014] The drilling tool for one-time forming R-shaped central hole of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] Depend on figure 1 , figure 2 It can be seen that the drilling tool for one-time forming R-shaped central hole of the present invention includes a tool body 1, an R-shaped chip cutting edge 2 and a chip removal groove 3 are arranged in the middle of one end of the tool body 1, and the top of one end of the tool body 1 is arranged Chipping edges with top corners4.

[0016] The technology of this embodiment is mainly solved by the following technical solutions: by setting an R-shaped chip cutting edge 2 and a chip discharge groove 3 in the middle of one end of the tool body 1, the purpose of fast chip cutting, high machining dimensional accuracy, and one-time molding is realized. Thereby improving the performance of the product.

[0017] In this embodiment, the tool body 1 is made of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap