Fillet End Mills

A technology of end mills and rounded corners, which is applied in the direction of milling cutters, forming cutters, milling machine equipment, etc., can solve the problems of variable roughness of the processing surface, high cutting resistance, and inability to increase, etc., to achieve efficient lateral feed processing and rough surface The effect of smoothness and sharpness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

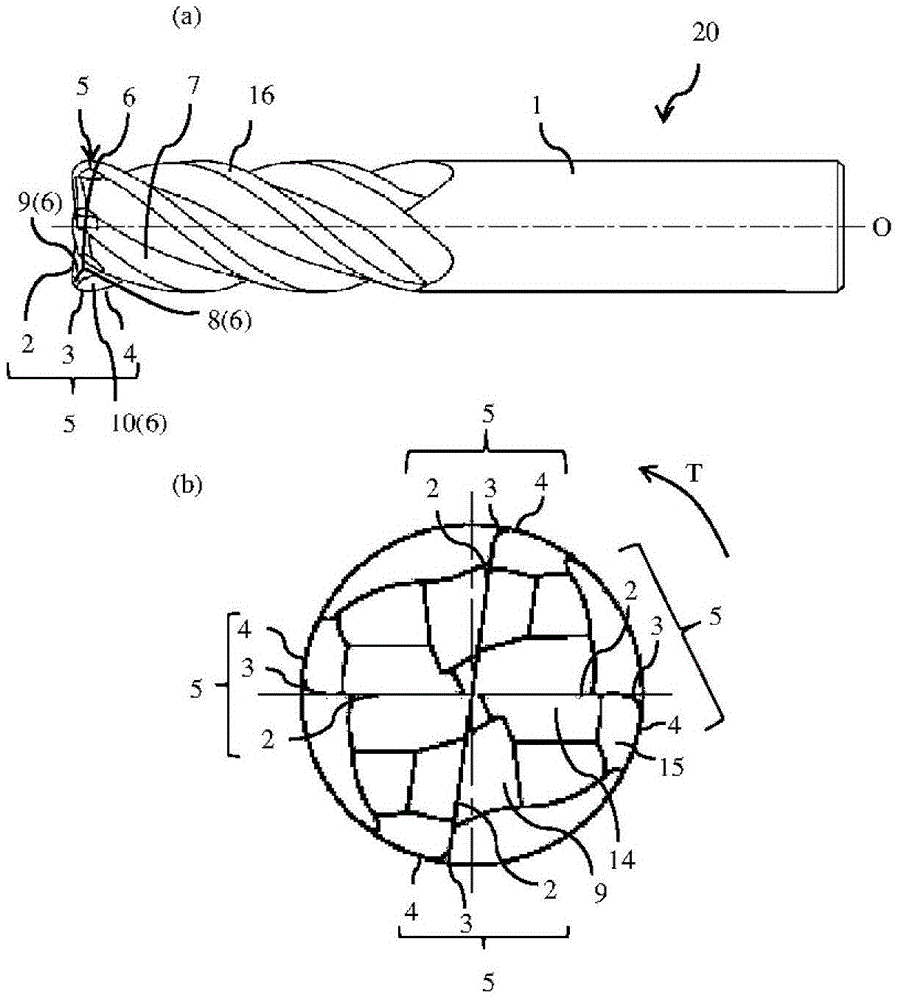

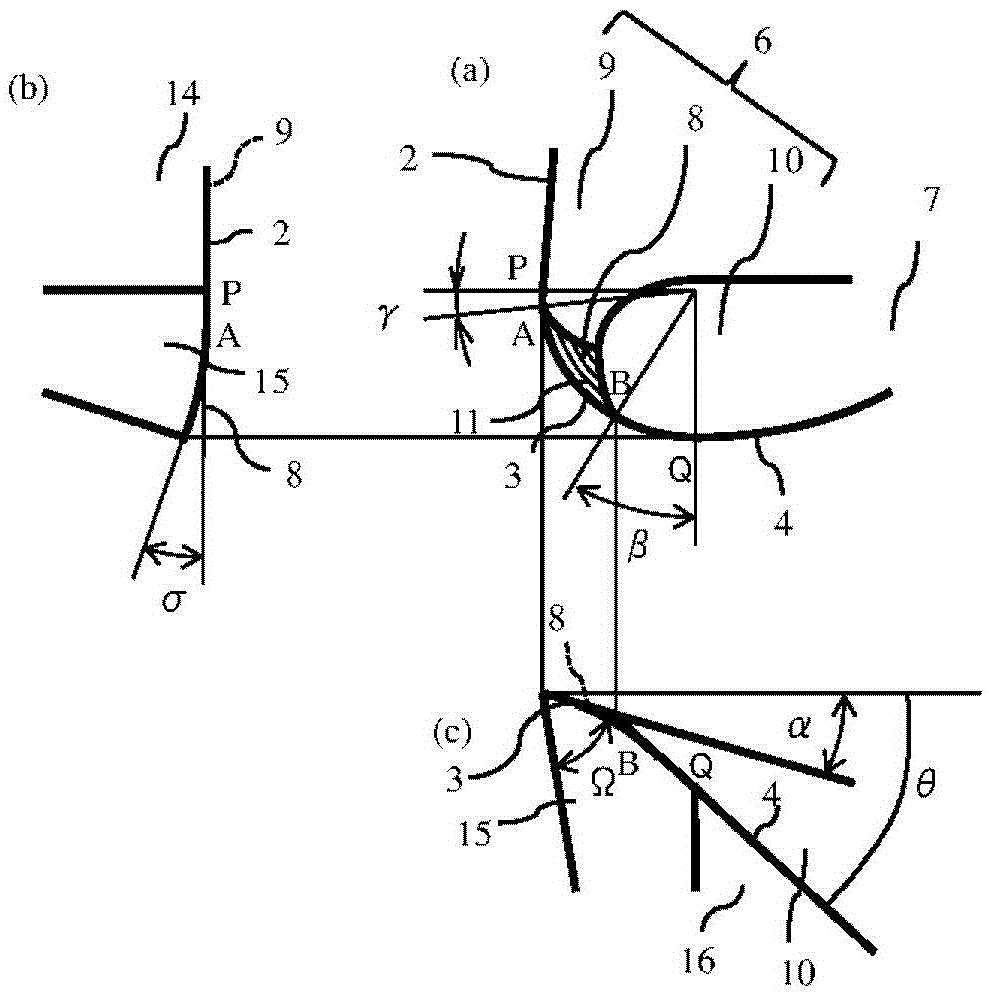

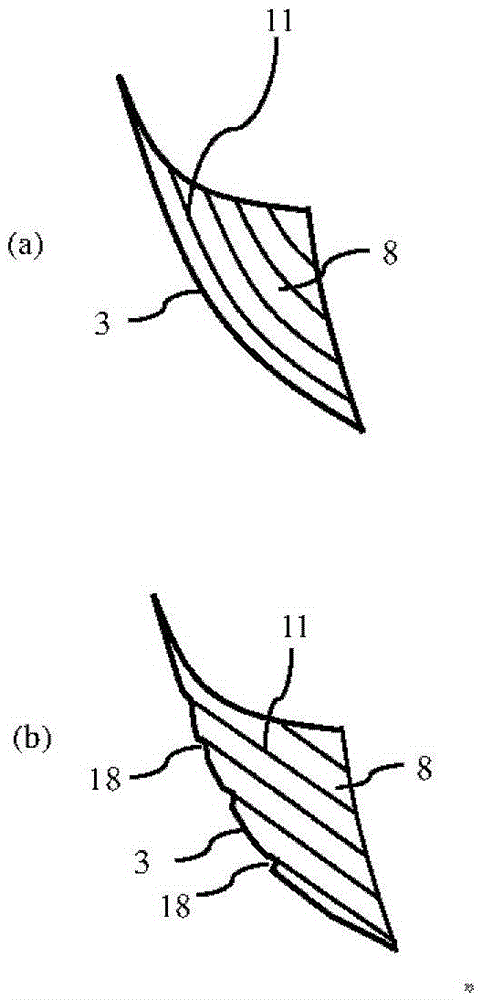

[0024] use figure 1 as well as figure 2 A preferred embodiment example of the radius end mill of the present invention will be described.

[0025] figure 1 , 2 The fillet end mill (hereinafter simply referred to as an end mill) 20 has a substantially cylindrical tool body 1 made of a hard material such as cemented carbide and having a rotational symmetry about a central axis O as a rotation axis. A bottom cutting edge 2 exists on the front end side of the tool body 1 that rotates around the center axis O. As shown in FIG. A peripheral cutting edge 4 exists on the outer periphery of the tool body 1 . A corner R cutting edge 3 connecting the bottom cutting edge 2 and the outer peripheral cutting edge 4 exists between them. Furthermore, the end mill 20 includes a plurality of cutting edges 5 in a series of bottom cutting edge 2 -corner R cutting edge 3 -outer peripheral cutting edge 4 on the front end side.

[0026] Further, a rake face 6 is provided continuously to the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com