cutting tool

A cutting tool and cutting edge technology, used in the manufacture of tools, workpieces, drilling tool accessories, etc., can solve the problems that the TiAlN film cannot sufficiently suppress the cutting edge chipping, the tool life cannot be stably extended, and wear, etc., to prevent chipping. , The effect of prolonging tool life and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

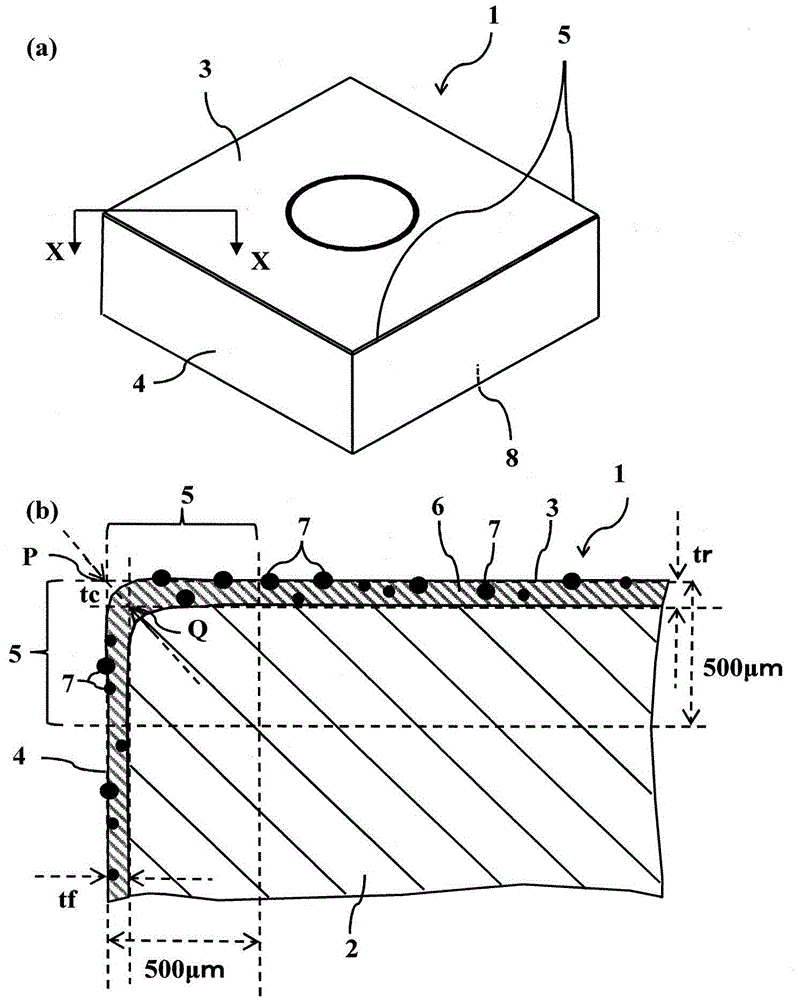

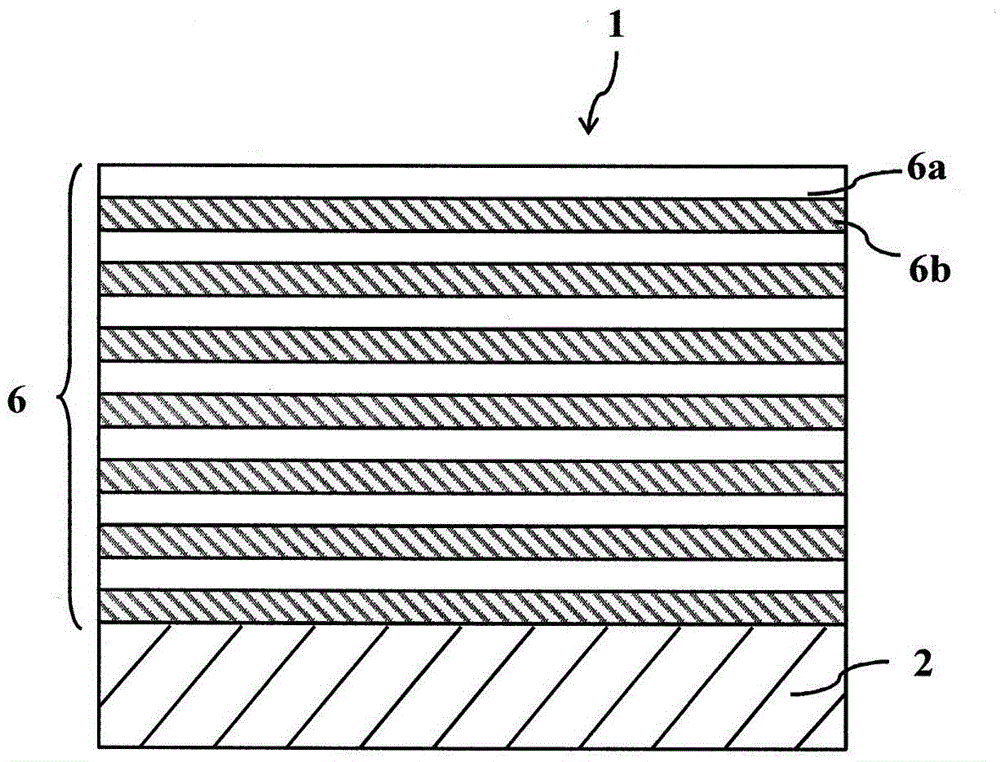

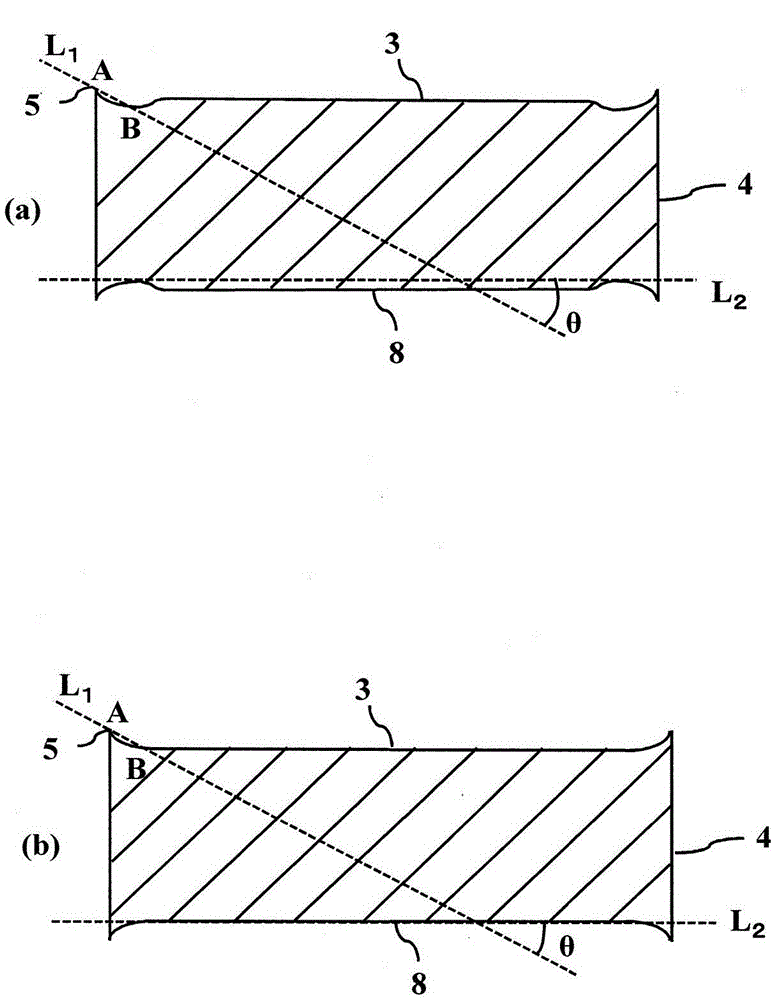

[0050]With tungsten carbide (WC) powder with an average particle size of 0.8 μm as the main component, metal cobalt (Co) powder with an average particle size of 1.2 μm is added at a ratio of 10 mass%, and cobalt (Co) powder with an average particle size of 1.0 μm is added at a ratio of 0.1 mass%. Vanadium carbide (VC) powder, chromium carbide (Cr 3 C 2 ) powder and mixed, and formed into a cutting tool BDMT11T308TR-JT shape (warped edge angle 16°, relief angle 18°) of Kyocera Cutting Tool by extrusion molding. The molded body was placed in a firing furnace, subjected to binder removal treatment, and fired at 1450° C. for 1 hour in a vacuum of 0.01 Pa to produce a cemented carbide. In addition, the rake face surface of each sample was ground by blasting, brushing, or the like. In addition, the produced cemented carbide is subjected to tip processing (honing) by brush grinding.

[0051] For the substrate produced in this way, the center magnets shown in Table 1 were placed on...

Embodiment 2

[0073] In the throwing insert of Sample No. 1 of Example 1, the shape of the throwing insert was changed to Kyocera cutting tools LOMU100408ER-SM (LOMU-SM), BDMT11T308ER-JS (BDMT-JS), SEKW120308TN ( SEKW) and SEKT1203 (SEKT) throw-away blade shapes, and others were prepared in the same manner as in Example 1, and a coating layer was formed. For the obtained sample, evaluation of the coating layer and cutting evaluation were performed in the same manner as in Example 1. The results are shown in Tables 5-8.

[0074] 【table 5】

[0075]

[0076] 【Table 6】

[0077]

[0078] 【Table 7】

[0079]

[0080] 【Table 8】

[0081]

[0082] According to the results shown in Tables 5 to 8, samples No. 10 and 11 with warpage edge angles of 43° and 25° have less welding on the workpiece and wear resistance than sample No. 1. It has good properties and can produce a smooth surface. In addition, samples No. 12 and No. 13, whose warpage edge angles were close to 0°, tended to have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com