Walking hydraulic system for scissor-type overhead working truck

A technology for aerial work vehicles and hydraulic systems, which is applied to fluid pressure actuating system components, fluid pressure actuating devices, lifting devices, etc., can solve the problems of low walking pressure and discontinuous vehicle walking, saving energy and reducing pressure. Loss, increase the effect of time of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

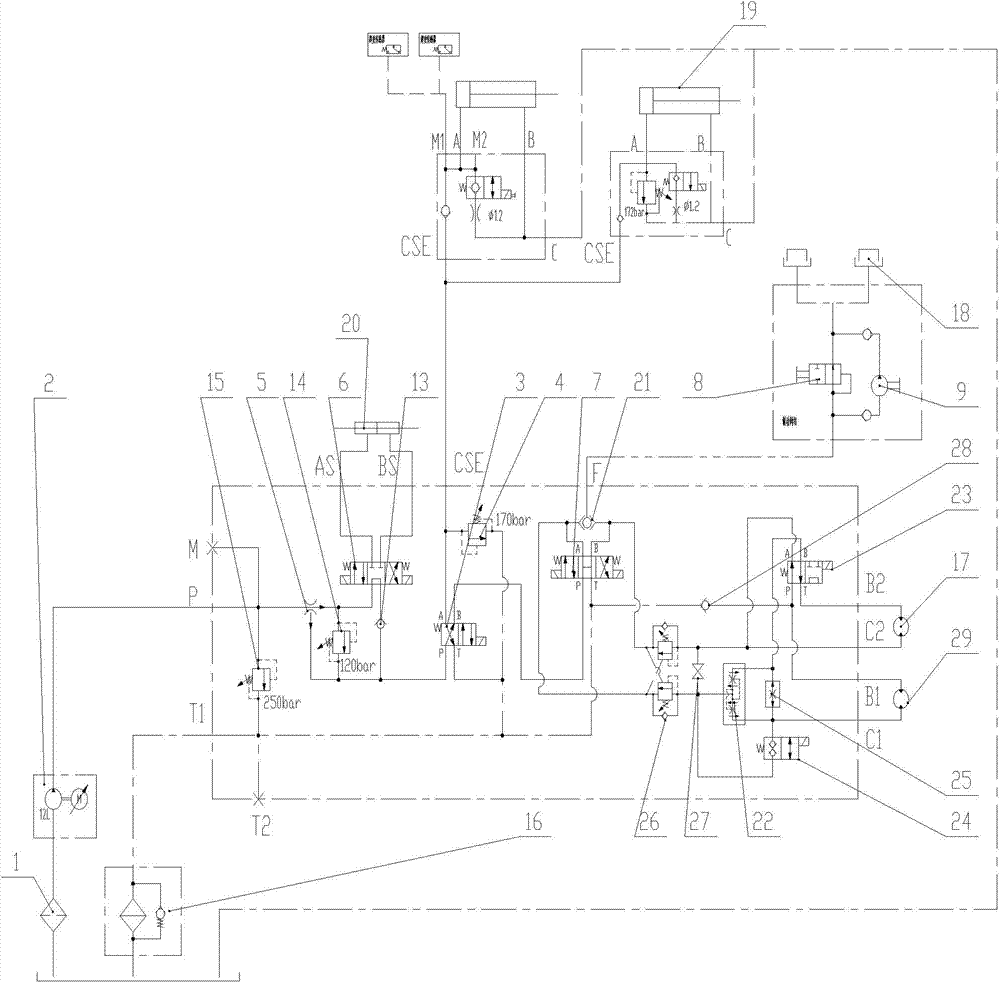

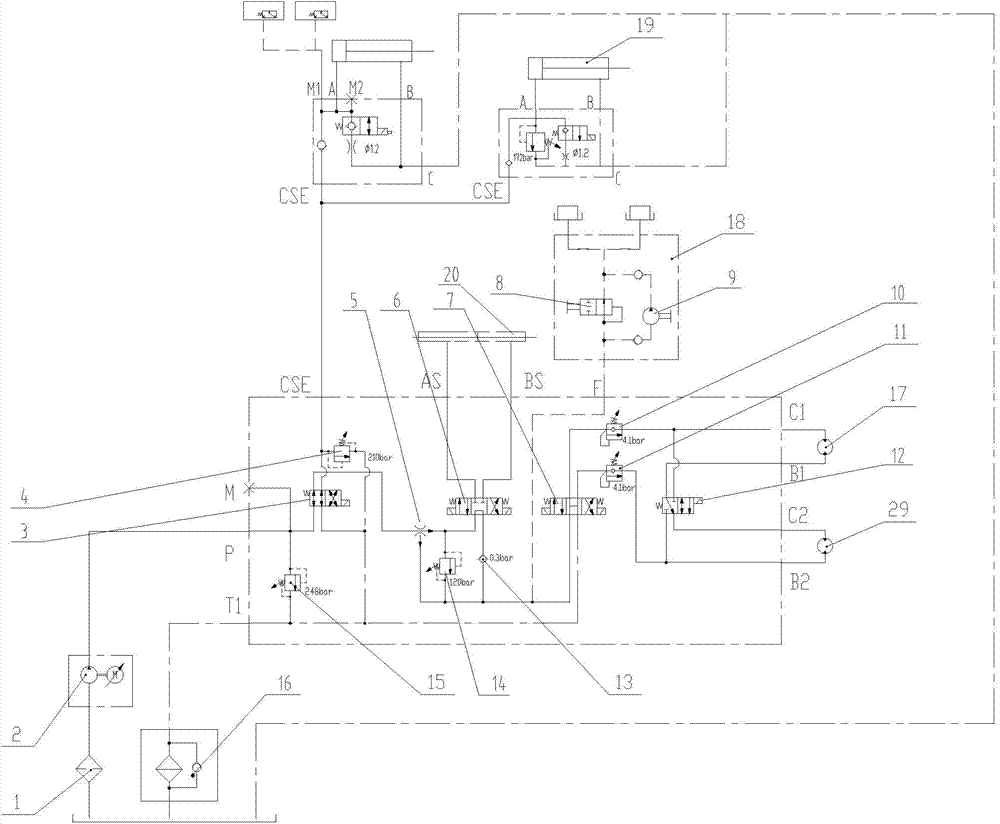

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] see figure 1 , the existing scissor-type aerial work vehicle walking hydraulic system, including oil suction filter 1, power unit 2, lift two-position four-way electromagnetic reversing valve 3, lift relief valve 4, priority valve 5, steering three-position Four-way electromagnetic reversing valve 6, three-position four-way electromagnetic reversing valve 7, brake hydraulic control reversing valve 8, brake manual pump 9, one-way valve 13, steering relief valve 14, relief valve 15, return Oil filter 16, first travel motor 17, travel brake 18, lift cylinder 19, steering cylinder 20, first solenoid valve 23, second solenoid valve 24, constant flow spool 25, balance valve 26, stop valve 27, The first one-way valve 28 and the second travel motor 29, the hydraulic system is supplied with hydraulic oil by the power unit 2, the hydraulic oil enters the main valve block, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com