Sludge treatment method and device

A kind of sludge treatment and sludge technology, which is applied in the field of sludge treatment to realize high efficiency and energy saving of sludge resource disposal, and can solve the problems of high purchase cost of equipment pipeline filter system, reduction of equipment investment and operation cost, large floor area, etc. problems, to achieve the effect of meeting the requirements of moisture content, reducing investment costs, and reducing shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

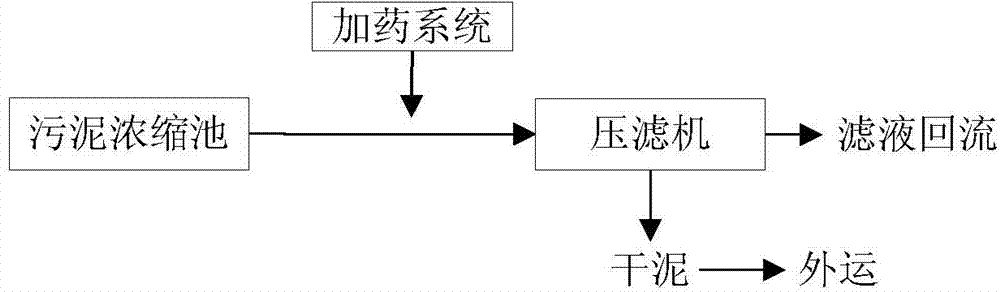

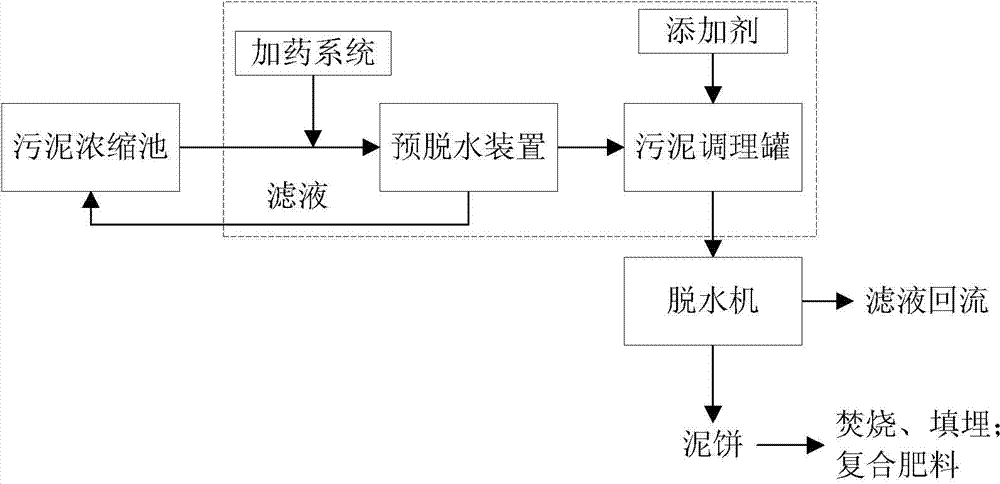

Problems solved by technology

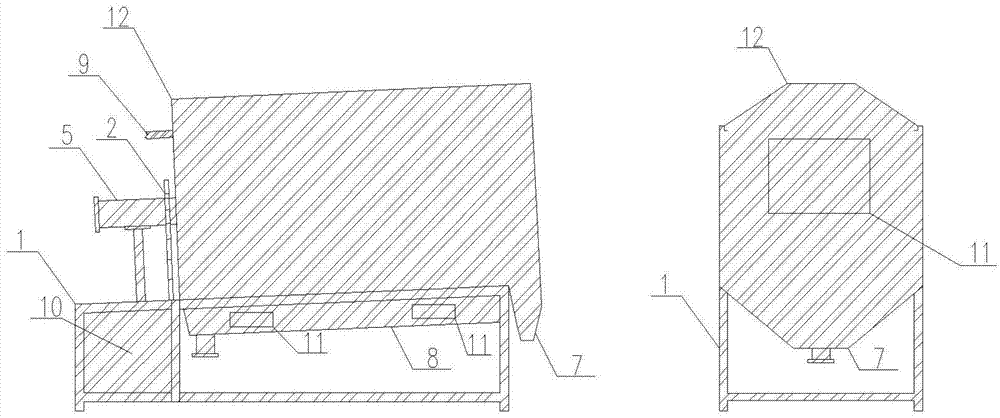

Method used

Image

Examples

Embodiment 1

[0033] An alcohol wastewater flow rate of 1000m 3 / d, the water content of the sludge in the sludge thickening tank is 98%, the pH is 7.5, and it is dehydrated by normal pressure filtration to a water content below 80%.

[0034] The sludge in the thickening tank with a water content of 98% is pretreated by coagulation and then enters the pre-dehydration device for concentration. The rotational speed of the pre-dehydration device is 0.3m / s. After dehydration, the water content of the sludge is 90.1%, and the volume becomes 1 of the original volume. / 5. After thickening, the sludge enters the sludge tank. After conditioning, the dehydration performance of the sludge is significantly improved, and the moisture content of the filter cake is reduced to 40% after dehydration. Due to the high organic content and high calorific value of alcoholic sludge, the calorific value of dry sludge is 14.7968MJ / kg, and the calorific value required for gasification with 40% low moisture content i...

Embodiment 2

[0036] A municipal sewage treatment plant has a flow rate of 100,000m 3 / d, the water content of the sludge in the sludge thickening tank is 97.8%, the pH is 7.0, and the water content is below 80% through normal pressure filtration and dehydration.

[0037] The sludge in the thickening tank with a water content of 97.5% is pretreated by coagulation and then enters the pre-dehydration device for concentration. The rotational speed of the pre-dehydration device is 0.35m / s. After dehydration, the water content of the sludge is 90.7%, and the volume becomes 23.56% of the original volume. %, after concentration, the sludge enters the sludge adjustment tank, and after conditioning, the moisture content of the filter cake drops to 43.2% after the sludge is dehydrated. The calorific value of dry-based sludge is 9.7968MJ / kg, and the calorific value required for gasification with a low moisture content of 43.2% is 1620kJ / kg, which cannot meet the energy balance of gasification. By mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com