Method of catalyzing fructose by cellulose base sulfonic acid catalyst to prepare 5-hydroxymethyl furfural

A technology of hydroxymethylfurfural and cellulose, applied in the field of biomass chemical utilization, can solve the problems of low resource utilization, waste acid, large energy input, etc., and achieve the effects of large solubility, easy operation, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 4.5g of dried α-cellulose into isopropanol / water (36mL isopropanol+4mL deionized water), add 5.2mL of 30% by mass sodium hydroxide solution drop by drop, and stir at room temperature for 3h. Add 1,4-butane sultone in acetone solution (7.6g 1,4-butane sultone dissolved in 7.6mL acetone), and react at 45°C for 6h. After standing at room temperature for 12 hours, pour it into methanol and neutralize it to neutral with acetic acid. The product was filtered, washed three times with methanol, dried under vacuum at room temperature for 12 h, and then added with 4 mol / L H 2 SO 4 Proton exchange was carried out in the solution, and the exchange was repeated 3 times. The obtained catalyst was washed with deionized water until neutral, washed with methanol, and dried under vacuum at room temperature for 24 hours to obtain a white powder cellulose-based sulfonic acid catalyst PC-SO with 1,4-butane sultone as the sulfonic acid source 3 H-1. The preparation process is as foll...

Embodiment 2

[0037] Take 4.5g of dry α-cellulose and put it into 20mL of chloroform, add the chlorosulfonic acid solution in chloroform (which contains 3.24g of chlorosulfonic acid) dropwise at 0°C, and continue to stir until the system is HCl was completely released in the medium, the reaction solution was filtered, washed 3 times with chloroform to obtain a white powder, and dried in vacuum for 12 hours to obtain a cellulose-based sulfonic acid catalyst SC-SO with chlorosulfonic acid as a sulfonic acid source 3 H-1. The preparation process is as follows:

[0038]

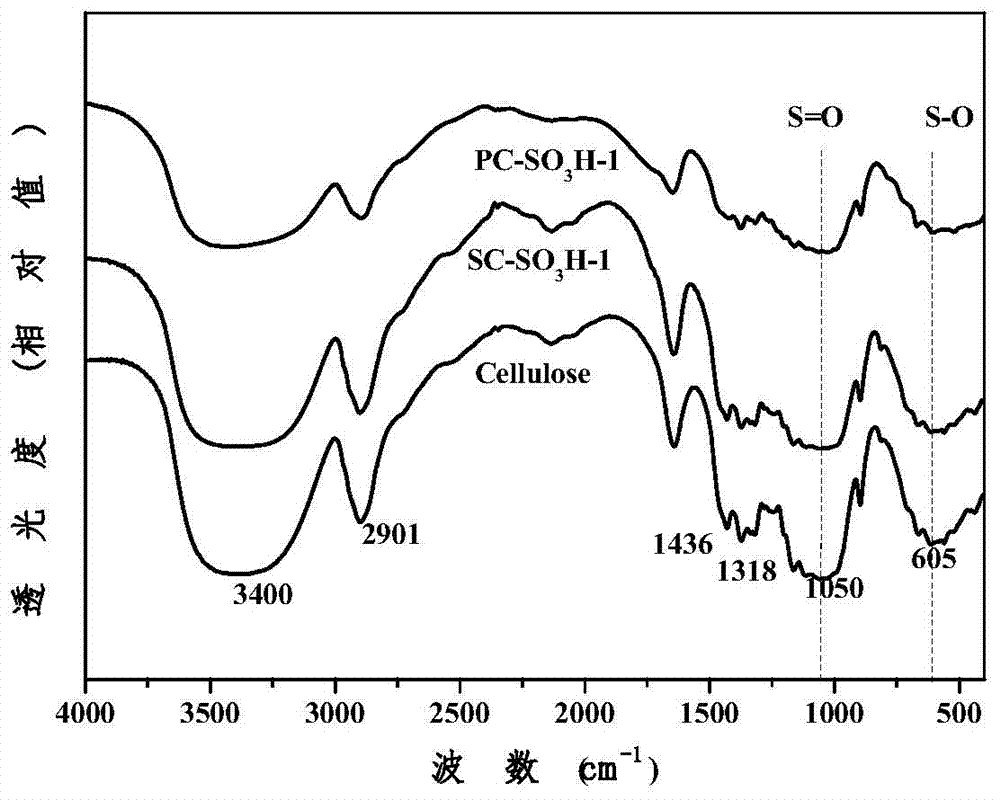

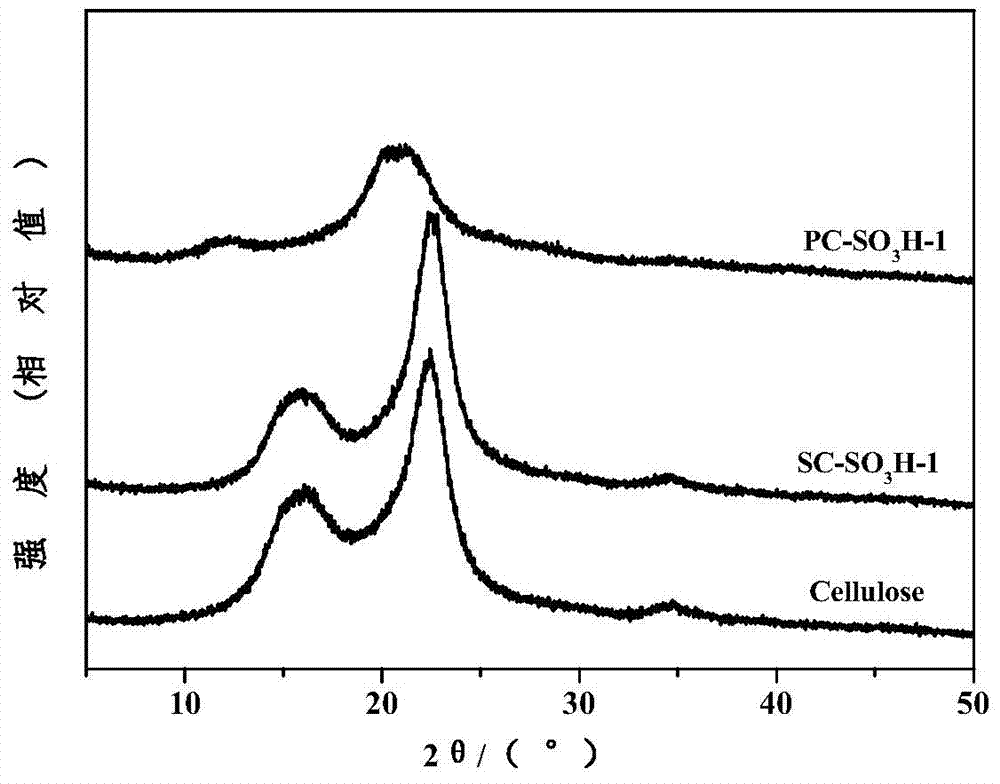

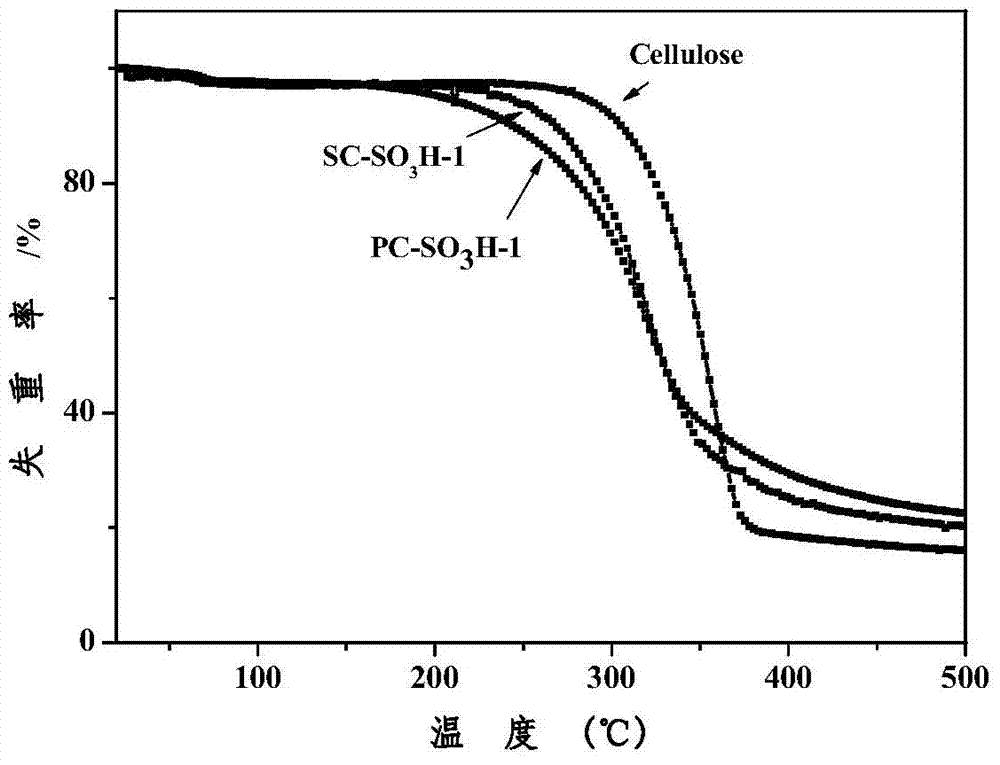

[0039] The prepared catalyst was subjected to FTIR (such as figure 1 ), XRD (such as figure 2 ), TG characterization (such as image 3 ) and elemental analysis proved -SO 3 The H group was successfully connected to the cellulose, and the S content was 0.1031mmol / g, acid-base titration showed that the H + The content is 0.1005mmol / g.

[0040] Weigh 1.0 g of fructose, 0.2 g of the above catalyst in a 25 mL hydrothermal...

Embodiment 3

[0042] Weigh 0.9 g of fructose and 0.3 g of the catalyst obtained in Example 2 into a 25 mL hydrothermal reactor, add 10 mL of isopropanol as a solvent, stir magnetically, and react at 110° C. for 1 h. After the reaction was over, the stirring was stopped, and the reactor was quickly removed to cool with water. Filter the reaction solution, wash the catalyst with isopropanol (3×5mL), distill the filtrate at room temperature at 90°C to obtain the solvent isopropanol, add 5mL of deionized water to the distilled product, and extract with ethyl acetate (3× 10 mL), the two phases were made to constant volume, and the conversion rate of fructose and the yield of 5-HMF were measured. The conversion rate of fructose was 81.29%, and the yield of 5-HMF was 6.53%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap