Sealing protection structure for road bridge expansion device

A technology of telescopic devices and protective structures, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of increased safety hazards for maintenance workers, open circuit construction, uneven road surface temperature, etc., so as to reduce daily maintenance and cleaning work, improve damping and reduce The vibration function and the effect of reducing the impact of car jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

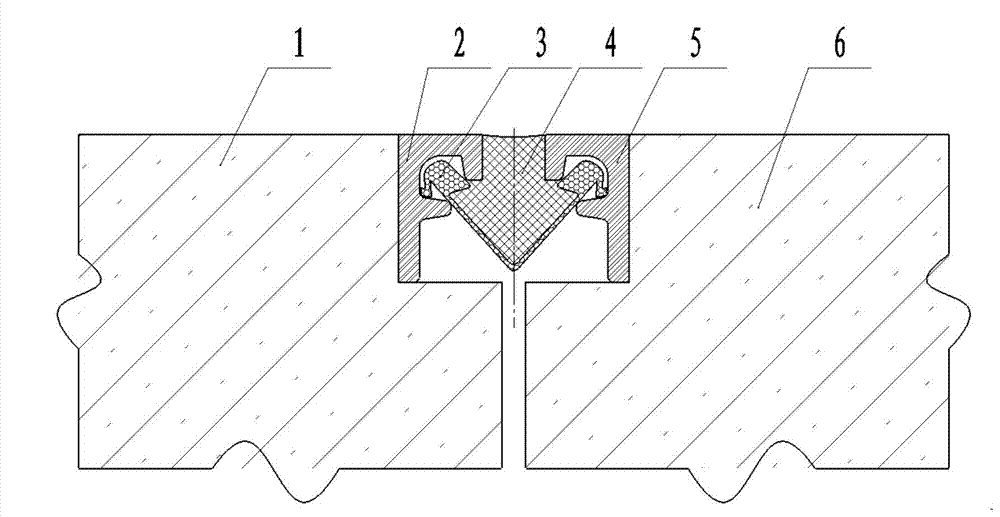

[0016] Such as figure 1 , special-shaped steel 2 adopts "F" steel, and the expansion device composed of special-shaped steel 2 and 5 and sealing rubber belt 3 is filled with elastic filling material 4. Special-shaped steel 2 and 5 are embedded in the top of bridge beam body 1 and 6, and the Expansion joints are formed on 1 and 6, and the sealing rubber belt 3 is embedded on the special-shaped steel 2 and 5 on both sides. The upper part of the sealing rubber belt 3 forms a V-shaped space, and the elastic filling material 4 is placed in the V-shaped space formed on the upper part of the sealing rubber belt 3. , flush with the top surfaces of the bridge girders 1 and 6, and the elastic filling material 4 and the special-shaped steel 2 and 5 are bonded together.

[0017] The elastic filling material 4 is polysulfide sealant, which is filled into the expansion joint and vulcanized naturally into an elastic body.

Embodiment 2

[0019] Below in conjunction with the embodiment schematically provided of accompanying drawing, describe the present invention in detail, wherein:

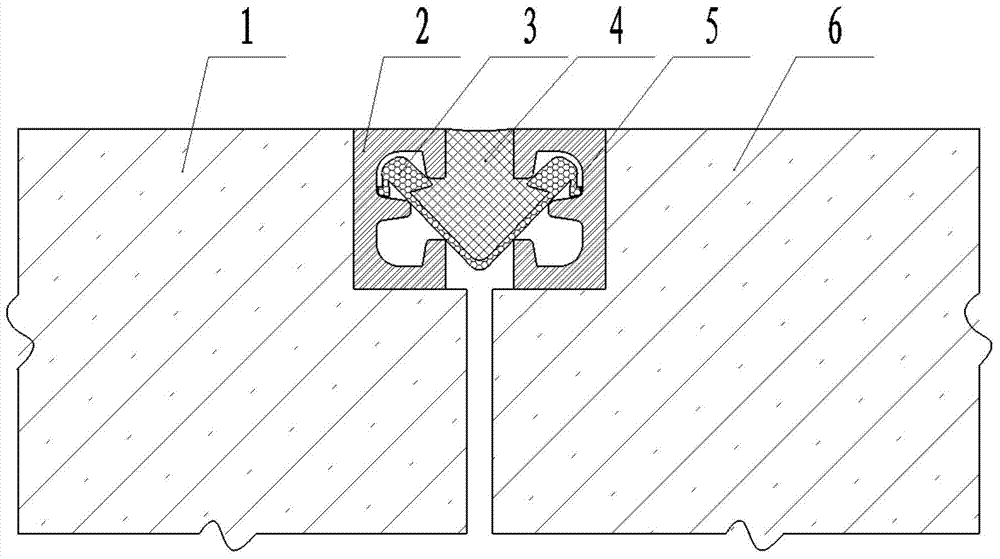

[0020] Such as figure 2 The special-shaped steel 2 adopts "E"-shaped steel, and the telescopic device composed of the special-shaped steel 2 and 5 and the sealing rubber belt 3 is filled with elastic filling material 4. The special-shaped steel 2 and 5 are embedded in the top of the bridge beam body 1 and 6. Expansion joints are formed on 1 and 6, and the sealing rubber belt 3 is embedded on the special-shaped steel 2 and 5 on both sides. The upper part of the sealing rubber belt 3 forms a V-shaped space, and the elastic filling material 4 is placed in the V-shaped space formed on the upper part of the sealing rubber belt 3. , flush with the top surfaces of the bridge girders 1 and 6, and the elastic filling material 4 and the special-shaped steel 2 and 5 are bonded together.

[0021] The elastic filling material 4 is silicone s...

Embodiment 3

[0023] Below in conjunction with the embodiment schematically provided of accompanying drawing, describe the present invention in detail, wherein:

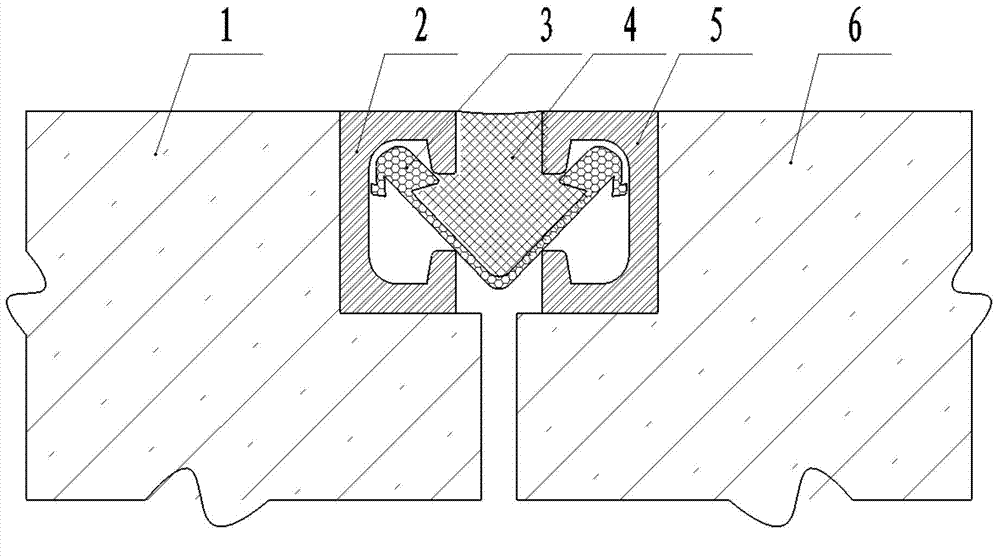

[0024] Such as image 3 The special-shaped steel 2 adopts "C" steel, and the expansion device composed of the special-shaped steel 2 and 5 and the sealing rubber belt 3 is filled with elastic filling material 4, and the special-shaped steel 2 and 5 are embedded in the top of the bridge beam body 1 and 6. Expansion joints are formed on 1 and 6, and the sealing rubber belt 3 is embedded on the special-shaped steel 2 and 5 on both sides. The upper part of the sealing rubber belt 3 forms a V-shaped space, and the elastic filling material 4 is placed in the V-shaped space formed on the upper part of the sealing rubber belt 3. , flush with the top surfaces of the bridge girders 1 and 6, and the elastic filling material 4 and the special-shaped steel 2 and 5 are bonded together.

[0025] The elastic filling material 4 is polyurethane se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com