Rotation-driven swing valve type continuous wave generator

A wave generator and rotary drive technology, applied in the field of continuous wave generators, can solve problems such as rotor jamming, achieve the effects of improving drilling safety, simple structure, and reducing the risk of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

[0044] In the embodiments of the present invention, for the convenience of description, the relative positional relationship of each component is described according to the layout of the drawings in the description, for example: the upper and lower positional relationship is determined according to the layout of the parts in the drawings of the description .

[0045] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

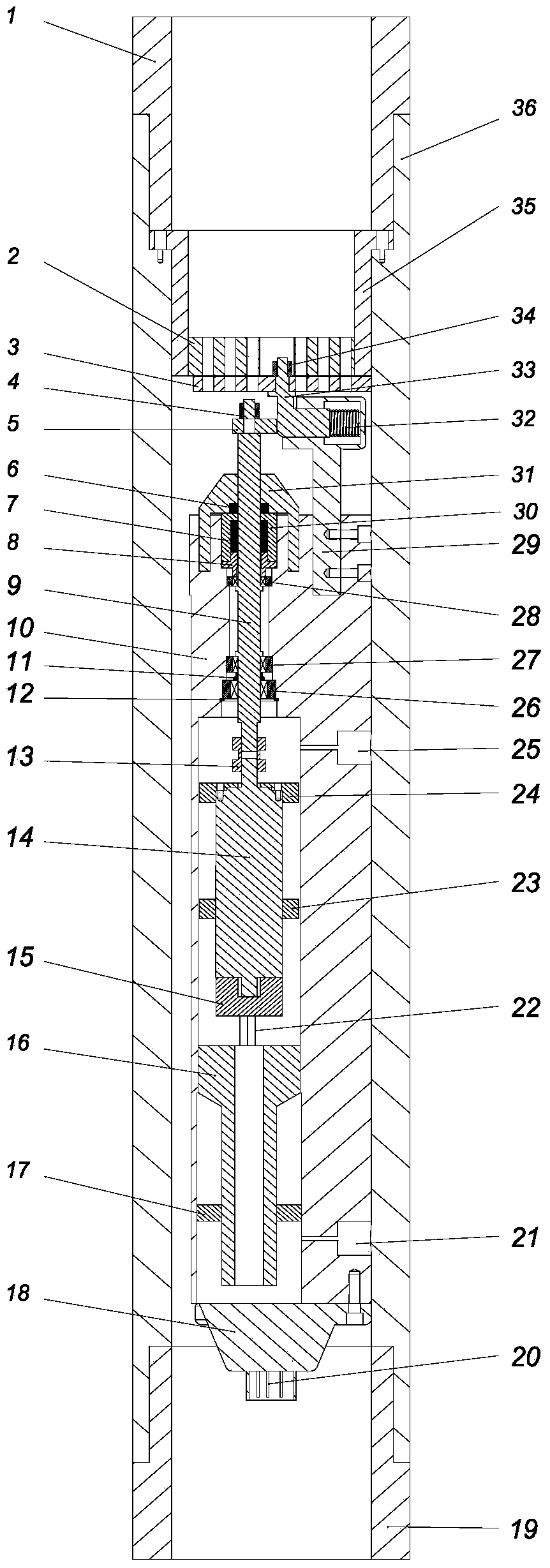

[0046] Such as figure 1 As shown, a shear valve continuous wave generator driven by rotation includes a drill collar 36 and a continuous wave generating unit installed in the drill collar 36, a rotation-swing conversion mechanism, a power output unit, a sealing module, and a pressure balance module and electrical connection modules.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com