Automatic exhaust system of clutch and exhaust method implemented by automatic exhaust system

An automatic exhaust and clutch technology, applied to clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve problems such as poor environmental protection, low economic efficiency of transmission media, manual exhaust time-consuming and labor-intensive safety, etc., to achieve safety Improvement of performance and reliability, elimination of the possibility of failure, remarkable exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

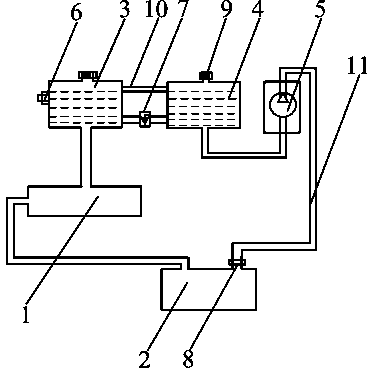

[0036] Such as figure 1 As shown, this implementation takes the air brake type clutch operating system as an example to describe the present invention in detail. The clutch automatic exhaust system mainly includes clutch master cylinder 1, clutch slave cylinder 2, liquid storage tank 3, compensation tank 4 and electric oil pump 5, wherein, compensation tank 4, electric oil pump 5, clutch slave cylinder 2, clutch master cylinder 1 and the liquid storage tank 3 are connected in sequence through the infusion pipeline 11, while the liquid storage tank 3 and the compensation tank 4 are connected through a conduit, and a check valve 7 is installed on the conduit, so that a medium is formed between each device flow loop. At the same time, an air conduit 10 is provided between the liquid storage tank 3 and the compensation tank 4 for gas flow between the liquid storage tank and the compensation tank. Considering that the gas must stay on the upper part of the liquid storage tank 3, ...

Embodiment 2

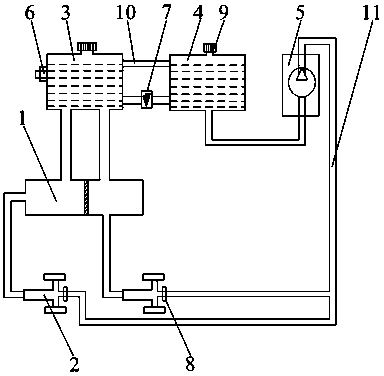

[0041] Such as figure 2 As shown, the present embodiment takes the hydraulic brake system single cylinder model as an example to illustrate the present invention. The difference from Embodiment 1 is that the brake cylinder includes a front cylinder and a rear cylinder, and the front cylinder and the rear cylinder The pumps are respectively provided with connecting bolts, and check valves are installed on the connecting bolts; the brake master cylinder is divided into a master cylinder front chamber and a master cylinder rear chamber, and the front sub-cylinder communicates with the liquid storage tank and the master cylinder front chamber respectively , and the rear slave pump is respectively connected with the liquid storage tank and the rear cavity of the master cylinder. The infusion pipeline coming out from the oil pump is respectively connected with the check valves on the front sub-pump and the rear sub-pump. As for the arrangement between the liquid storage tank, the c...

Embodiment 3

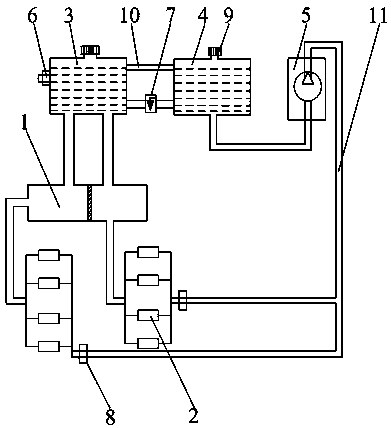

[0044] Such as image 3 As shown, this embodiment takes the hydraulic braking system double cylinder model as an example to illustrate the present invention. The pump belongs to the existing technology, not the design innovation of this technology, and this technology does not need to change the brake cylinder, so the above process will not be repeated here.

[0045] The invention can also be applied to the hydraulic braking system to realize the automatic exhaust of the hydraulic braking system. It should be noted that, from the above embodiments, it can be seen that the present invention can be applied to various clutch operating systems, and can realize automatic exhaust in a safe, convenient and efficient manner without affecting the normal operation of the clutch operating system. Its practical value and market prospect are very high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com