Self-energizing magnetorheological fluid brake device capable of recycling brake energy

A braking energy recovery, magnetorheological fluid technology, applied in the direction of brake type, electric braking system, brake actuator, etc., can solve the problem of poor heat dissipation performance of magnetorheological fluid, increase the complexity of the brake structure, Increase the difficulty of brake control and other problems to achieve the effect of simple structure, improved braking torque and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

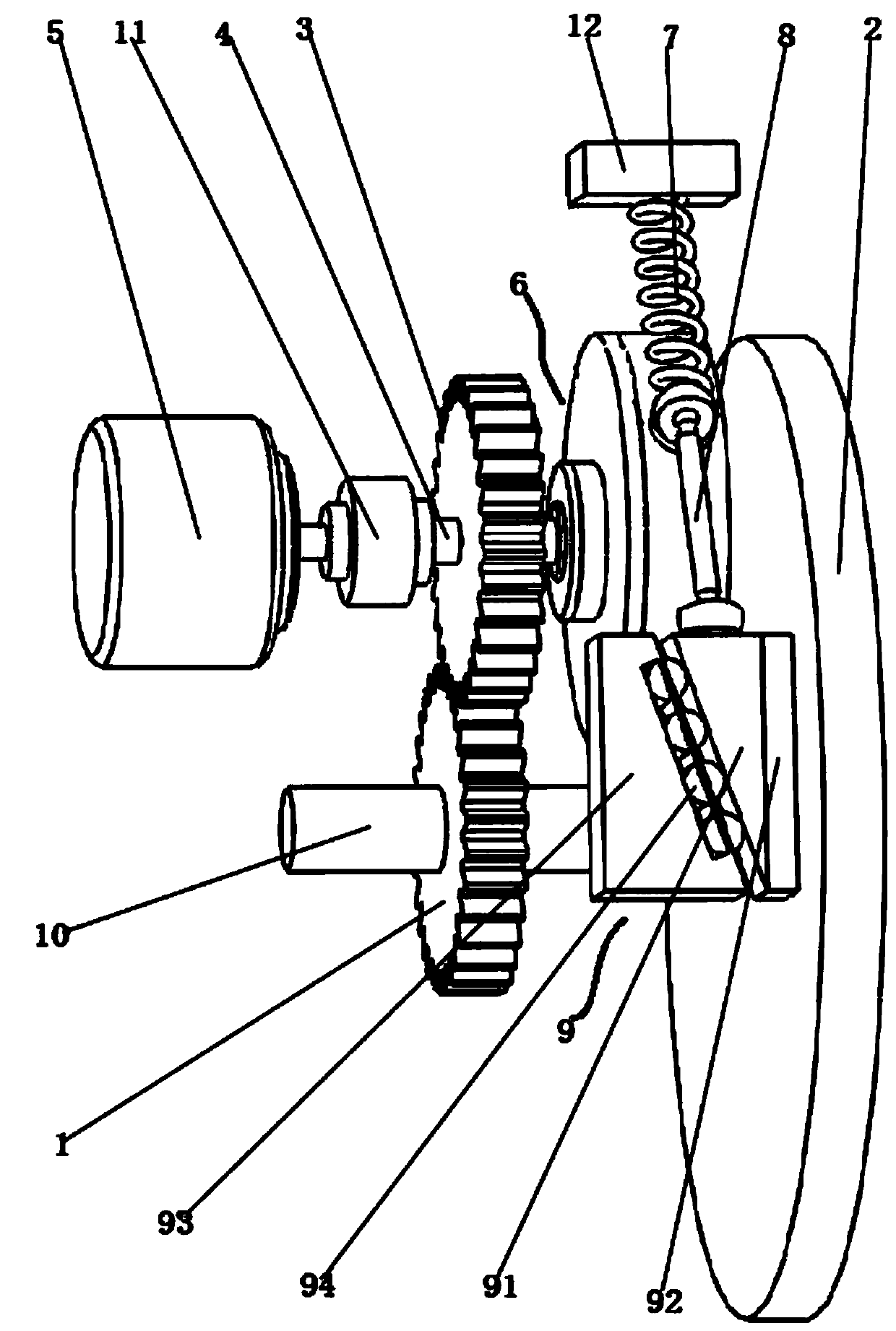

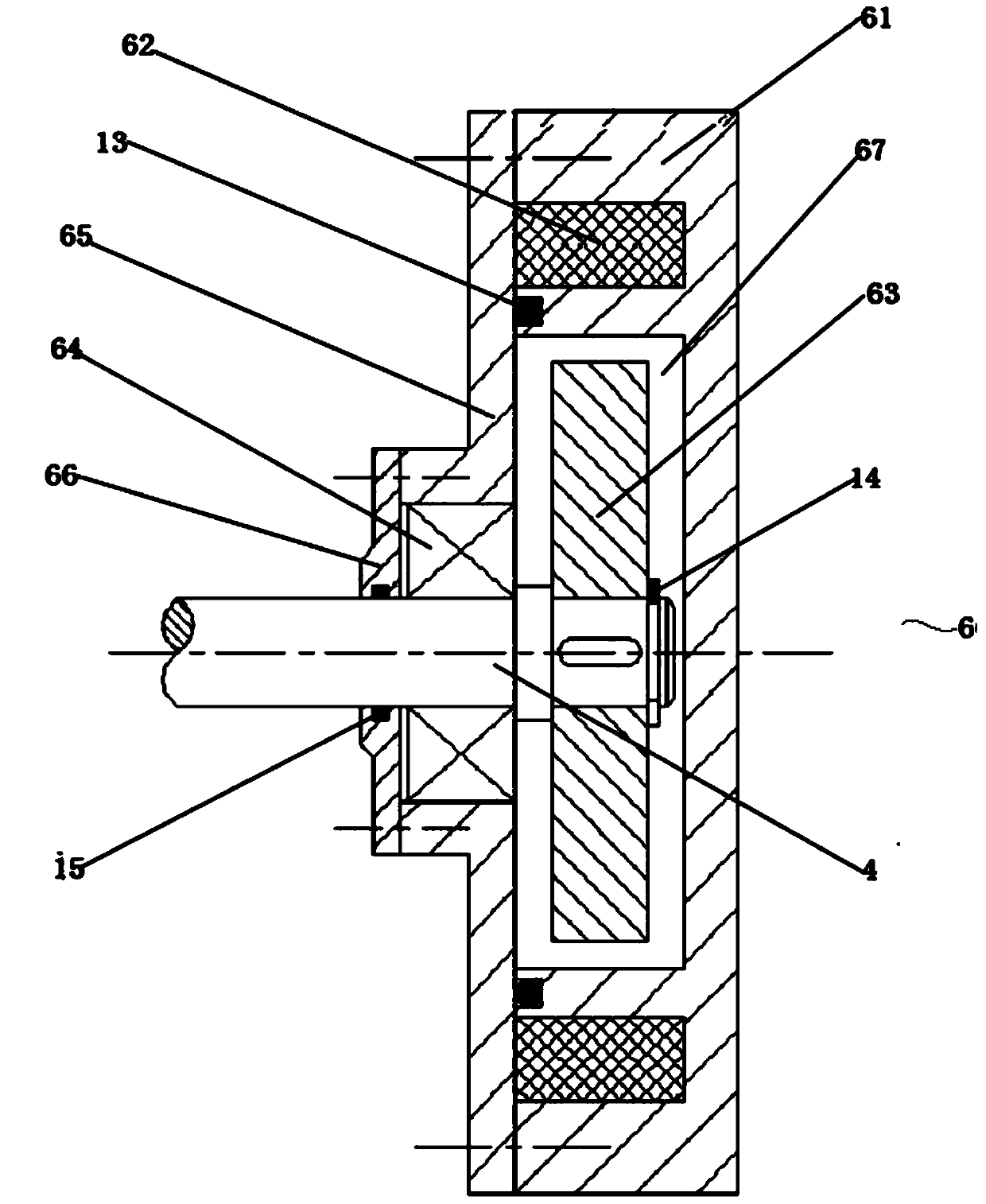

[0014] like figure 1 As shown, the present invention includes a driving gear 1 , a brake disc 2 , a driven gear 3 , a driven shaft 4 , a motor 5 , a magneto-rheological device 6 , a return spring 7 , a connecting rod 8 and a wedge-shaped self-energizing device 9 .

[0015] The driving gear 1 and the brake disc 2 are sequentially keyed to the wheel shaft 10 , and the driving gear 1 meshes with the driven gear 3 keyed to the driven shaft 4 . One end of the driven shaft 4 is rotatably connected to the motor 5 through a coupling 11 , and the other end is rotatably connected to the magneto-rheological device 6 . One end of the return spring 7 is connected to the casing of the magneto-rheological device 6 , and the other end is connected to the spring base 12 fixed on the vehicle body. One end of the connecting rod 8 is also ball-hinged to the housing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com