Lifting slewer

A technology of rotary device and rotary shaft, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., to achieve the effect of accurate positioning, small movement impact, and no dead angle of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

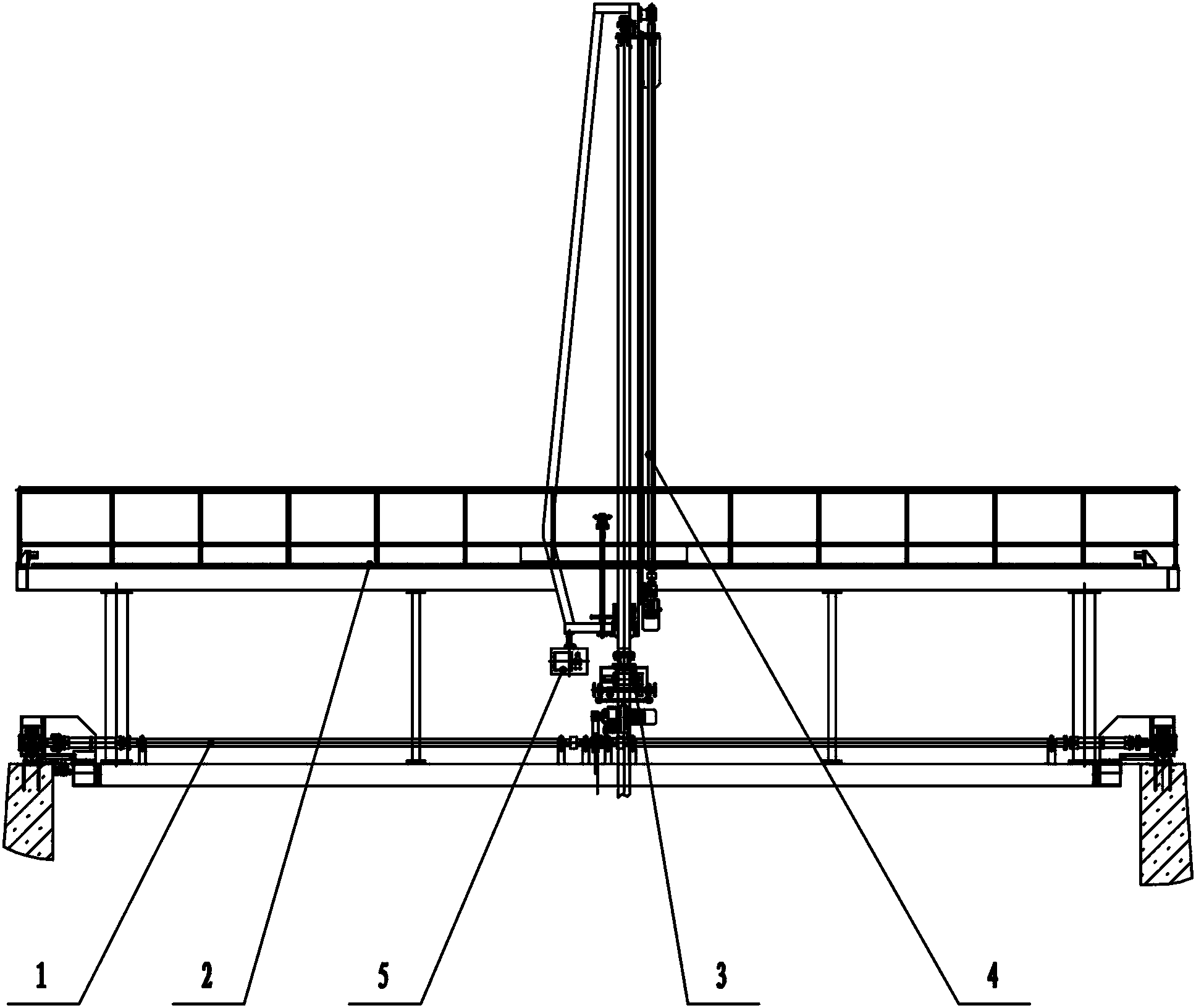

[0033] Such as figure 1 Among them, a lifting and turning device, including: a cart traveling system 1 for traveling along a guide rail;

[0034] The trolley traveling system 2 that walks on the cart traveling system 1;

[0035] Also includes: a support frame 19 installed on the trolley walking system 2;

[0036] The lifting and turning device 4 is provided on the support frame 19 .

[0037] The electrical control system 5 is an electrical control system composed of electrical control cabinets, low-voltage electrical components, and frequency conversion control systems. The whole system adopts PLC control, touch screen operation interface.

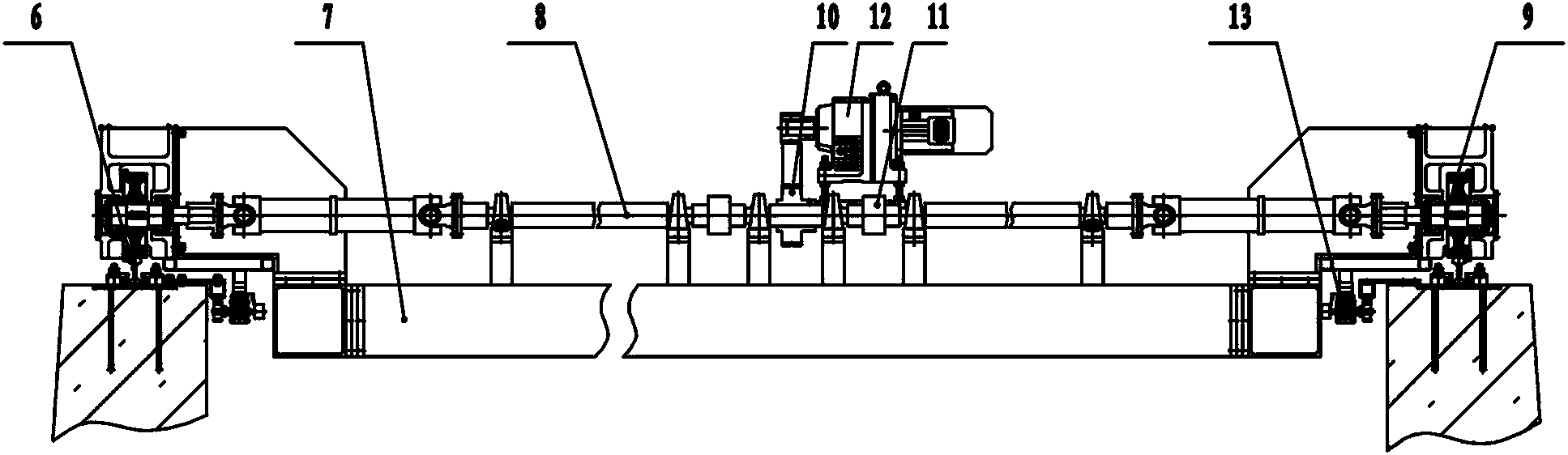

[0038] Such as figure 2 Among them, in the cart traveling system 1 described above, the cart reducer 12 installed on the cart support 7 is connected to the cart transmission shaft 8 through the cart gear transmission pair 10 and the cart coupling 11, and the cart transmission Axle 8 is connected with cart roller 9, and is used to dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com