Oscillating rotor type expansion compressor

An expansion compressor, rotor type technology, applied in the direction of swing piston type machinery, compressor, swing piston type pump, etc., can solve the problems of short life of rolling bearing and large loss of clearance volume, so as to reduce friction loss and reduce clearance. Volume loss, beneficial effect on lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

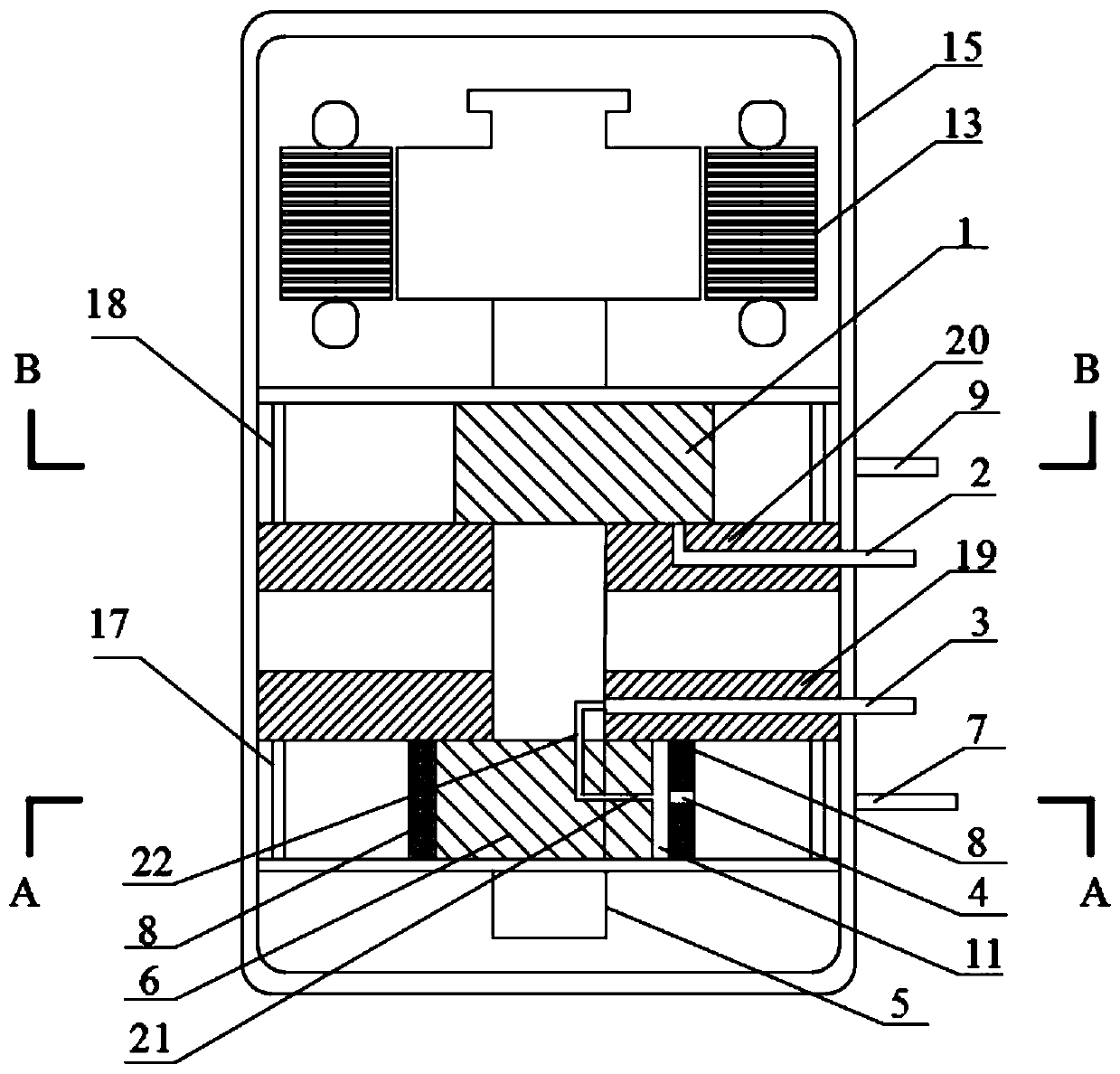

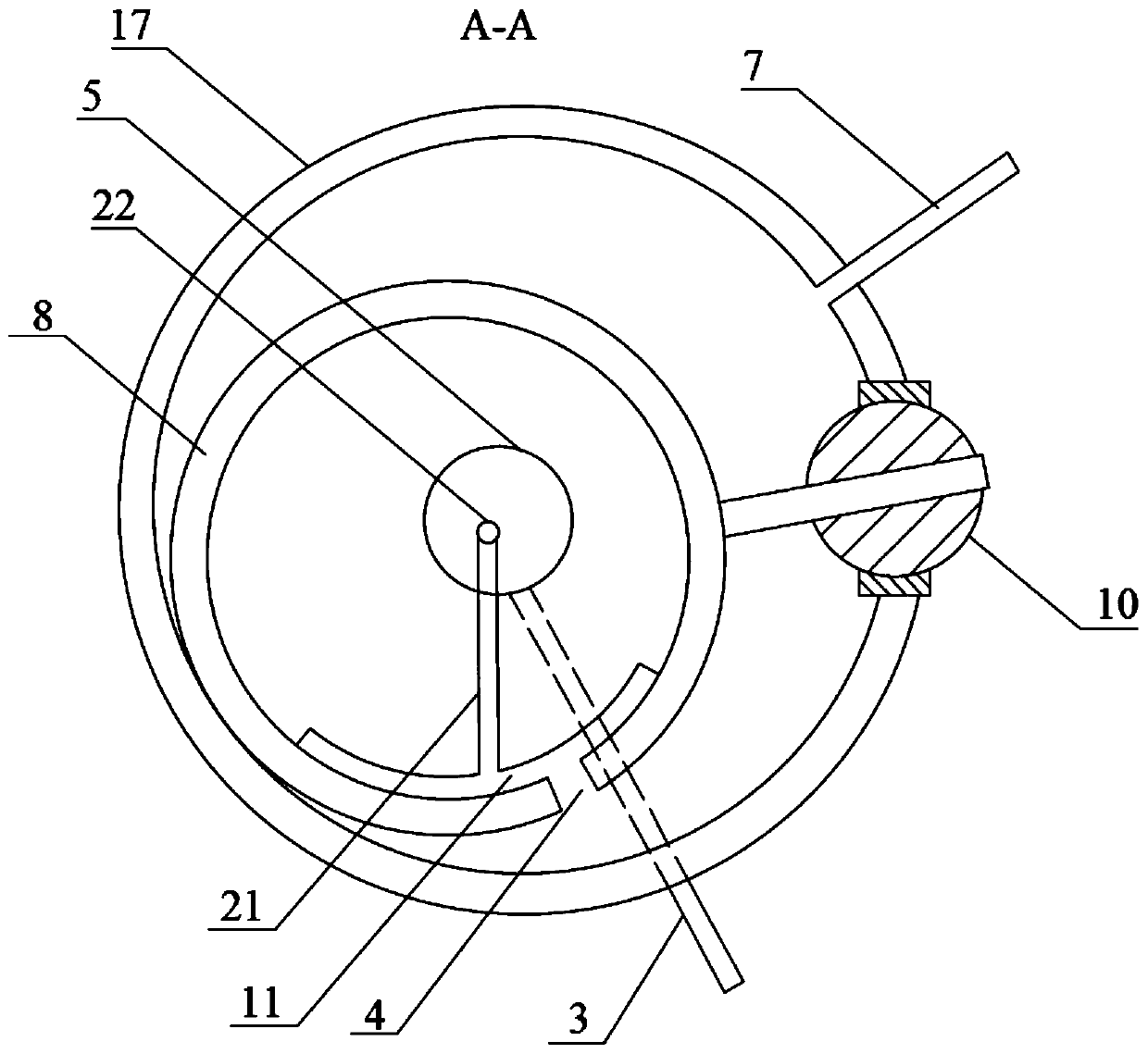

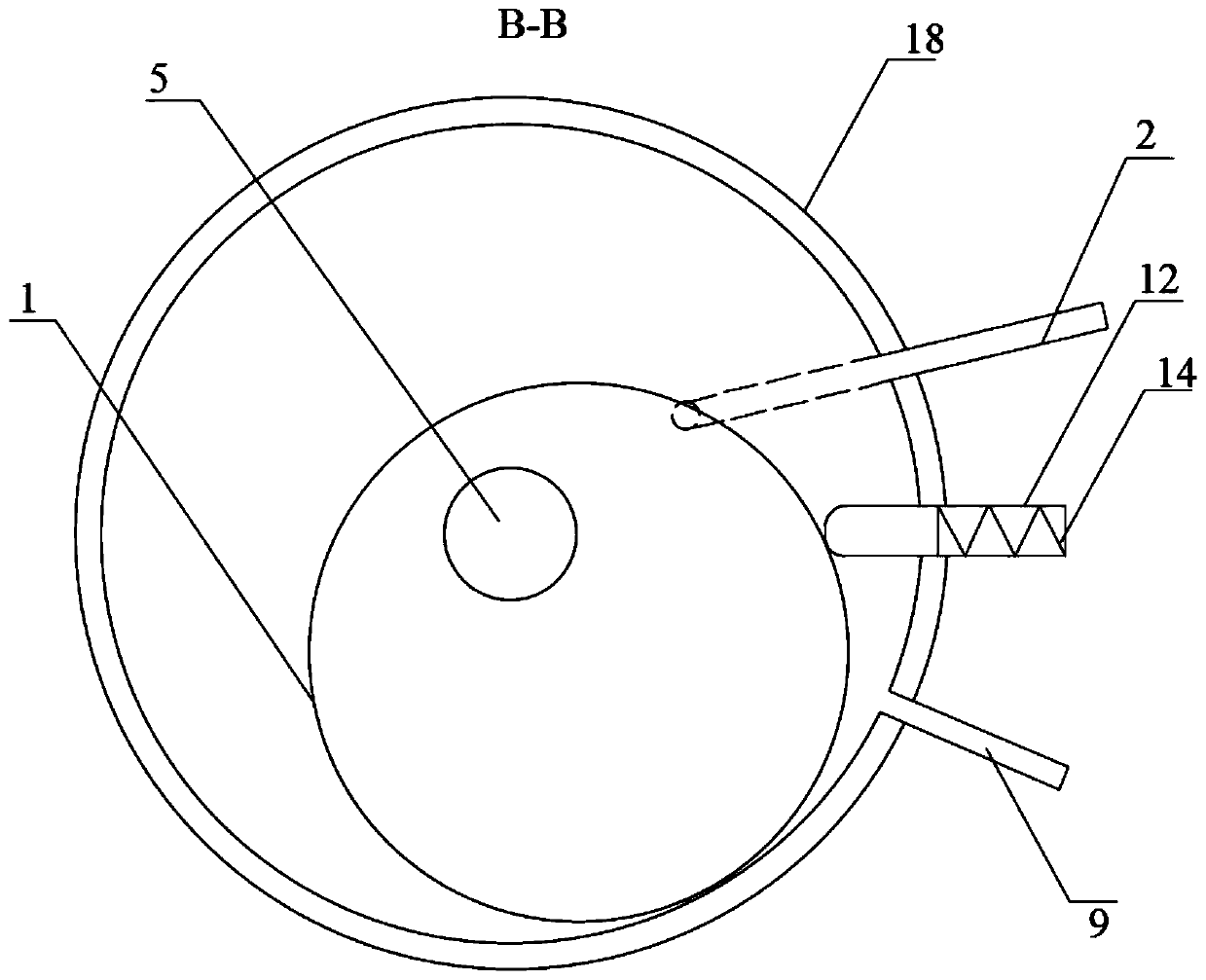

[0018] like Figure 1-3 The swing rotor type expansion compressor shown includes a housing 15, in which an expansion cylinder 17, a compression cylinder 18 and a motor 13 are arranged sequentially from bottom to top, and an expansion eccentric wheel 6 is arranged in the expansion cylinder 17, Compression cylinder 18 is provided with compression eccentric wheel 1, expansion eccentric wheel 6, compression eccentric wheel 1 and motor 13 are all fixedly connected with main shaft 5 axially arranged in the housing, in this embodiment, housing 15 is a cylinder , the main shaft 5 is parallel to the axial direction of the housing 15, the main shaft 5 runs through the expansion eccentric 6 and the compression eccentric 1, the motor 13 is fixedly installed inside the housing 15, and is used to drive the main shaft 5 to rotate, due to the expansion eccentric 6 and the compression eccentric The wheels 1 are integrated with the main shaft 5, so when the main shaft 5 rotates, both the expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com