Water dispenser with cup supporting plate lifting mechanism

The technology of a lifting mechanism and a water dispenser is applied to beverage preparation devices, household appliances, applications, etc., and can solve the problems of tea losing good taste, affecting use, and inconvenience to users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is further described.

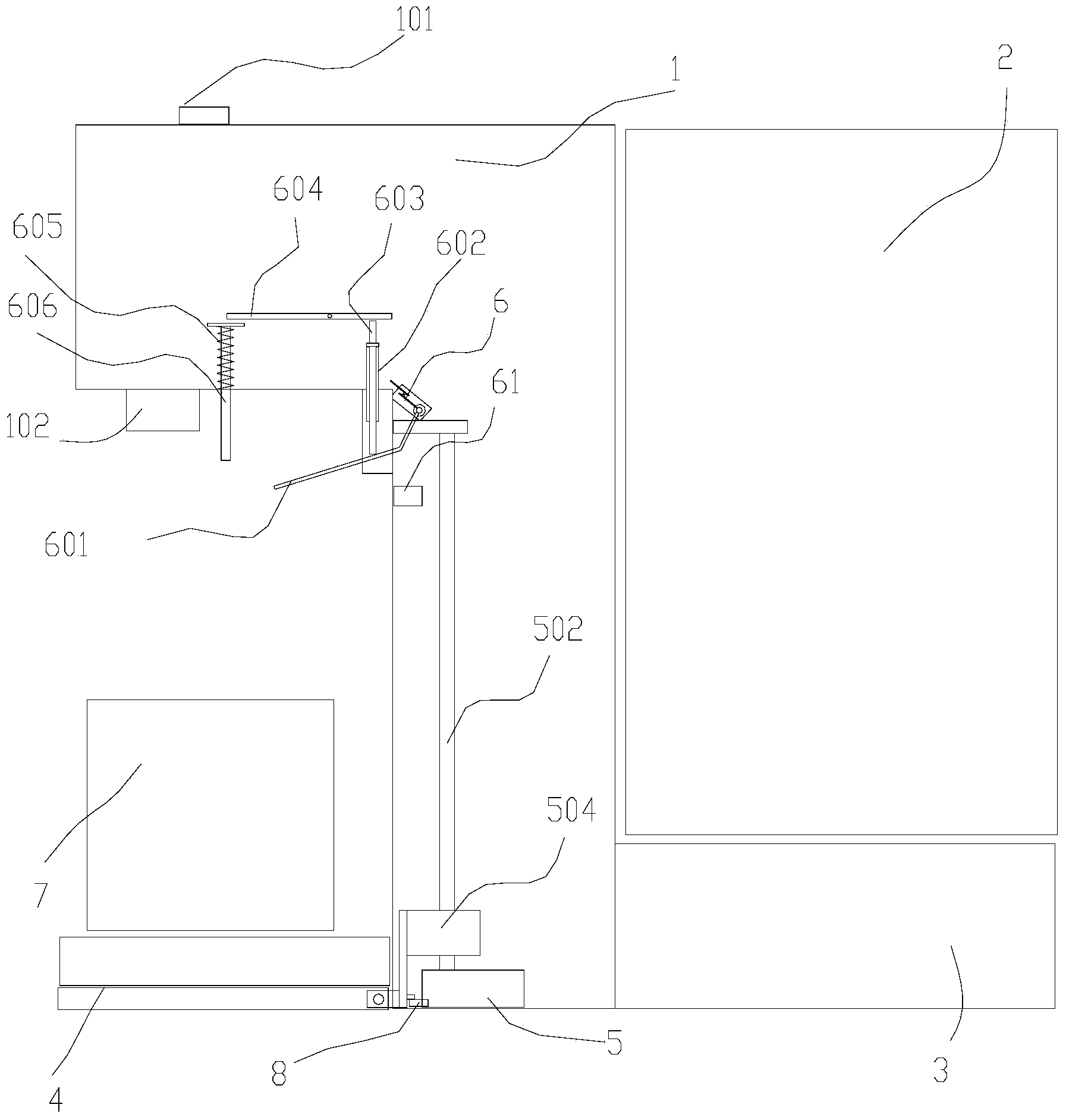

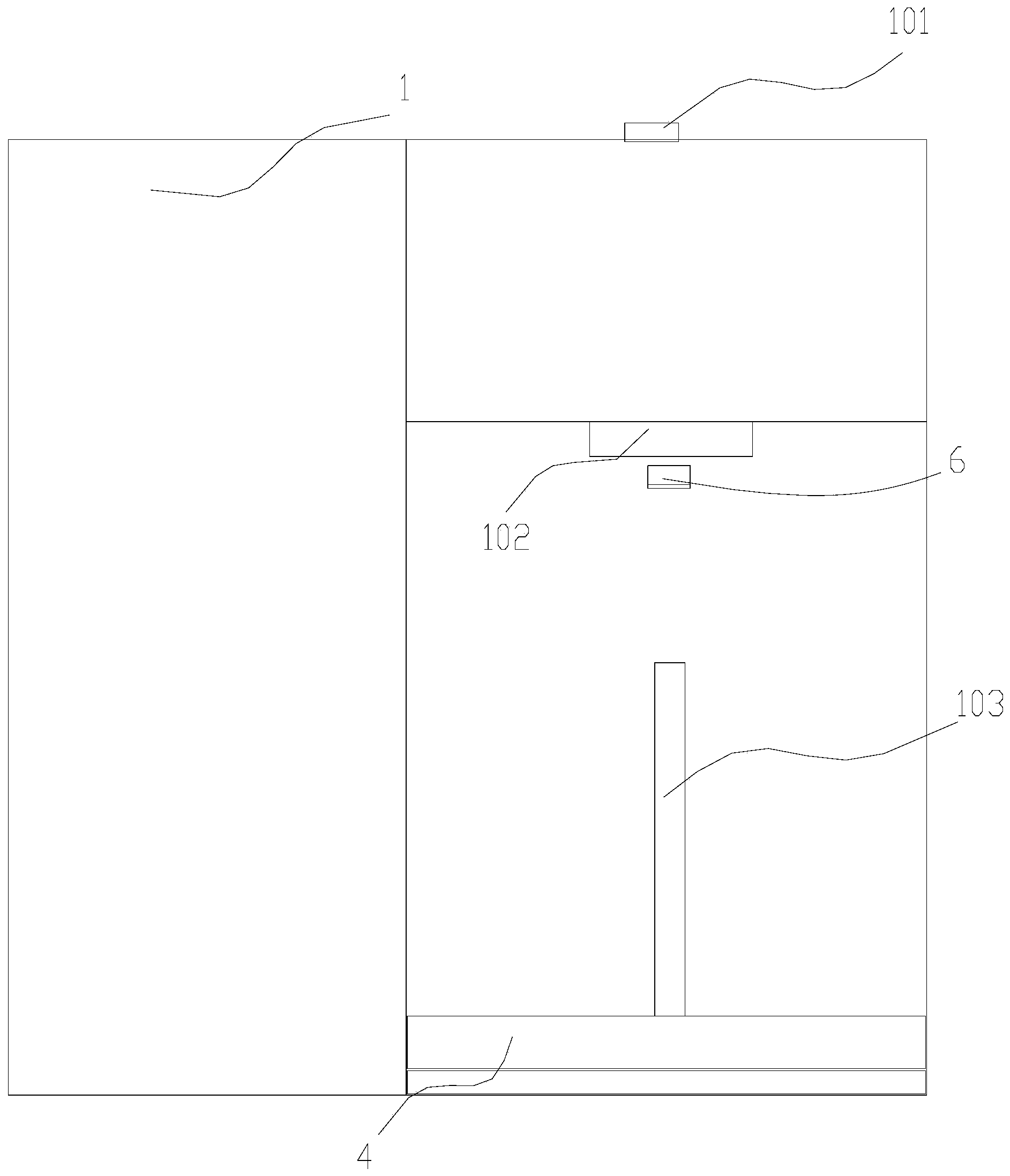

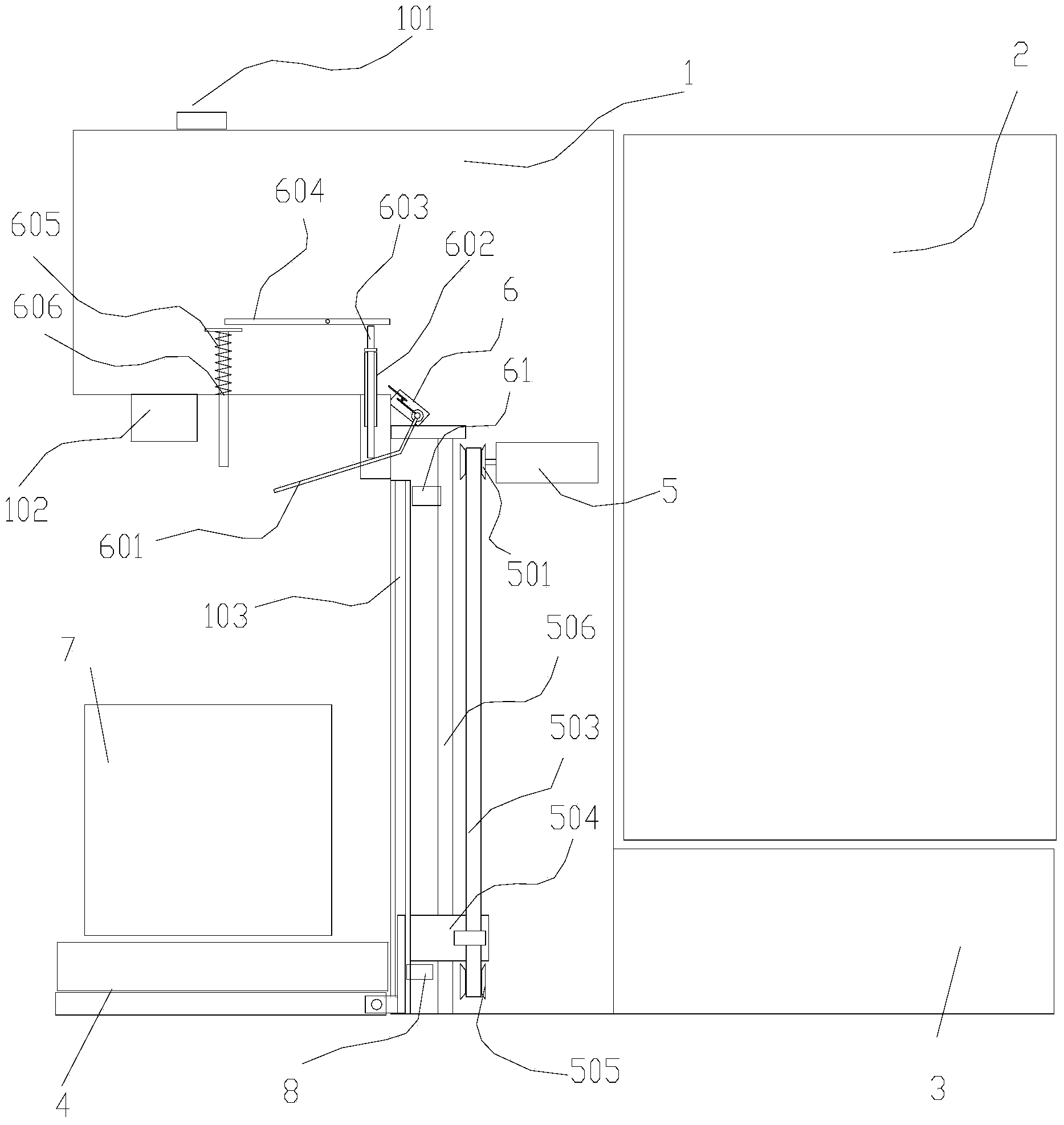

[0021] Such as figure 1 , figure 2 As shown, a water dispenser provided with a lifting mechanism for cup trays includes a machine base 1, a water tank 2, a base 3, a cup tray 4, a water cup 7 and a control circuit, the water tank 2 is arranged on the base 3, and the The base 1 is provided with a chute 103, a cup tray 4 slidingly connected with the chute 103, a cup tray drive mechanism, a water level detection device, an upper limit switch 6 and a lower limit switch 8; the upper limit switch 6 and the lower limit switch 8 are respectively fixed on the support 1, and are in the upper and lower limit positions of the stroke track of the carriage 504; 502 rotating motor 5, one end of the screw rod 502 is movably connected with the base 1, and the other end is connected with the output shaft of the motor 5, the motor 5 is fixed on the base 1, and the carriage 504 is hinged with a support cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com