Dental filling machine

A dental filling device and cylinder technology, which is applied in dentistry, tooth filling, dental prosthetics, etc., can solve the problems of frequent tool changes, and achieve the effect of saving operation time, convenient operation, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

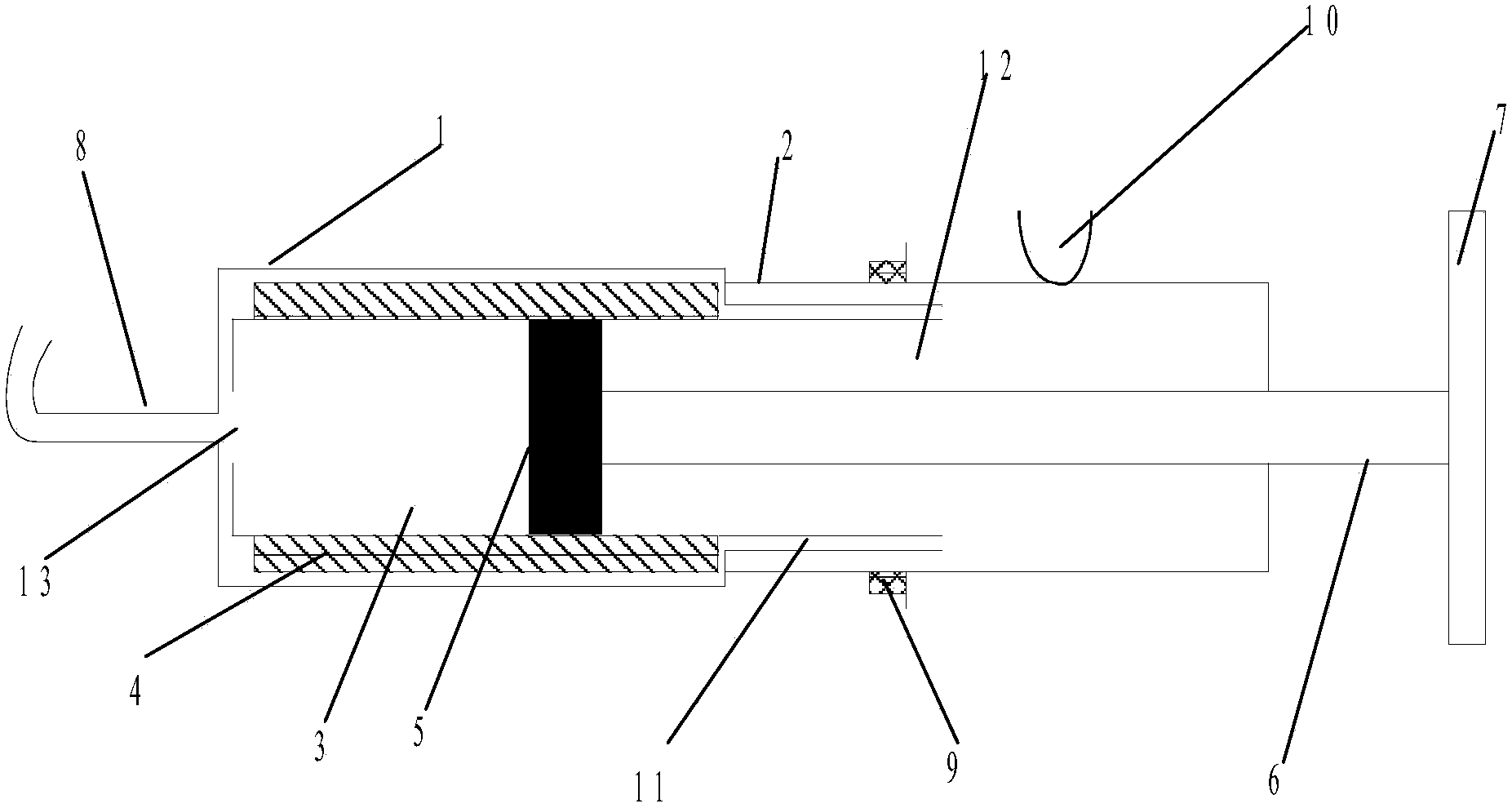

[0026] Such as figure 1 As shown, the present invention provides a dental plug, comprising:

[0027] A cylinder, which includes a first cylinder 1 and a second cylinder 2, the first end of the first cylinder 1 is provided with a needle 8, and the second end of the first cylinder 1 is sleeved on the second cylinder The first end of the second barrel 1; the needle 8 is made of memory metal material, the needle end of the needle 8 is flush, and the tail end of the needle 8 is connected to the first end of the first syringe 1 ; One side of the second cylinder 2 is provided with a slot 10, the slot 10 is U-shaped, and the slot 10 is used for clamping the hose of the teeth cleaning device.

[0028] Storage tank 3, which is arranged in the first cylinder body 1, the length of the storage tank 3 is less than 1 cm of the length of the first cylinder body 1, and the storage tank 3 has a filler inlet 12 and a filling material A material outlet 13, the filling material outlet 13 is arra...

Embodiment 2

[0036] Such as figure 1 As shown, the present invention provides a dental plug, comprising:

[0037] A cylinder, which includes a first cylinder 1 and a second cylinder 2, the first end of the first cylinder 1 is provided with a needle 8, and the second end of the first cylinder 1 is sleeved on the second cylinder The first end of the second barrel 1; the needle 8 is made of memory metal material, the needle end of the needle 8 is flush, and the tail end of the needle 8 is connected to the first end of the first syringe 1 ; One side of the second cylinder 2 is provided with a slot 10, the slot 10 is U-shaped, and the slot 10 is used for clamping the hose of the teeth cleaning device.

[0038] Storage tank 3, which is arranged in the first cylinder body 1, the length of the storage tank 3 is less than the length 3cm of the first cylinder body 1, the storage tank 3 has a filler inlet 12 and a filling material A material outlet 13, the filling material outlet 13 is arranged cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com