Large-scale energy-efficient high-efficiency cone crusher

A cone crusher, high-efficiency technology, applied in the direction of grain processing, etc., to achieve effective adjustment and positioning, reasonable design, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

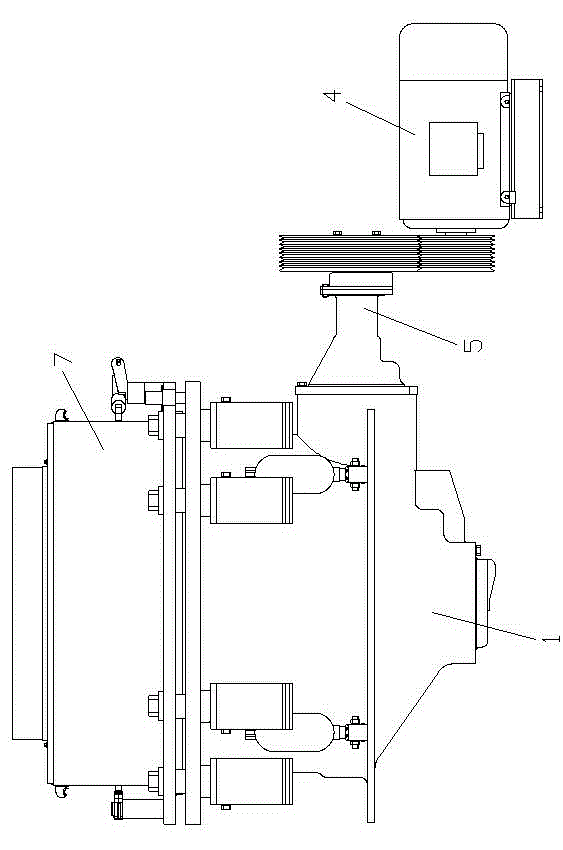

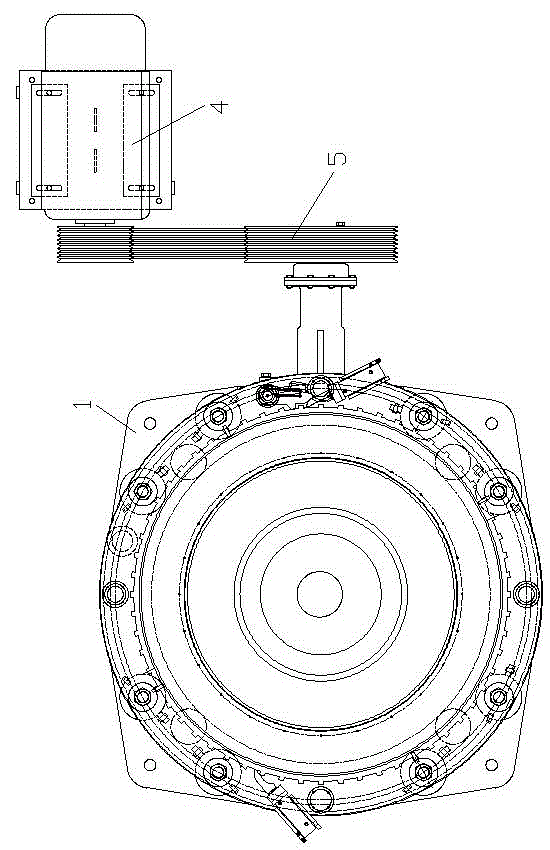

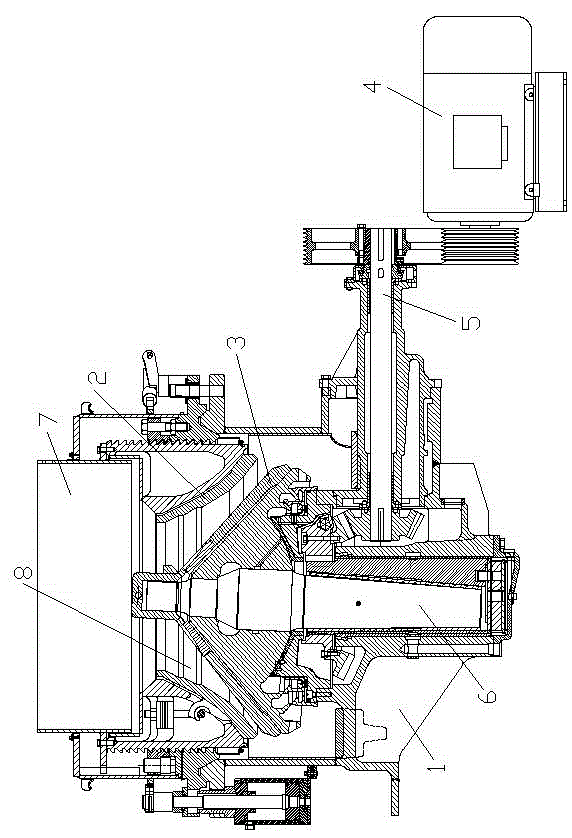

[0036] see Figure 1 to Figure 12 , the large-scale energy-saving and high-efficiency cone crusher in this embodiment includes a frame 1, an upper liner 2, a lower liner 3, a motor 4, a transmission device 5, a crushing cone mechanism 6 and a crushing chamber control mechanism 7, wherein the crushing chamber control Mechanism 7 includes feed hopper 71, support sleeve 72, adjustment sleeve 73, outer ring gear 74, push cylinder 75, lock ring 76, 16 lock cylinders 77, 8 hydraulic cylinders 78 and 4 jacks 79, push cylinder The number of 75 is two, and the locking cylinder 77 can be a hydraulic locking cylinder or a disc spring locking cylinder.

[0037] In this embodiment, the inner diameter of the support sleeve 72 is equal to the inner diameter of the locking ring 76, and both the support sleeve 72 and the locking ring 76 are provided with internal threads, and the shape and size of the internal threads in the support sleeve 72 are the same as those of the locking ring 76. The ...

Embodiment 2

[0054] see Figure 13 to Figure 15 The large-scale energy-saving and high-efficiency cone crusher in this embodiment includes a frame 1, an upper lining plate 2, a lower lining plate 3, a motor 4, a transmission device 5, a crushing cone mechanism 6 and a crushing chamber control mechanism 7. In this embodiment, Compared with the large energy-saving and high-efficiency cone crusher in Example 1, the large-scale energy-saving and high-efficiency cone crusher differs in the shape of the upper liner 2, the lower liner 3 and the crushing cone 65 in the crushing cone mechanism 6, and other structures are the same The same or similar, will not be described in detail here. If the large-scale energy-saving and high-efficiency cone crusher in this example and the large-scale energy-saving and high-efficiency cone crusher in Example 1 are divided into series, the large-scale energy-saving and high-efficiency cone crusher in this example belongs to the short head series, and in Example 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com