A small negative pressure jet mill with an ellipsoidal structure crushing chamber

A pulverizing cavity and jet mill technology, applied in the field of pulverizing machinery, can solve problems such as difficulty in meeting the requirements of particle pulverization, asymmetric structure of the pulverizing cavity of the jet mill, and uneven size of the pulverized particles, so as to avoid unstable gas flow and structural problems. Symmetrical, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

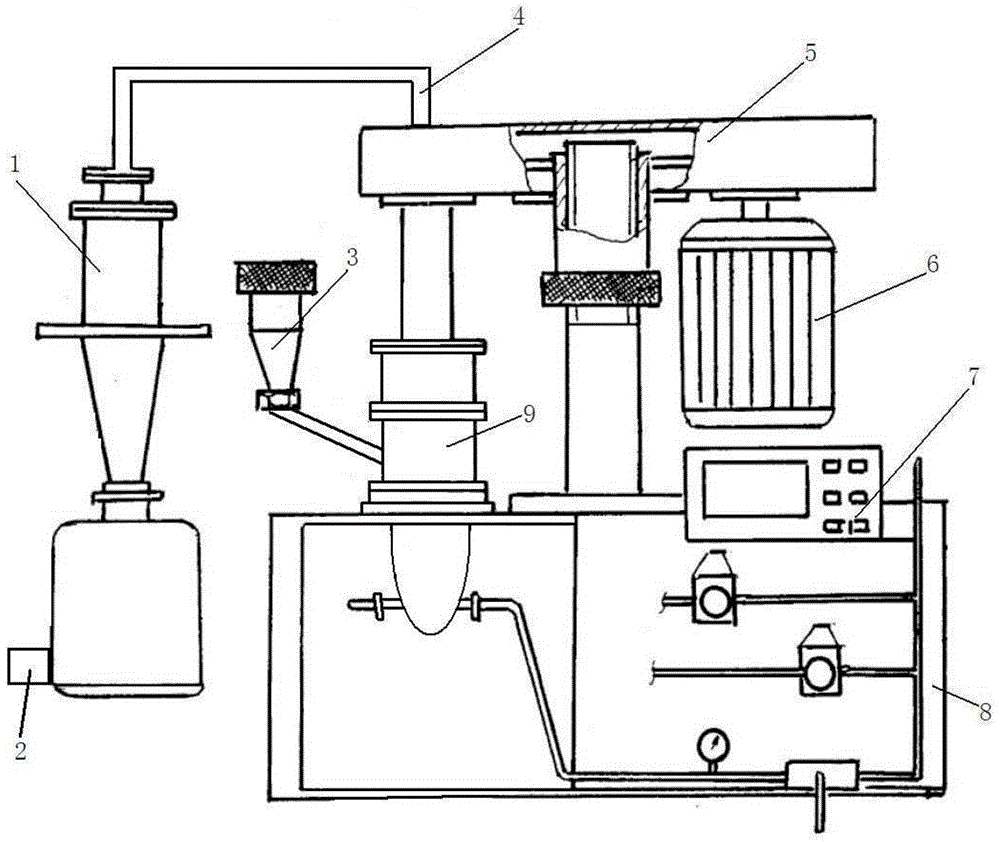

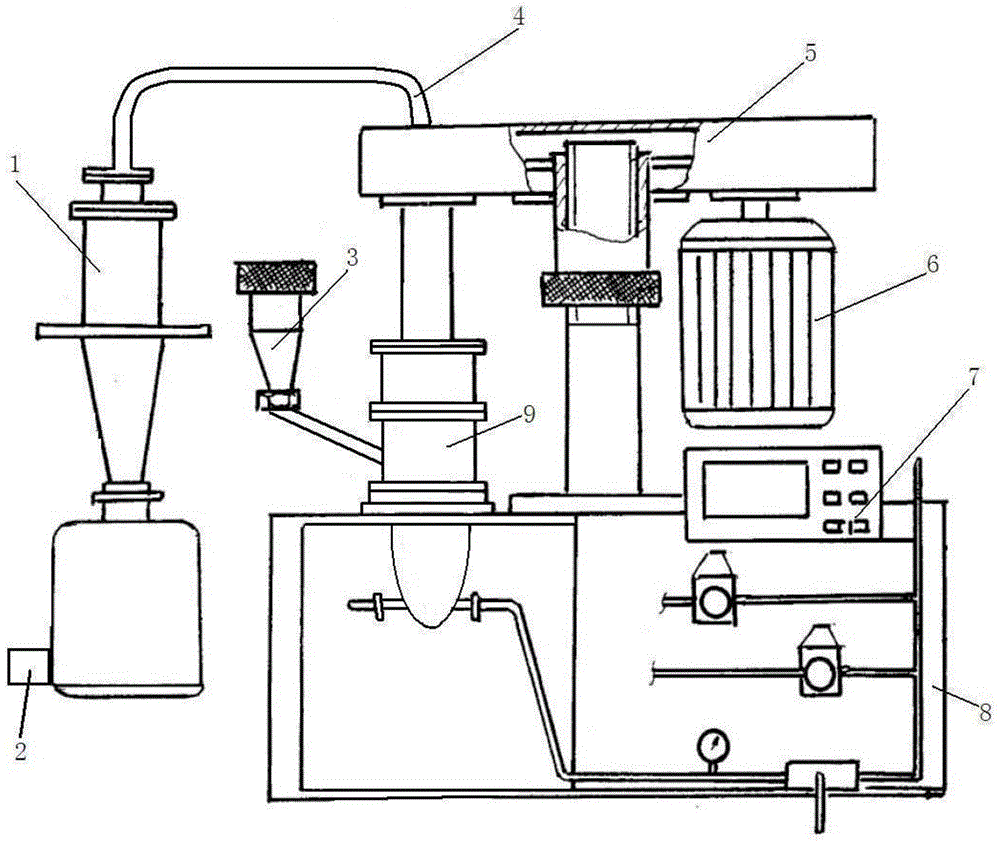

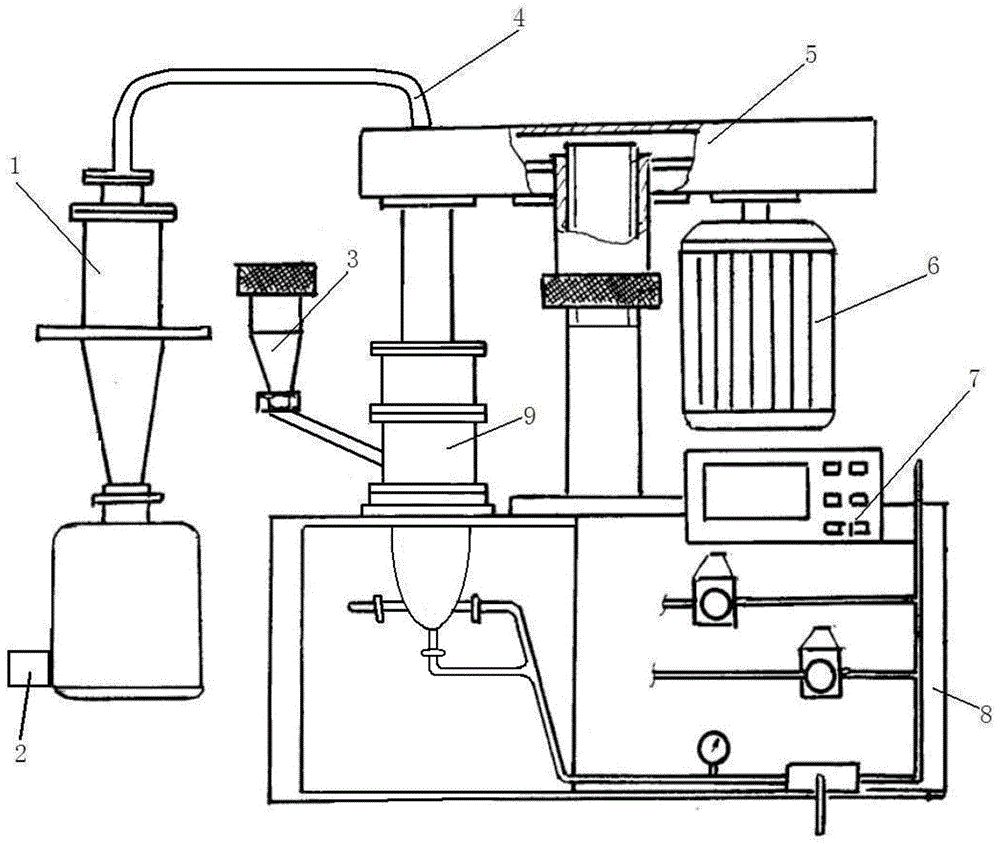

[0057] figure 1 It is a schematic diagram of the overall structure of a small-sized negative pressure jet mill with an ellipsoidal structure in the embodiment of the present invention. It includes a collection device 1, a negative pressure device 2, a feeding device 3, an output pipe 4, a bracket 5, a motor 6, a control mechanism 7, a support 8, and a jet mill 9. The collection device 1 communicates with the jet mill 9 through the output pipe 4 . The feeding device 3 includes at least one hopper, which is connected to the crushing chamber of the jet mill 9 through a pipeline, and a classification mechanism is arranged inside the crushing chamber, and an air inlet pipe is connected to the bottom of the crushing chamber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com