UVLED curing assembly for backlight

A component and reflective technology, which is applied in the field of UVLED curing components for backlights, can solve the problems that UV curing equipment cannot meet the integration requirements of UVLED light source modules, and achieve the effects of fast curing speed, improved cooling efficiency, and increased radiant energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

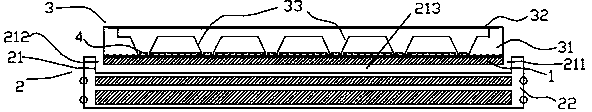

[0028] Such as figure 1 Shown, a kind of UVLED curing assembly for backlight, it includes several UVLED light-emitting units, it also includes:

[0029] A heat dissipation substrate 1, the plurality of UVLED light-emitting units are arranged on the front of the heat dissipation substrate 1;

[0030] A heat dissipation system 2, located on the back of the heat dissipation substrate 1;

[0031] A reflective cover 3, the reflective cover 3 forms a reflective peripheral wall 31 for reflecting the light of the UVLED light-emitting unit on the front of the heat dissipation substrate 1, and the reflective cover forms a light-transmitting plate 32 for the light of the UVLED light-emitting unit to pass through on the top of the reflective peripheral wall 31. The light-transmitting plate 32 is provided with a reflective cup 33 at a corresponding position of each UVLED light-emitting unit for converging light emitted by the UVLED light-emitting unit.

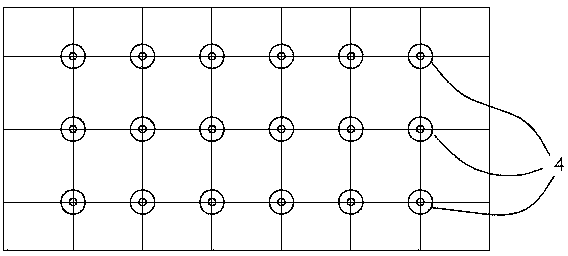

[0032] Such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com