LED chip packaging method and LED lamp bead

A technology of LED chips and LED lamp beads, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inconsistent excitation efficiency and poor uniformity of light emission, and achieve the effect of reducing chromatic aberration, reducing the angle of light output, and uniform light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

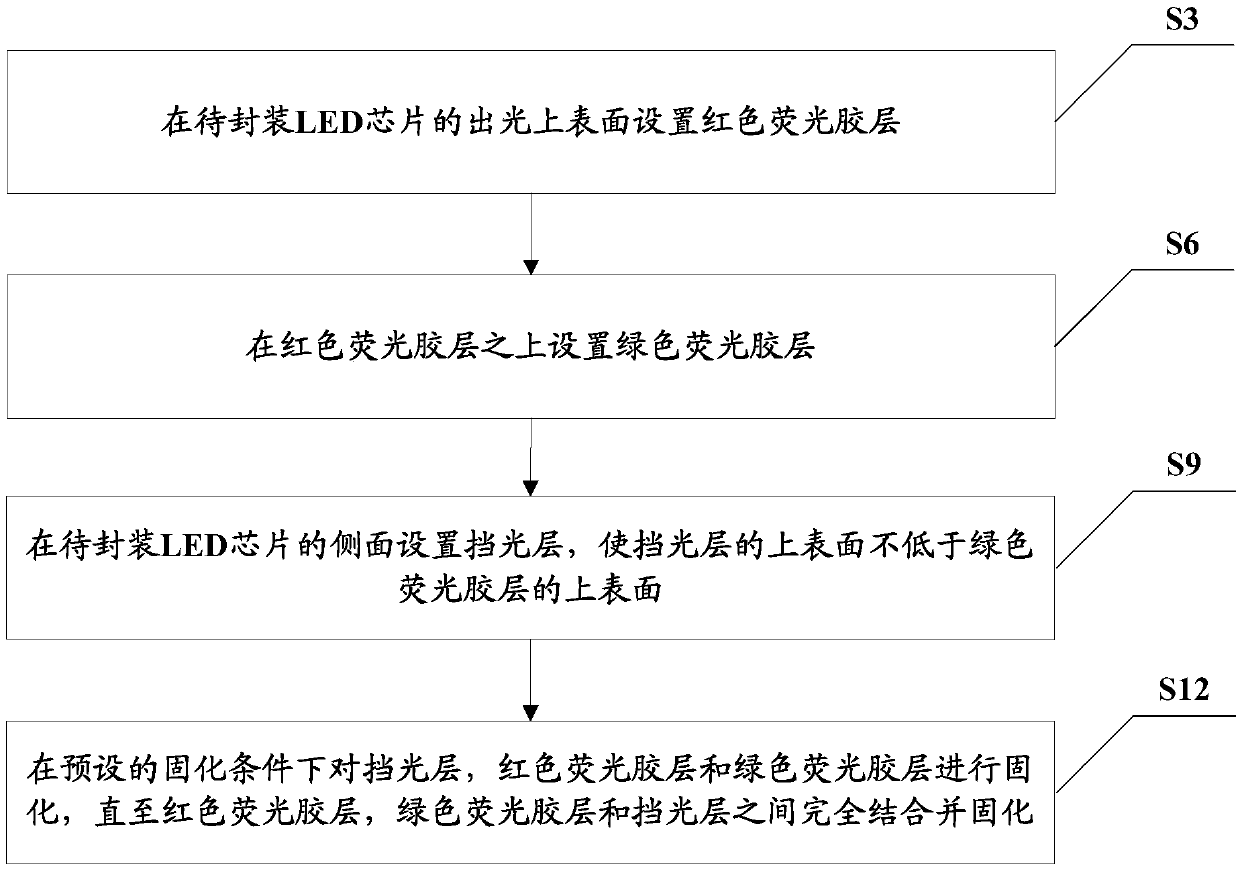

[0054] In order to solve the problem of poor luminous uniformity of LED products due to the installation of a layer of fluorescent adhesive layer mixed with various luminescence conversion media with inconsistent excitation efficiencies in the prior art, this embodiment provides a new LED chip package method, the LED lamp bead prepared by the LED chip encapsulation method emits light uniformly and has high luminous efficiency, please refer to the following image 3 The flow chart of the LED chip packaging method shown:

[0055] S3: setting a red fluorescent adhesive layer on the light emitting upper surface of the LED chip to be packaged.

[0056] S6: setting a green fluorescent glue layer on the red fluorescent glue layer.

[0057] It should be noted that, in some other embodiments, the positions of the red fluorescent glue layer and the green fluorescent glue layer can be interchanged, but preferably, the color segment with a larger wavelength should be set at the bottom, t...

Embodiment 2

[0076] It should be understood that the LED chip packaging method in this embodiment is applicable to the packaging of a single LED chip, and is also suitable for the packaging of LED chips in batches. An implementation process of batch encapsulation is taken as an example to illustrate below. For the encapsulation process see Figure 5 shown, including:

[0077] S501: Arranging at least two LED chips to be packaged on the preparation carrier according to a preset spacing distance.

[0078] Figure 6 It shows a schematic diagram of a preparation state for preparing wafer-level packaged LED lamp beads in batches. In this embodiment, the preparation carrier 62 is an auxiliary device for packaging LED chips 61 to obtain wafer-level packaged LED lamp beads, which is not a wafer-level packaged LED lamp bead. A part of encapsulating LED lamp beads. In an example of this embodiment, a high-temperature-resistant high-temperature film may be selected as the preparation carrier 62 i...

Embodiment 3

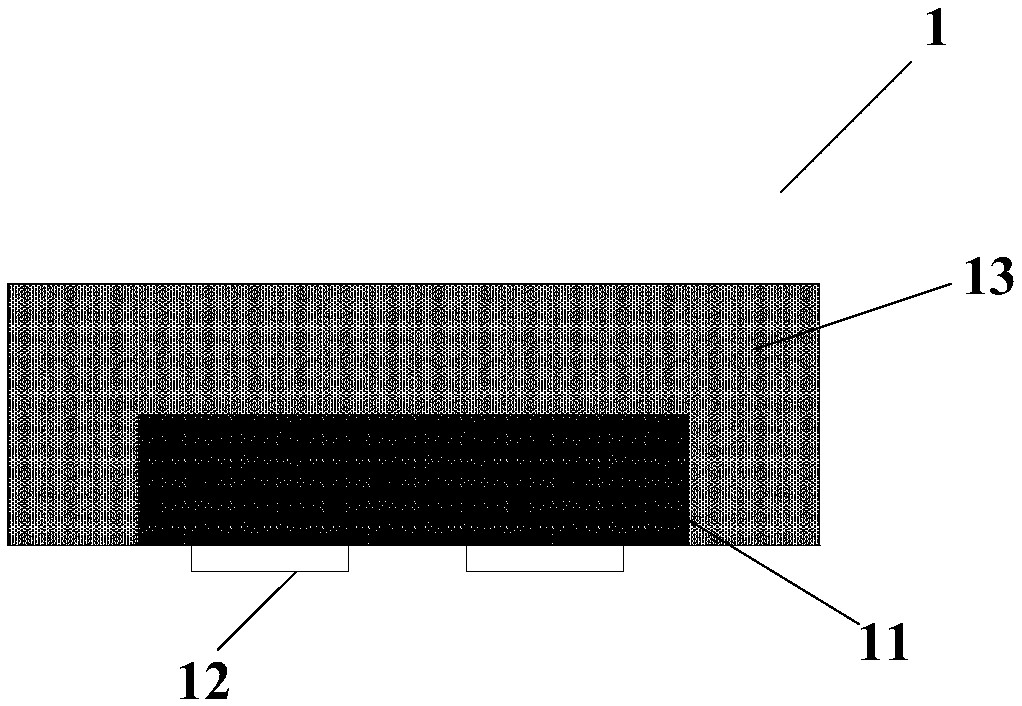

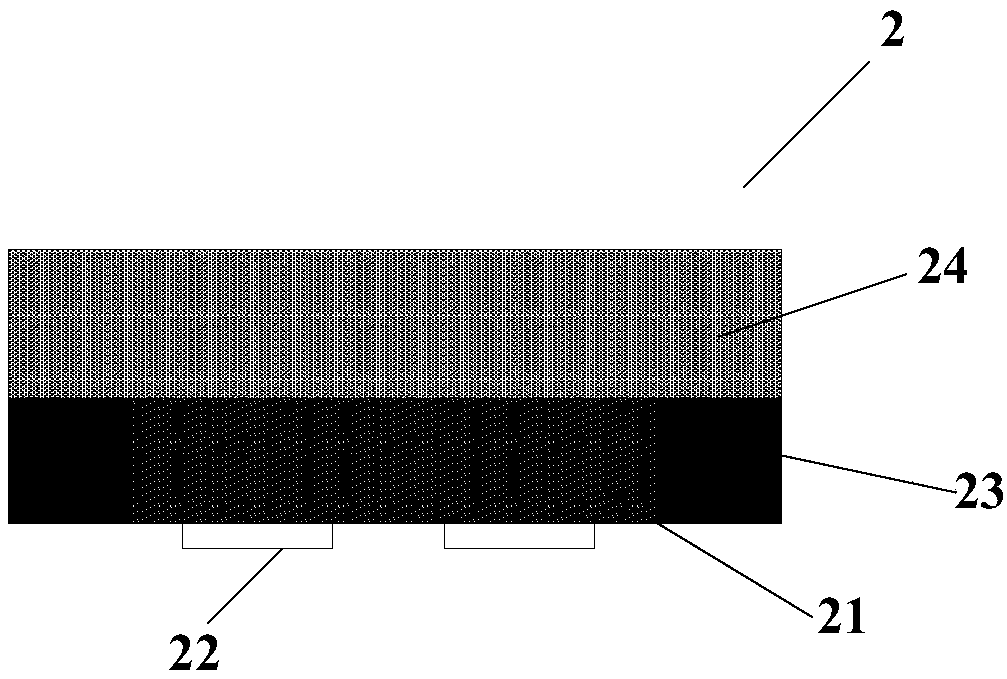

[0107] This embodiment provides an LED lamp bead, please refer to Figure 14 As shown, the LED lamp bead provided in this embodiment includes an LED chip 1401, a red fluorescent adhesive layer 1402, a green fluorescent adhesive layer 1403 and a light blocking layer 1404; wherein, preferably, a nitride red fluorescent adhesive layer can be used in this embodiment And nitride green fluorescent adhesive layer. Of course, in other embodiments, the fluorescent glue layer can also be made of a sulfide system or a silicate system. It should be understood that, in some other embodiments, the above-mentioned red fluorescent glue layer 1402 and green fluorescent glue layer 1403 may be replaced by colloid containing quantum dot photoluminescent material, or other luminescence conversion glue that can realize luminescence conversion. In the embodiment, the red fluorescent adhesive layer 1402 is located on the light emitting upper surface of the LED chip 1401, the green fluorescent adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com