Fully-automatic opening sealing machine of sliding boot plunger component

A fully automatic and closing machine technology, applied in the direction of metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of uneven deformation in the extrusion process, difficulty in controlling the fit gap, and affecting product processing quality, etc., to achieve compact structure, The effect of smooth closing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

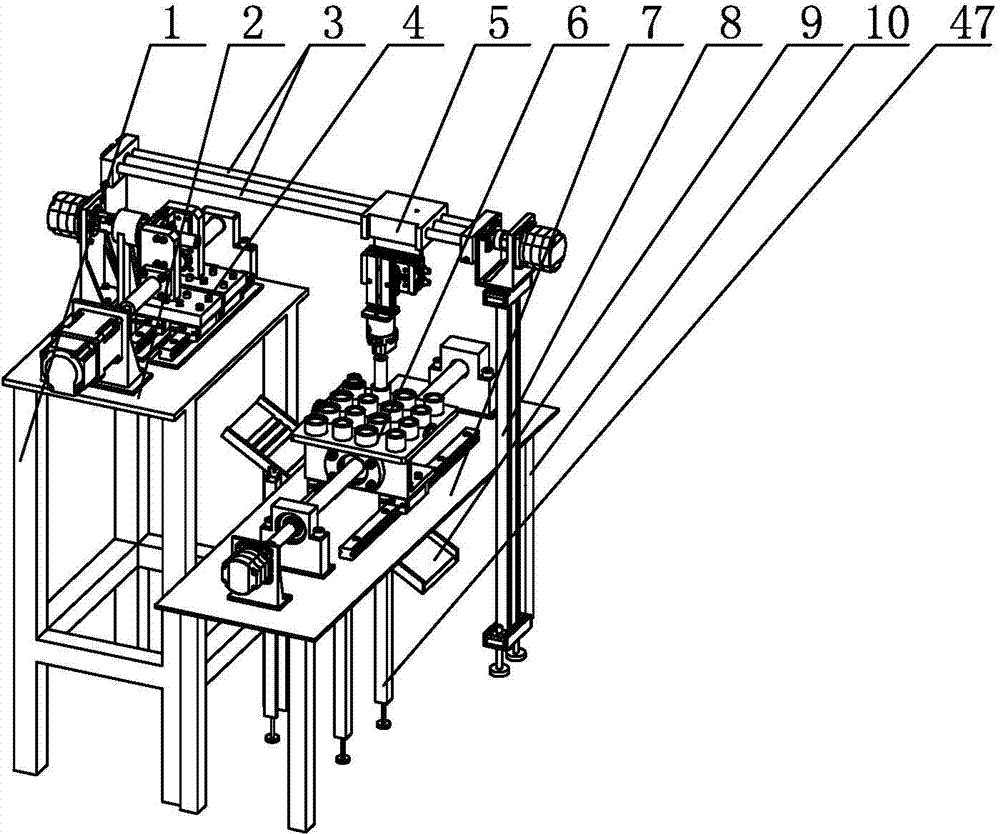

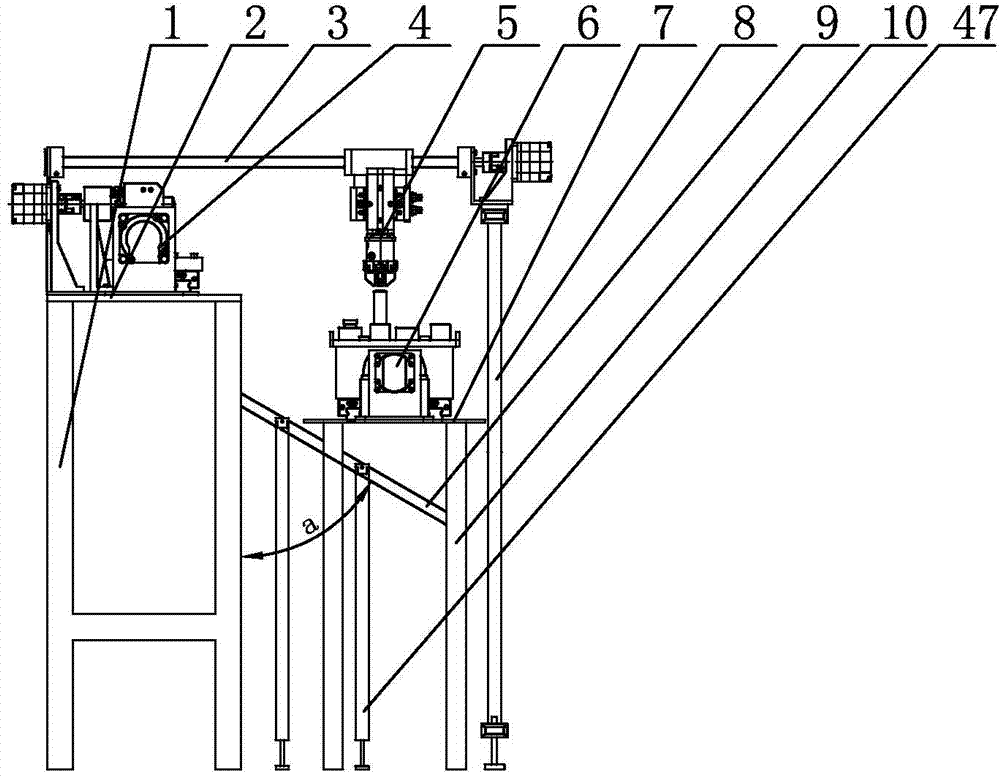

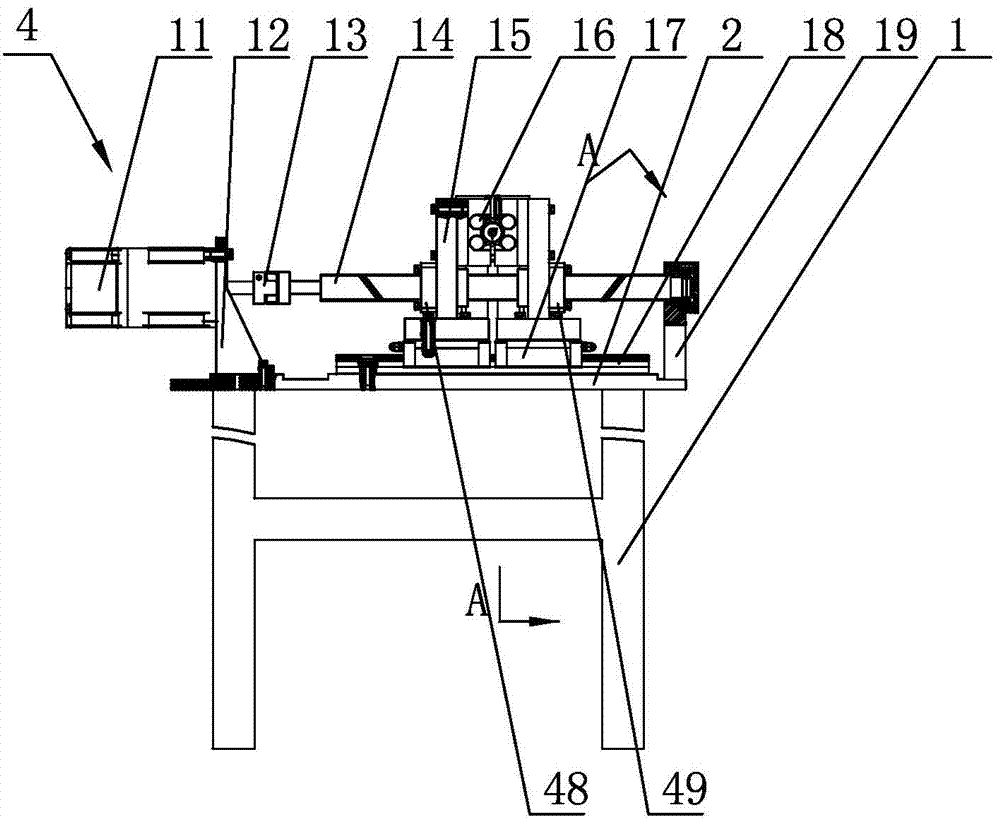

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0035] like figure 1 and figure 2 As shown, the automatic closing machine of the sliding shoe plunger assembly in this embodiment includes a first bed 1, and a rolling mechanism 4 is installed on the first working platform 2 on the first bed 1; One side of the second bed 10 is provided with a second bed 10, and a conveying and loading mechanism 6 is installed on the second working platform 7 of the second bed 10; the side of the second bed 10 is also provided with an adjustable frame 8, which can be The top of the adjustment frame 8 is equipped with a manipulator loading and unloading mechanism 5, which is respectively docked with the conveying and loading mechanism 6 and the rolling mechanism 4; the lower part of the second working platform 7 is provided with a blanking plate 9, and the blanking plate 9 by adjusting the frame 47 to sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com