Process for protecting a component, process for laser drilling and component

A technology for laser drilling and protecting components, which can be used in laser welding equipment, applications, household appliances, etc., and can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

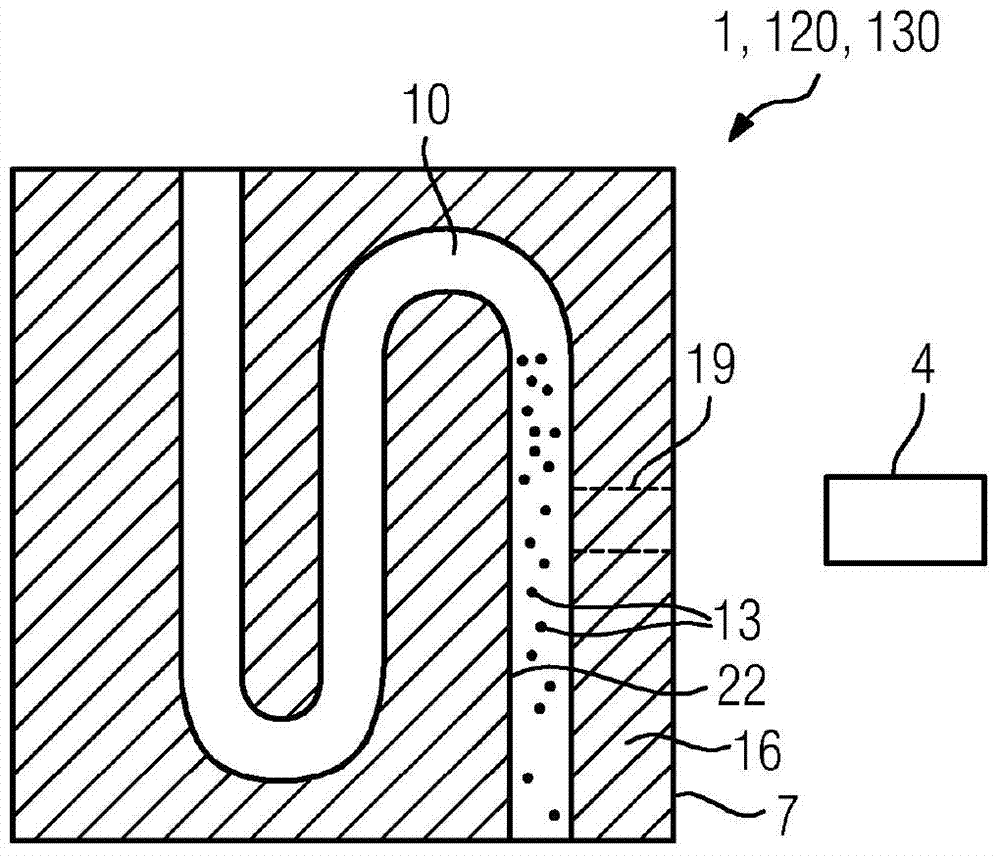

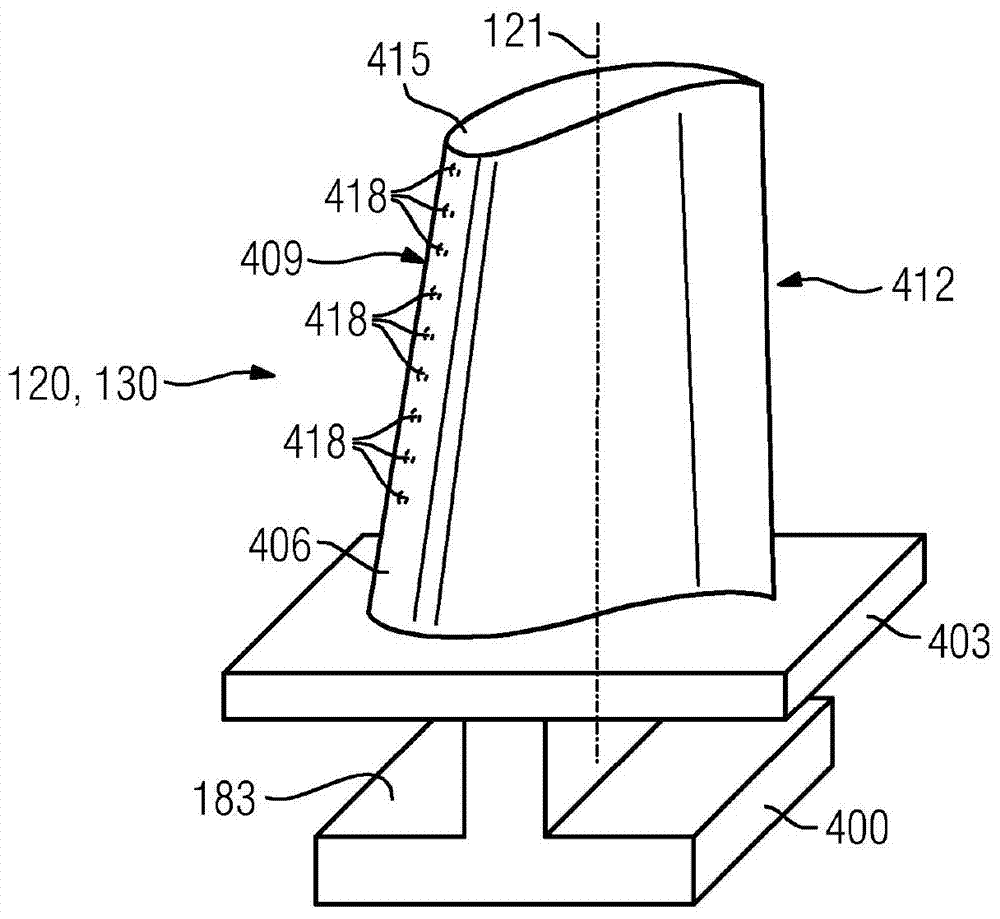

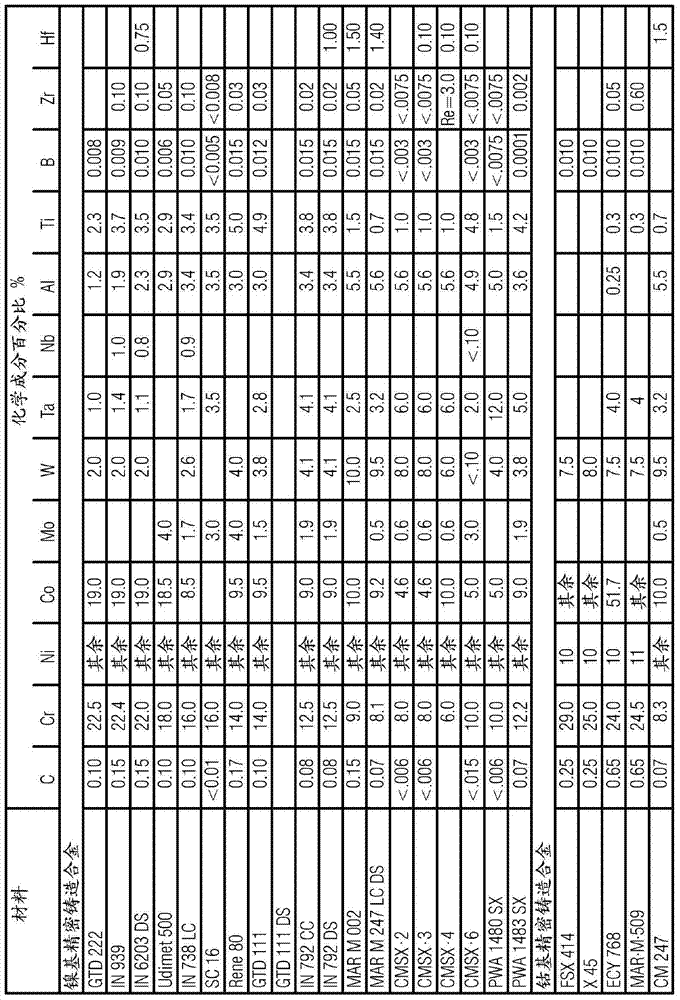

[0013] figure 1 The hollow component 1 shown only as an example is made of a nickel-based or cobalt-based alloy (preferably according to image 3 ) made of turbine blades 120, 130 ( figure 2 ), the hollow member has a cavity 10 . The wall 16 of the hollow space 10 of the component 1 , 120 , 130 is intended to pass through in particular—indicated by dashed lines—in a region 19 a through-opening 19 (described below only by way of example). This is done by means of a laser 4 (or an electron gun), whose beam removes material of the wall 16 from the surface 7 . During penetration into the cavity 10 , the inner structure 22 in the cavity 10 of the hollow component 1 , 120 , 130 can be damaged.

[0014] In order to avoid this, Teflon powder 13 is introduced into cavity 10 at least in the region of through-holes 19 to be produced. Here, Teflon powder 13 is introduced into cavity 10 via a carrier liquid. The above-mentioned carrier liquid is preferably water-based. Here, Teflon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com