Electric tool sharpener

A knife sharpener, electric technology, applied in grinding/polishing equipment, grinding/polishing hand tools, other manufacturing equipment/tools, etc., can solve the problems of reduced work efficiency, inconvenient use, low safety performance, etc. The effect of improving work efficiency, convenient use conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

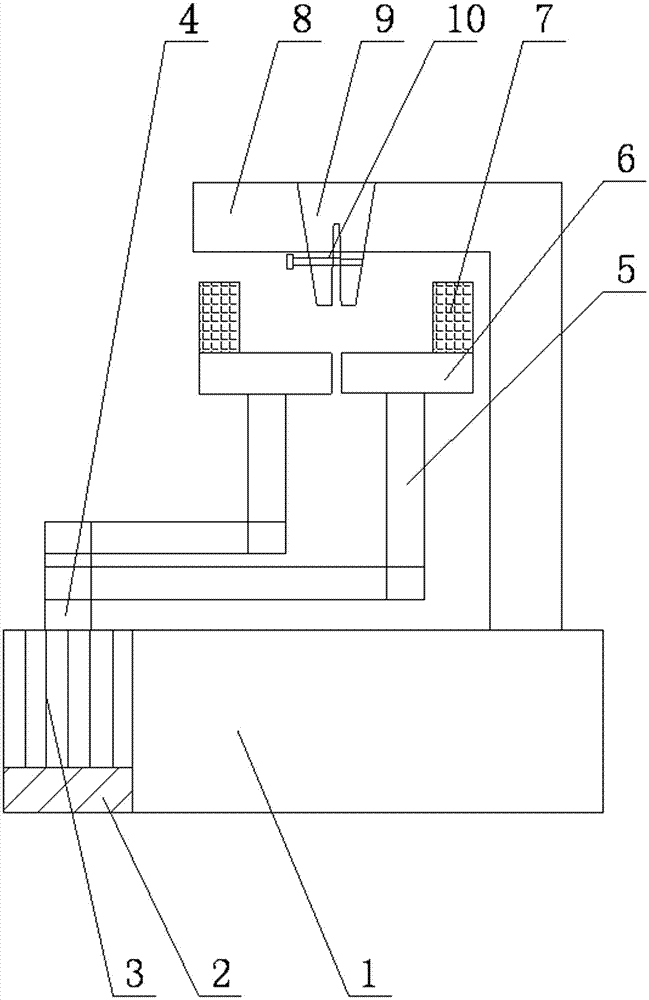

[0014] Such as figure 1 As shown, an electric knife sharpener of the present invention includes a base 1, a motor base 2 is fixed on one side of the base 1, a motor 3 is provided on the motor base 2, and a motor shaft 4 is provided on the motor 3 , the motor shaft 4 is connected to the transmission sharpening group, and the transmission sharpening group includes a transmission shaft 5, an eccentric wheel 6 and a sharpening stone 7, and the motor shaft 4 is connected to the eccentric shaft 6 through the transmission shaft 5, and the eccentric shaft 6 is provided with a whetstone 7, and the base 1 is provided with a bracket 8 away from the side of the motor 3, and a whetstone fixture 9 is fixed on the top of the bracket 8, and the transmission whetstone set is provided with two groups, symmetrically located on the side of the whetstone On both sides of the stone fixture 9, the whetstone fixture 9 is adjusted by the adjustment screw 10, and the motor seat has two rubber buffer pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com