Active safety seat system

A safety and seat technology, applied in movable seats, vehicle seats, special positions of vehicles, etc., can solve problems such as automatic adjustment of mechanical platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

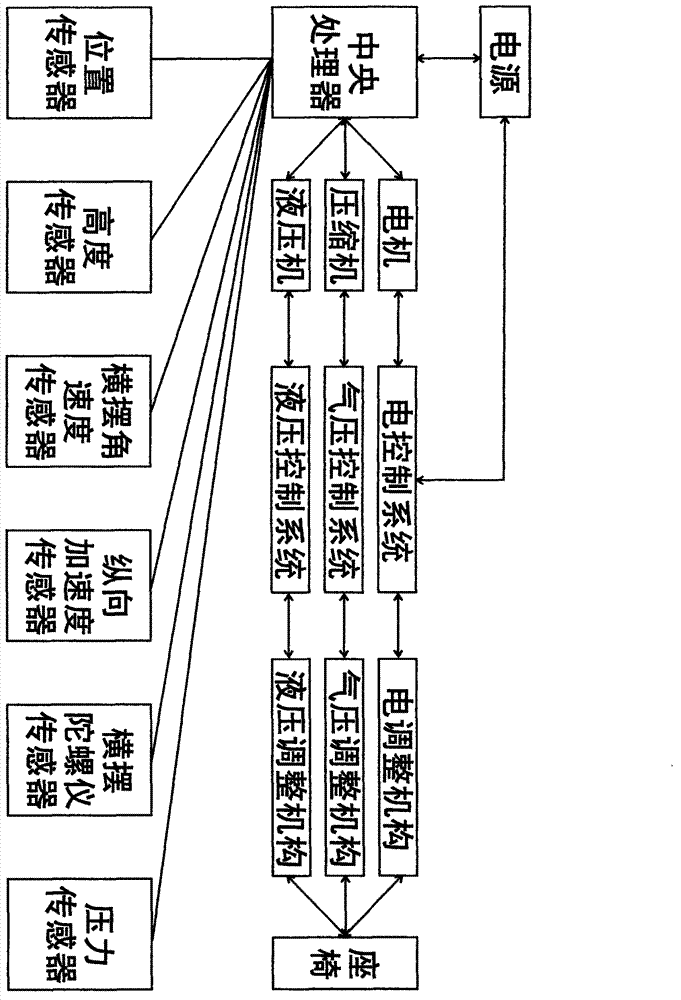

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

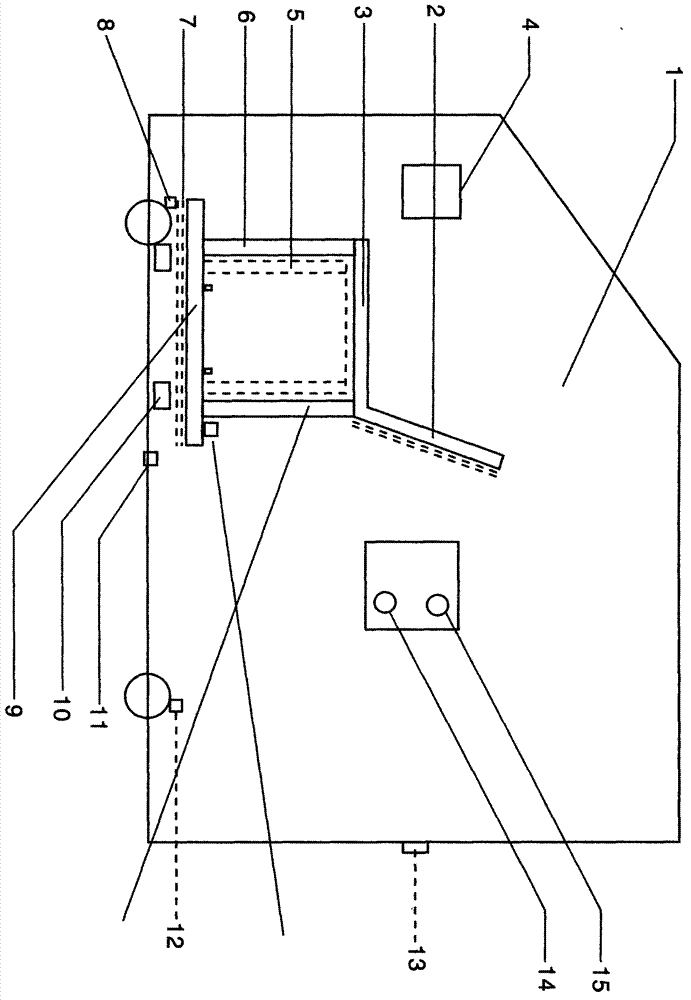

Embodiment Construction

[0021] The present invention is an active safety seat system, which can be appropriately increased or decreased according to reality when applied in different fields. If it is applied to the automotive field, it can have all the features of the present invention, and when it is applied to the aerospace field, it can omit some features, such as only retaining automatic movement to the front or rear, upwards or downwards, and the four supporting points of the seat are independent. The support is relatively independent, and when any side of the mechanical platform is tilted, and when the front or rear of the mechanical platform is raised, the seat remains horizontal as a whole, and moves in the direction of centrifugal force when one side is tilted, such as when the left side is tilted. The whole moves to the right, such as when the right side is tilted, the seat moves to the left as a whole; for example, when the front of the mechanical platform rises, the two supports in front o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com