A centralized control box for a mining belt conveyor

A belt conveyor and centralized control box technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of low integration, inconvenient maintenance and maintenance, and scattered functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

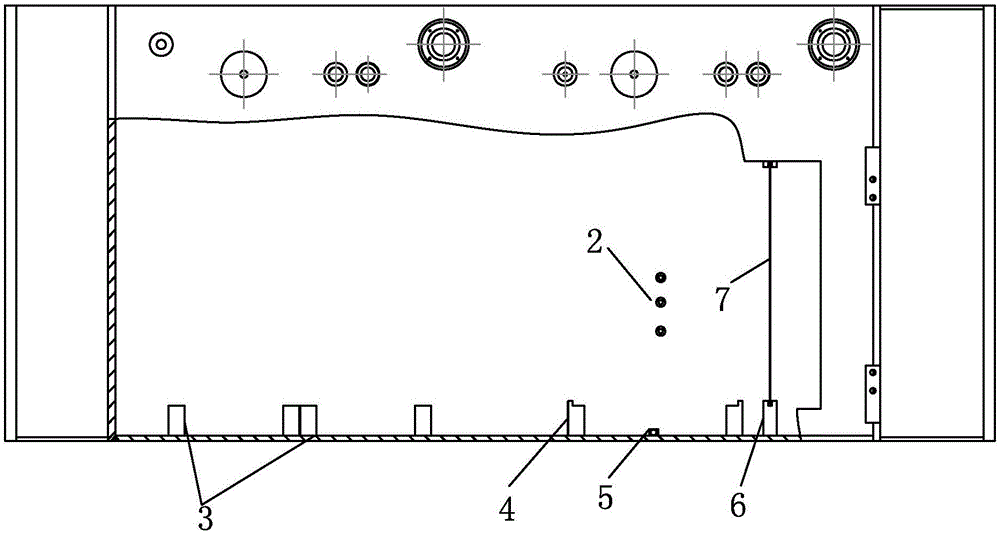

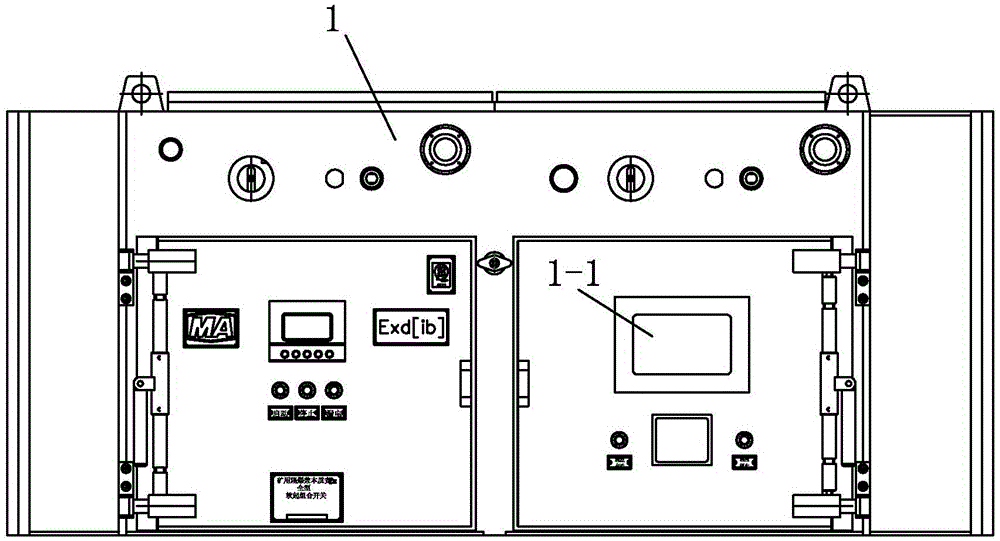

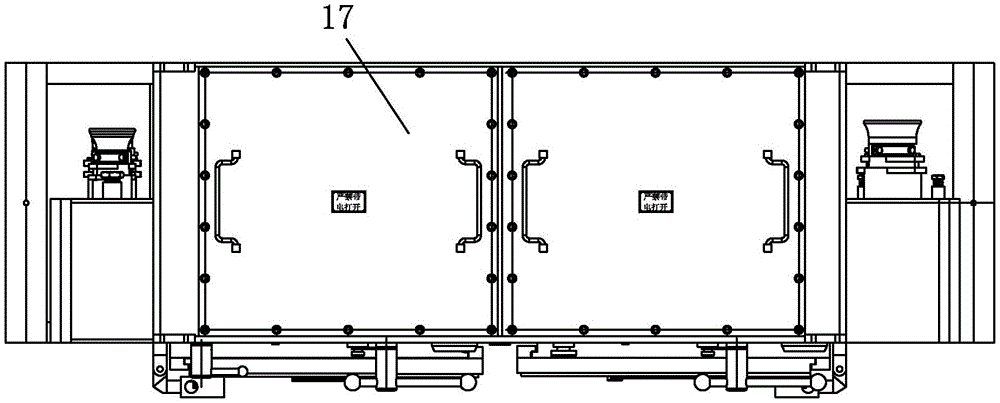

[0017] Such as figure 1 , 2 , 3 and 4, a centralized control box of a mine belt conveyor includes a centralized control box housing, a liquid crystal display 1-1 is arranged on the front panel of the centralized control box housing, and the inside of the centralized control box Two pairs of movement chutes 3 arranged in parallel are arranged on the bottom surface near the left end, a pair of parallel movement tracks 4 are arranged on the right side of the movement chute 3, and a PLC fixed plate chute 6 is arranged on the right side of the movement track 4, Two isolating changeover switches (not shown in the figure), two transformers (not shown in the figure), a lighting panel (not shown in the figure), two soft starters 13, a core 19. A PLC fixed plate 7, the soft starting core 13 is installed in the central control box housing through the core chute 3, the core 19 is installed in the central control box shell through the core track 4, the PLC The control board is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com