3cr2mnmos mold steel refining denaturant adding method

A technology of die steel and denaturant, applied in the direction of improving process efficiency, can solve the problems of low yield of denaturant, low spheroidization rate of inclusions, unstable denaturation effect, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

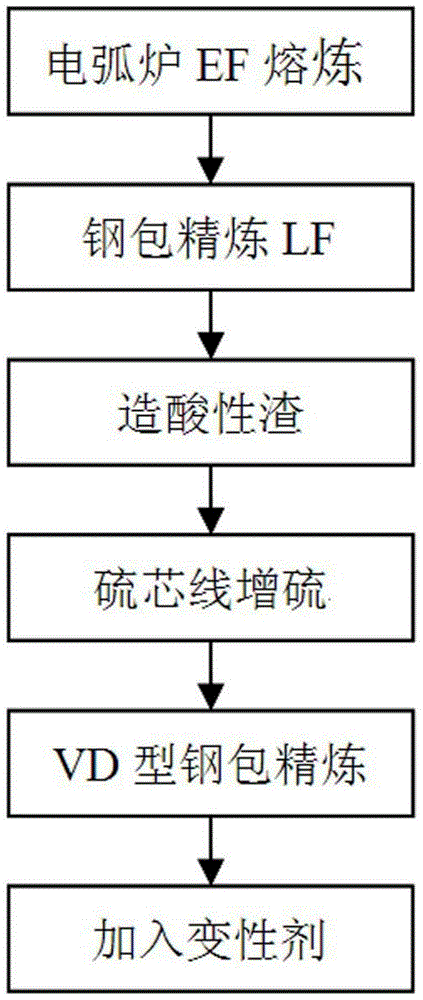

Method used

Image

Examples

Embodiment 1

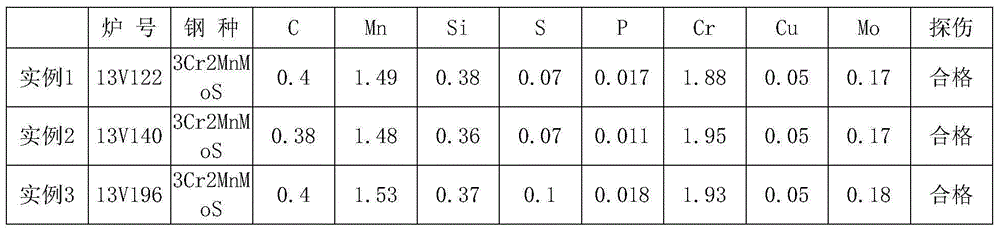

[0032] Furnace number 13V122, steel type 3Cr2MnMoS, ingot shape 10.6T, count 2;

[0033] Electric arc furnace EF smelting, oxygen blowing and fluxing, oxygen pressure 0.4Mpa; deep oxygen blowing, oxygen pressure 1.0Mpa; sampling, slag removal 90%, steel tapping temperature 1635°C, molten steel composition weight percentage C0.06, Si0.01, Mn0.06, P0.006, S0.1, Cr0.25, Mo0.15;

[0034] Ladle refining LF, adding 300kg of lime, 650kg of high-carbon ferrochrome, 450kg of high-carbon ferromanganese, and 30kg of ferromolybdenum. After smelting for 30 minutes, feed 80m of aluminum wire, add 30kg of silicon-calcium powder, and 30kg of carbon powder. Sampling and composition of molten steel Weight percent C0.31, Si0.15, Mn1.25. P0.013, S0.045, Cr1.65, Mo0.21;

[0035] To make acid slag, add 400kg of firebricks, the slag alkalinity is 1.1 to 1.4, and the composition of the firebricks is SiO with a weight ratio of 60%. 2 and 40% Al 2 o 3 ;

[0036] Add sulfur to the sulfur core wire...

Embodiment 2

[0040] Furnace number 13V140, steel type 3Cr2MnMoS, ingot type 13T, number of counts 2; the production steps of Example 2 are the same as Example 1, the addition of raw and auxiliary materials, condition control and composition control are also the same as Example 1, the only difference is that The amount of rare earth wire added is slightly different. Because the ingot type 13T of embodiment 2, therefore, the addition amount of rare earth silk is every ingot type 5.5kg.

Embodiment 3

[0042] Furnace number 13V196, steel type 3Cr2MnMoS, ingot type 13T, count 2; Example 3 is actually a repeat test of Example 2, and its production steps, raw and auxiliary materials addition, condition control and composition control are all the same as Example 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com