Automatic sewing device and sewing method thereof

An automatic car and sewing technology, applied in the field of sewing, can solve the problems of high skill requirements for workers, lowering the quality of clothing, and cumbersome technological processes, and achieves the effects of reducing labor, saving time, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

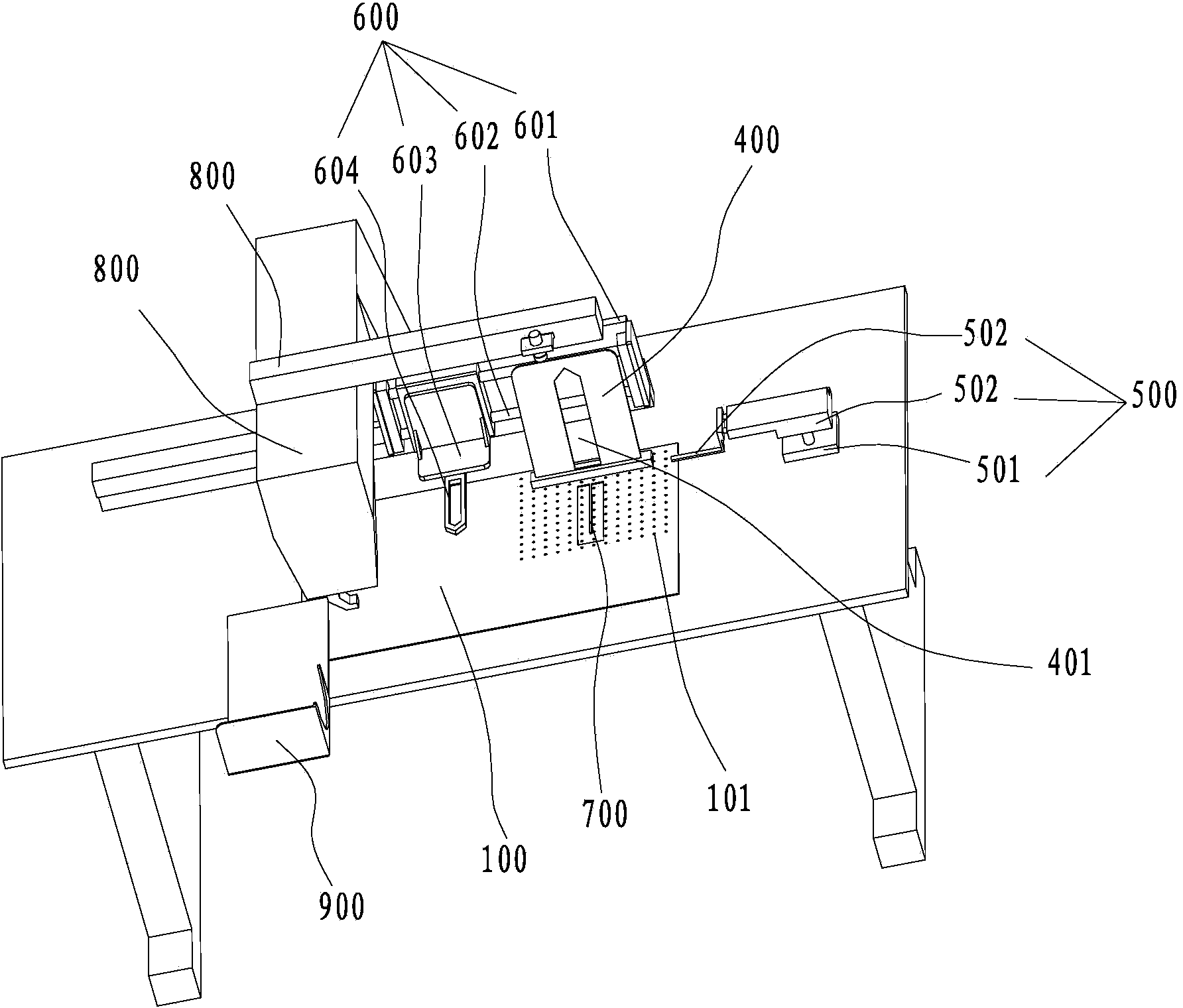

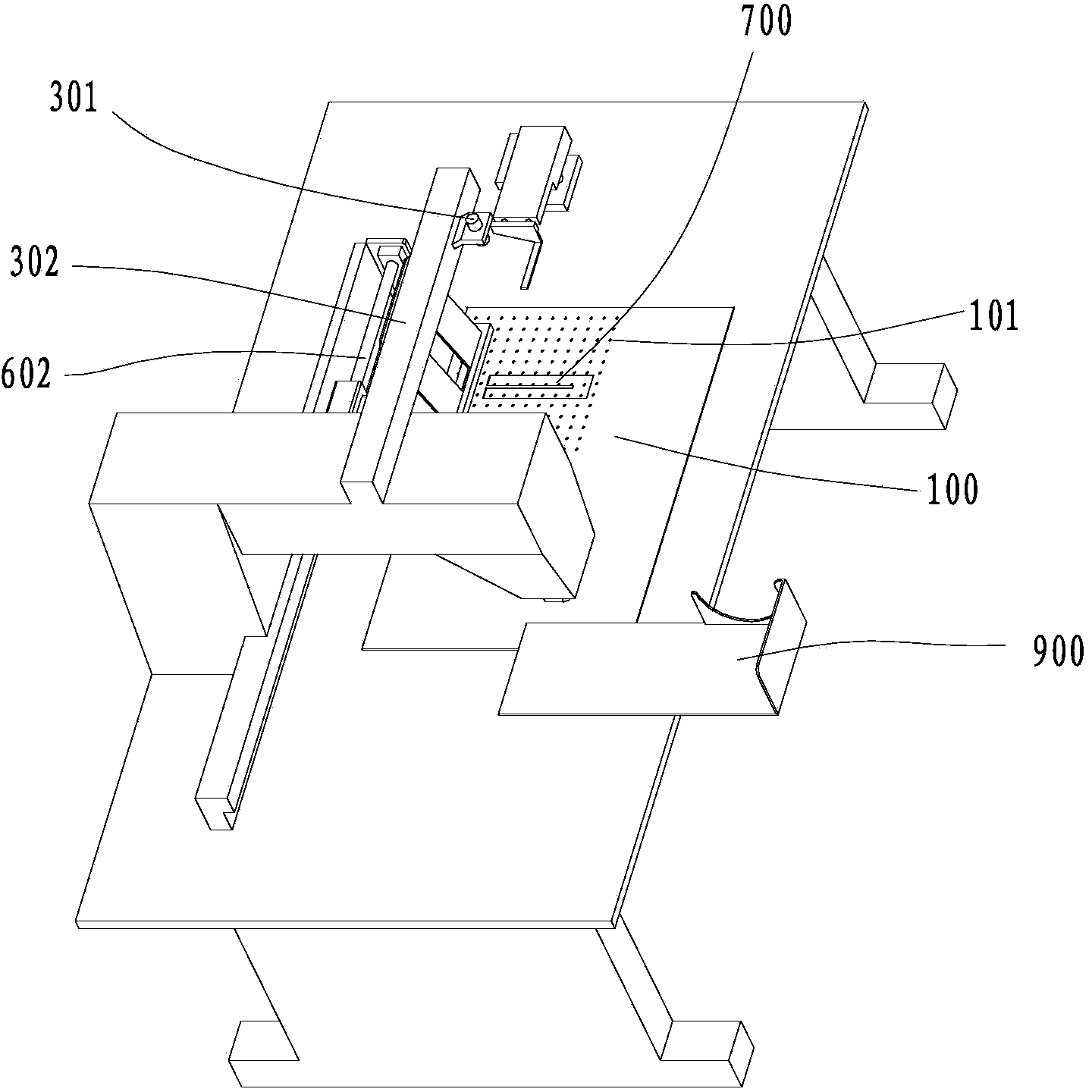

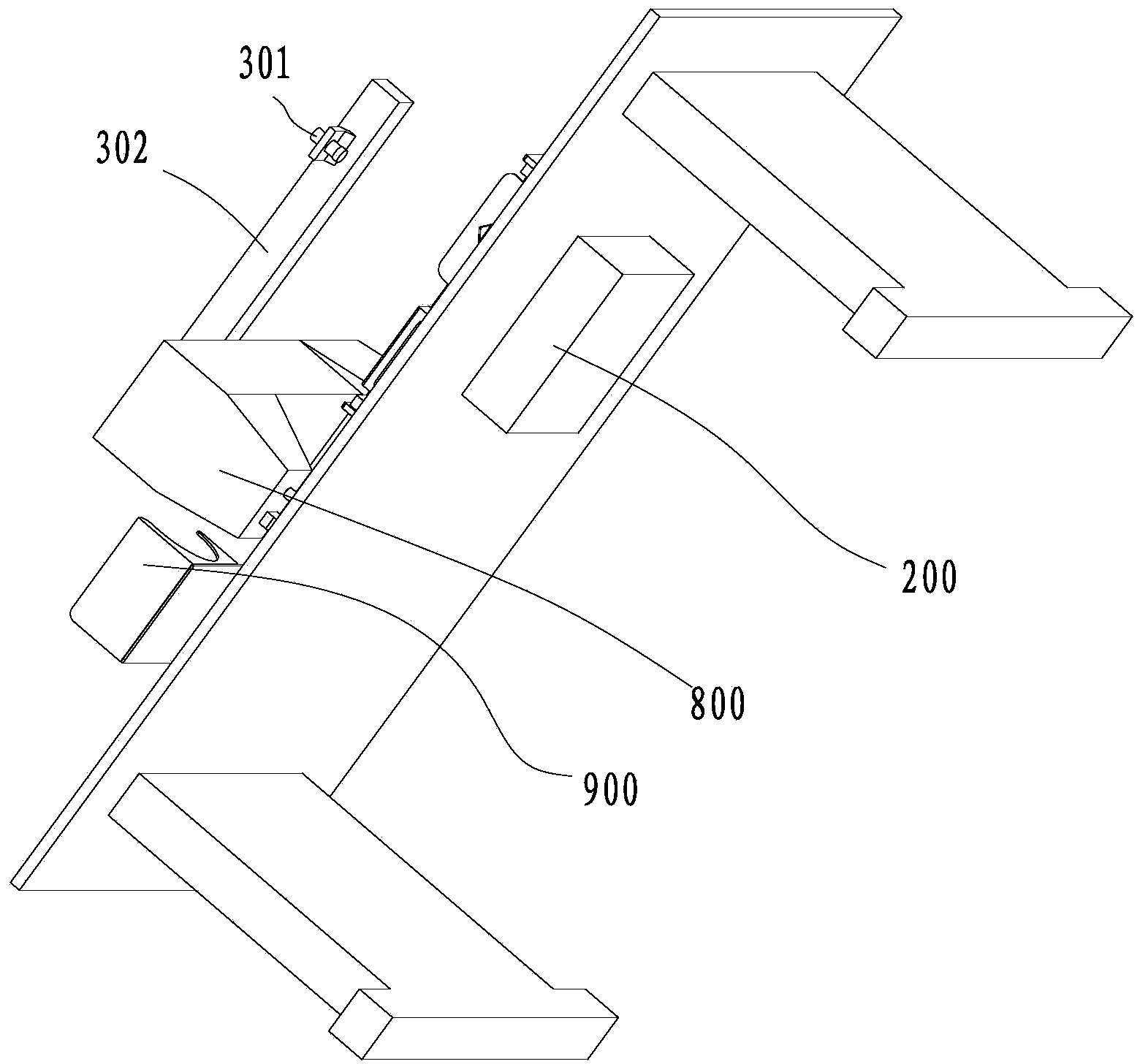

[0041] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0042] Such as Figure 1-3 As shown, in an embodiment of the present invention, an automatic sewing device includes:

[0043] Workbench 100 for placing cloth or webbing;

[0044] The air suction device 200 is used to adsorb the cloth on the workbench 100;

[0045] The positioning device 300 is used for positioning when placing the cloth;

[0046] Pound plate 400, used to suppress the placed cloth;

[0047] Stretching device 500, used for pressing the webbing and unfolding the webbing;

[0048] The presser foot device 600 is used to position the webbing on the fabric as required;

[0049] control device;

[0050]There is a tuyere 101 on the workbench 100, and the air suction device 200 is set at the tuyere 101. The control device is electrically connected with the air suction device 200, the extension device 500, and the presser foot device 600. The scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com