Pneumatic brush head

A brush head, pneumatic technology, applied in the direction of road cleaning, construction, cleaning methods, etc., can solve the problems of reducing the air suction volume of the turbine, polluting the surrounding environment, hindering the entry of dust or garbage, and achieving the effect of reducing power, saving energy and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

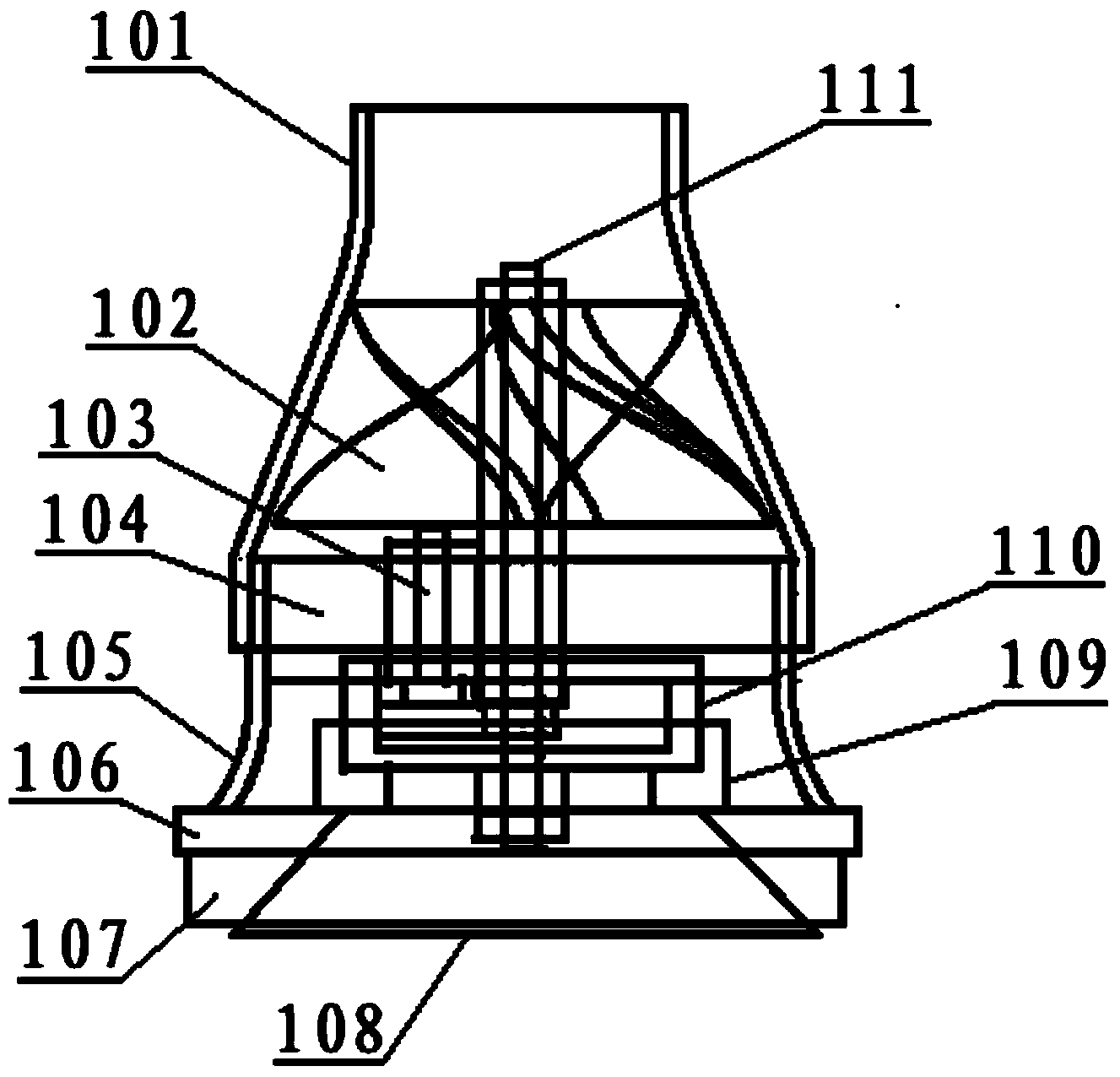

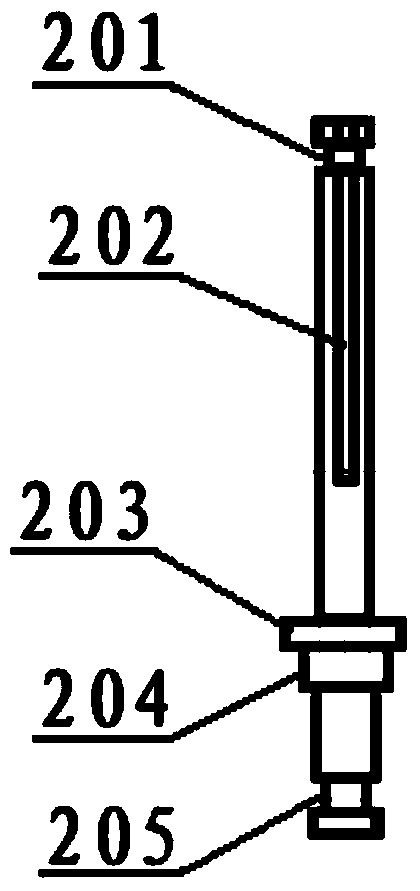

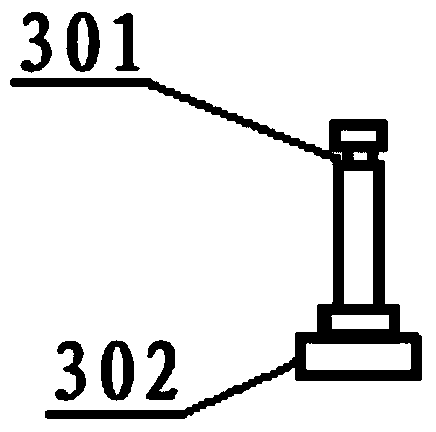

[0036] Such as Figure 1 to Figure 9 Shown is a pneumatic brush head provided by this embodiment, including a negative pressure chamber and a cleaning chamber; a turbine 102 is arranged in the negative pressure chamber; the turbine 102 is rotatably connected to the power unit; Connect the air outlet of the dust collection device; there is a brush roller in the cleaning chamber; the brush roller is rotatably connected with the power unit; the cleaning chamber is provided with an air suction port for absorbing ground dust and an air exhaust port for communicating with the air inlet; The air duct formed by the exhaust port passes through the brush roller.

[0037] Compared with the wind-driven brush head in the prior art, the wind-driven brush head provided by the embodiment of the present invention has the turbine and the brush roller of the wind-driven brush head powered by the same set of power devices, so the turbine and the brush roller can work together . If the power pro...

Embodiment 2

[0052] Such as Figure 10 to Figure 17 Shown is another pneumatic brush head provided in this embodiment, including a negative pressure chamber 1006 and a cleaning chamber 1003; a turbine 1007 is arranged in the negative pressure chamber 1006; the turbine 1007 is rotatably connected with the power device; The air inlet and the air outlet 1008 for connecting the dust suction device; the cleaning chamber 1003 is provided with a brush roller 1002; the brush roller 1002 is rotatably connected with the power unit; the cleaning chamber 1003 is provided with an air suction port 1001 for absorbing ground dust and for The air outlet connected to the air inlet; the air channel formed by the air suction port 1001 and the air outlet passes through the brush roller 1002 .

[0053] Compared with the wind-driven brush head in the prior art, the wind-driven brush head provided by the embodiment of the present invention has the turbine and the brush roller of the wind-driven brush head powered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com