Method of mounting ballast tank in immersed tube

An installation method and a technology for carrying a water tank are applied in the field of floating construction of subsea immersed tube tunnels, which can solve the problems of installation efficiency and effect affecting the efficiency of immersed tube floating construction, narrow space, etc., so as to improve installation efficiency and effect, and achieve orderly Installation, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

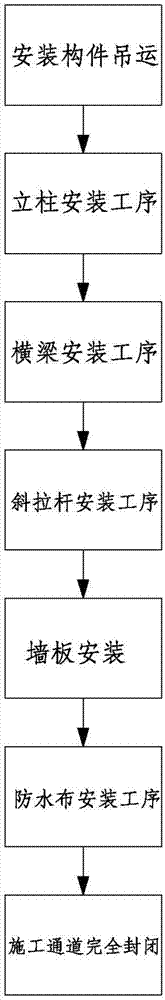

[0055] see figure 1 As shown, the installation method of the ballast water tank in the immersed tube of the present embodiment may further comprise the steps:

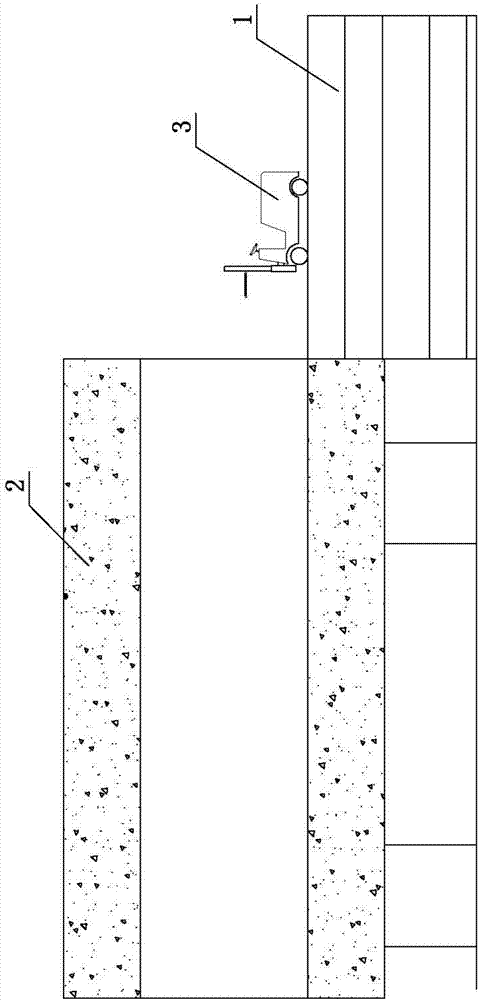

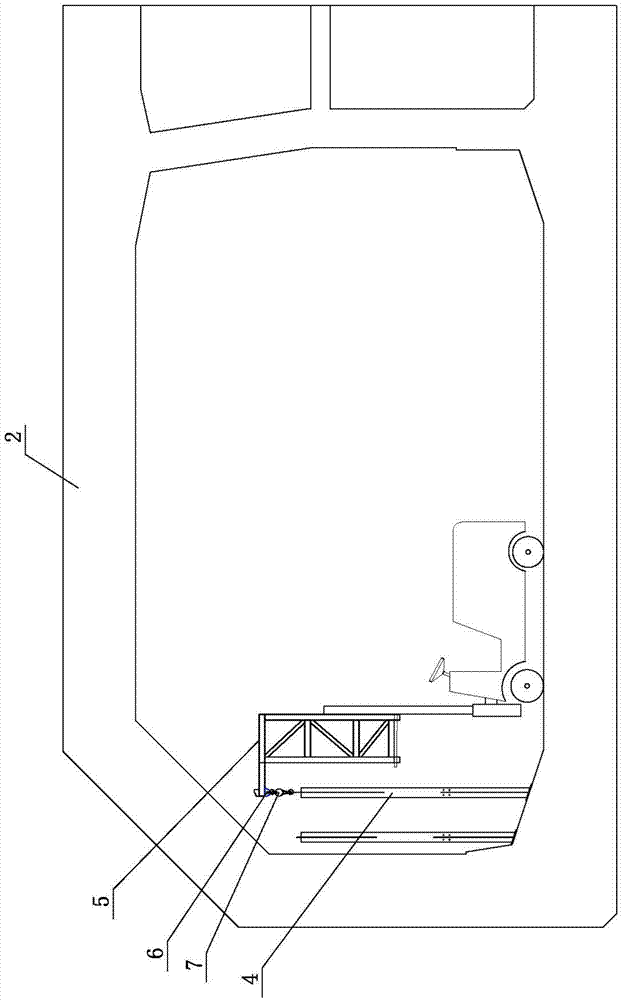

[0056] 1. See figure 2 As shown in the figure, the installation components required for installing the ballast water tank, such as columns, beams, diagonal stays, wall panels and waterproof cloth, are hoisted to the material receiving platform 1 outside the immersed tube by a tower crane; before installation, the ballast water tank Clean up the sundries within the construction scope, then retest the plane position and flatness of each installation station according to the design drawings, mark the installation control boundary, and make corresponding adjustments to each installation station according to the actual deviation and the deviation treatment plan. The installation station described in this embodiment mainly includes a column installation station, a beam installation station and a diagonal rod installation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com