Quick installation structure and installation method of faucet sleeve

A technology of installation structure and sleeve, applied in water supply installations, indoor sanitary piping installations, buildings, etc., can solve problems such as inconvenient installation, and achieve the effects of convenient installation, simple and compact structure, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

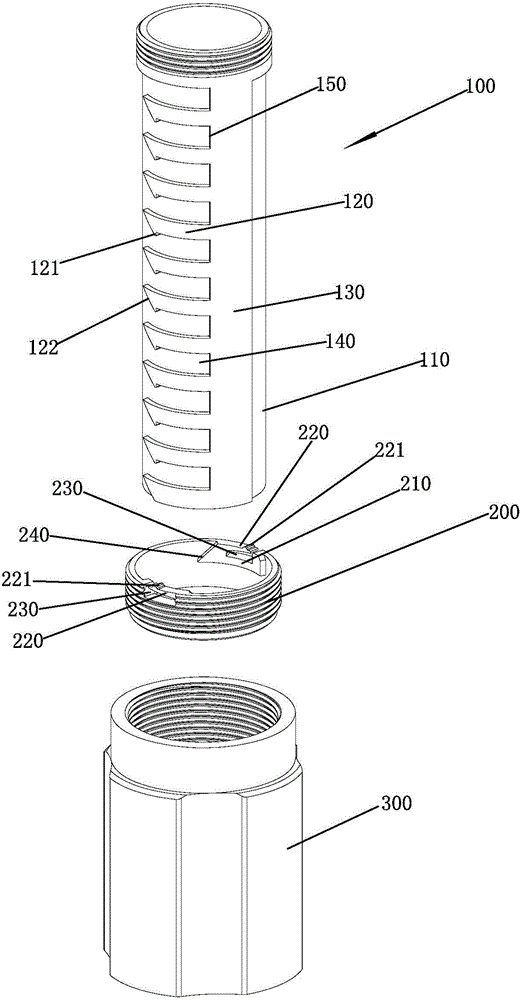

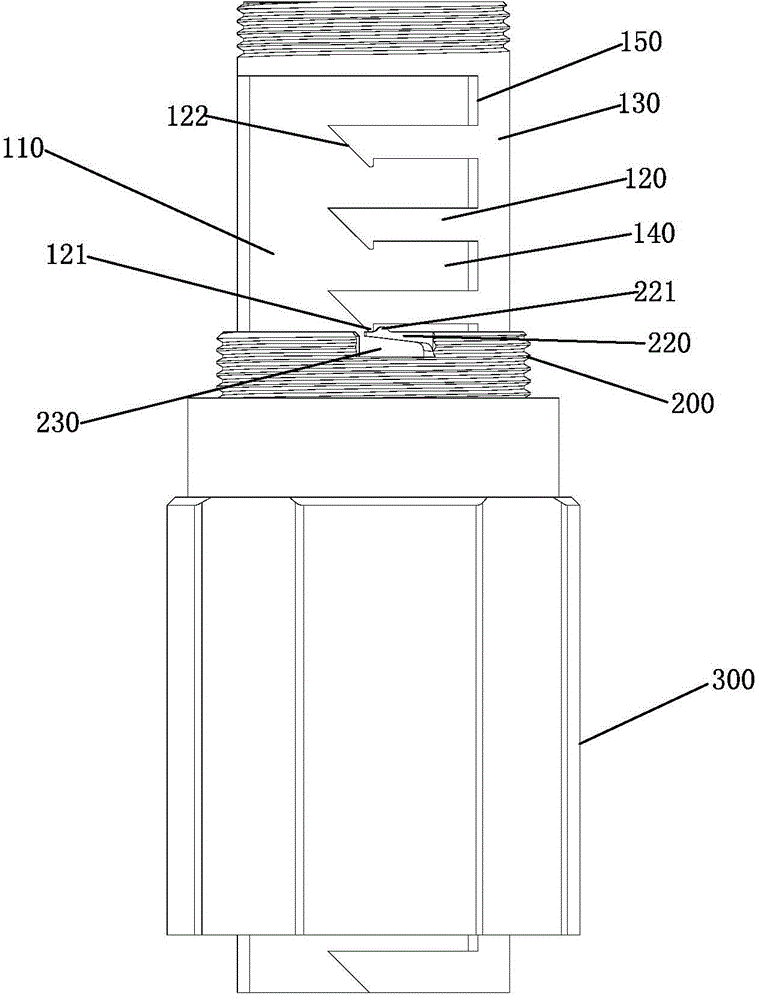

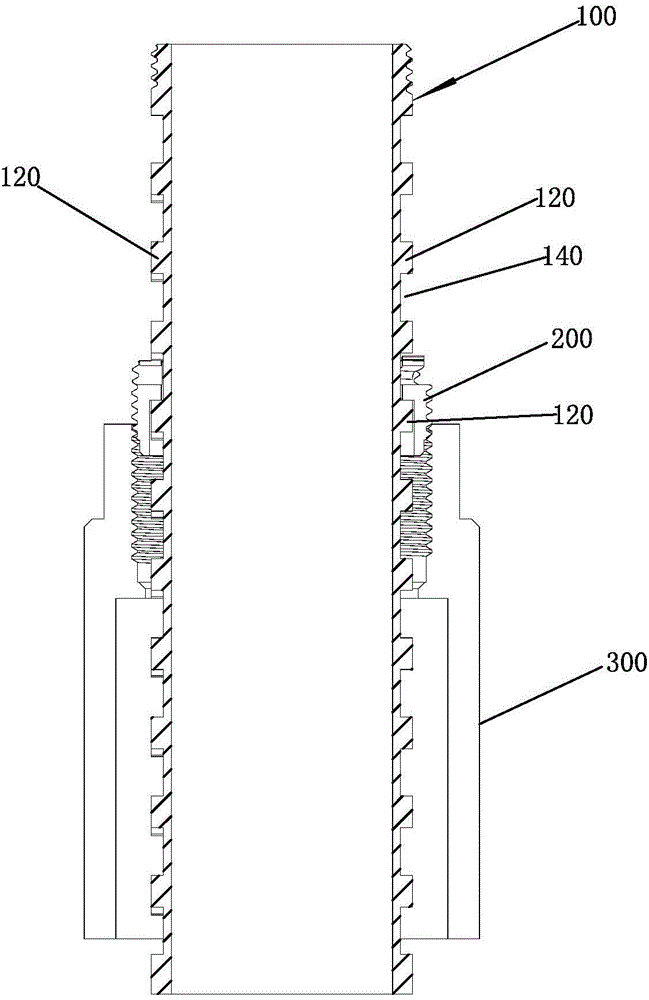

[0032] Please check Figure 1 to Figure 7 , a preferred embodiment of the quick installation structure of the faucet sleeve, the quick installation structure of the faucet sleeve includes a sleeve body 100 , a sliding nut 200 and a locking nut 300 .

[0033] The sleeve body 100 can be detachably attached to the bottom of the faucet or the table top. In this embodiment, the top end of the sleeve body 100 is provided with external threads, and the bottom of the faucet or the table is provided with a screw hole 10 with internal threads, and the sleeve body 100 can be separated from the bottom of the faucet through the screw connection of the internal and external threads. ground connection. The length of the outer thread of the sleeve body 100 is shorter than that of the prior art.

[0034] In this embodiment, at least one sliding groove 110 extending along the length direction of the sleeve body 100 is provided on the outer periphery of the sleeve body 100 . In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com