Method for determining thickness of safety top plate in down-traversing gob by tunnel

A goaf and tunnel technology, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problem of small thickness of the safety roof, and achieve the effect of avoiding too small thickness and reducing construction risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

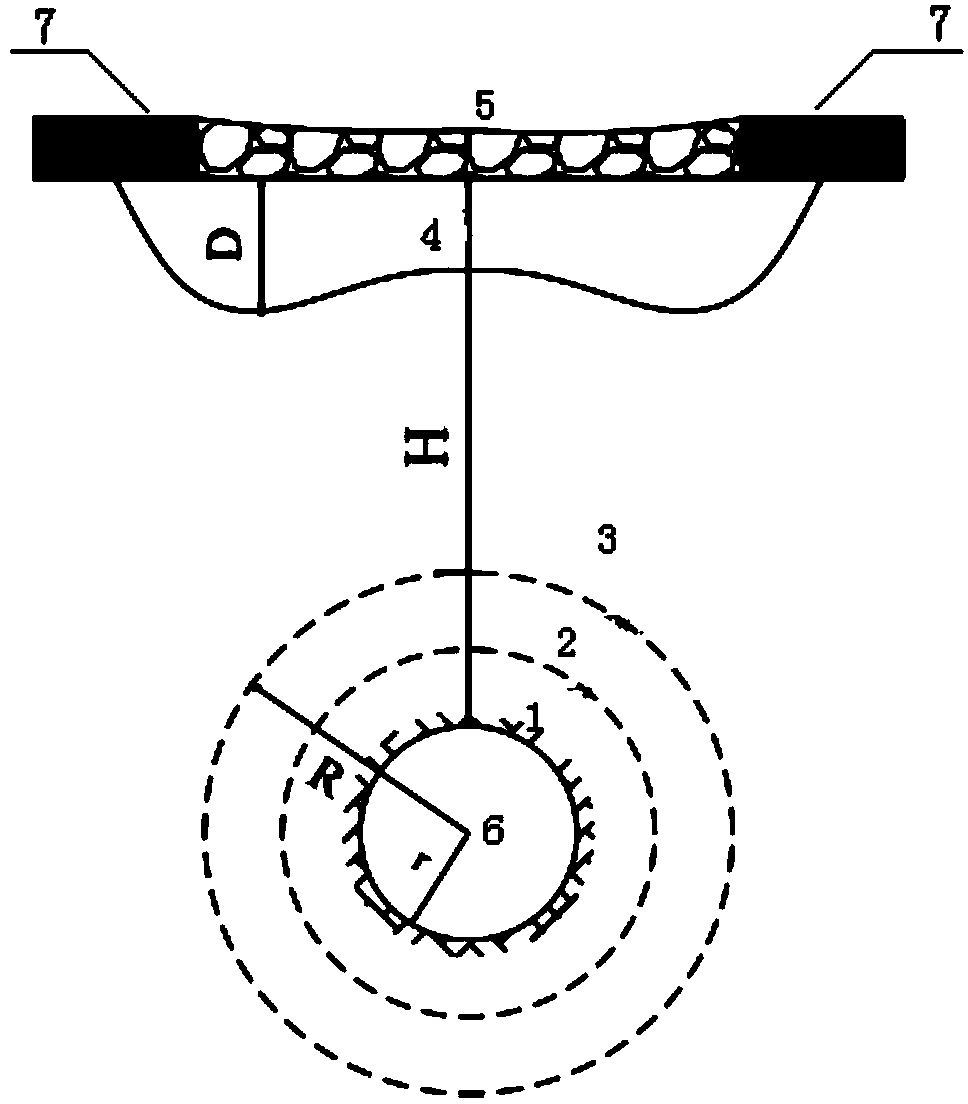

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

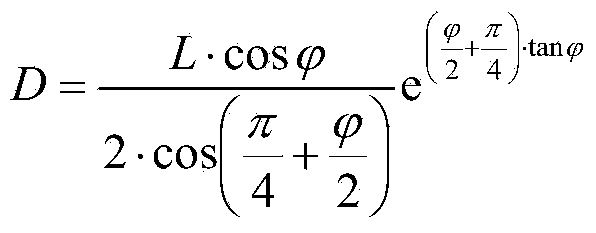

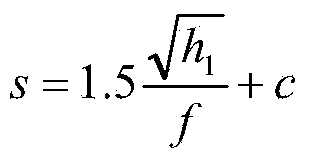

[0016] The main factors affecting the thickness of the safe roof of the tunnel under the goaf are the surrounding rock conditions, the state of the goaf (size, shape of the gob, management method of the gob roof), tunnel construction method, support method, blasting vibration, etc. These factors affect the stability of the thickness of the safety roof, which in turn has an important impact on the stability of the surrounding rock of the tunnel passing through. For the engineering design of the tunnel passing through the goaf, the reasonable thickness of the safety roof can be estimated by using the multi-factor theoretical analysis method.

[0017] Therefore, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com