Large automatic stored ice delivery system and delivery method

A conveying system and automatic technology, applied in ice manufacturing, ice storage/distribution, lighting and heating equipment, etc., can solve the problems of high manual operation cost, heavy workload, high maintenance cost, etc., and achieve low manual operation cost and long service life Long-term, low-maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now the present invention is further described in conjunction with description of drawings and embodiments:

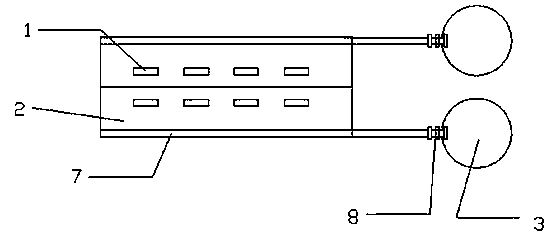

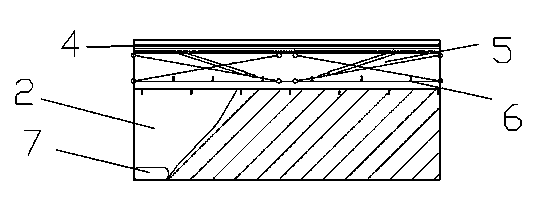

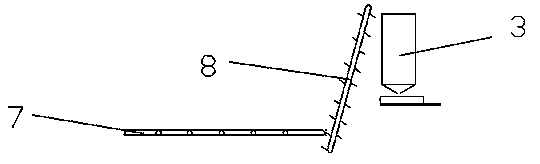

[0019] refer to figure 1 , figure 2 and image 3 , a large-scale automatic ice storage conveying system and conveying method, including an ice maker 1, a storage warehouse 2, a mobile ice rake device, a conveying device, and a temporary storage hopper 3, wherein: the ice maker 1 is provided with several sets of On the storage warehouse 2, the transfer device is connected to the storage warehouse 2 and the temporary storage hopper 3; the mobile ice rake device includes a driving mechanism 4 that moves back and forth, a lifting mechanism 5 that pushes up and down, and a sprocket structure. The ice rake 6, the driving mechanism 4 is installed on the driving beam track of the storage warehouse 2, the lifting mechanism 5 is placed under the driving mechanism 4 to hang the ice rake 6, and the lifting mechanism 5 is used to realize the ice rake 6. A hydraulic conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com