Automatic cleaning system for steam turbine power generation small unit condenser

An automatic cleaning and condenser technology, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of ineffective hard scale, achieve low fluid resistance, ensure high vacuum operation, and enhance high convective heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

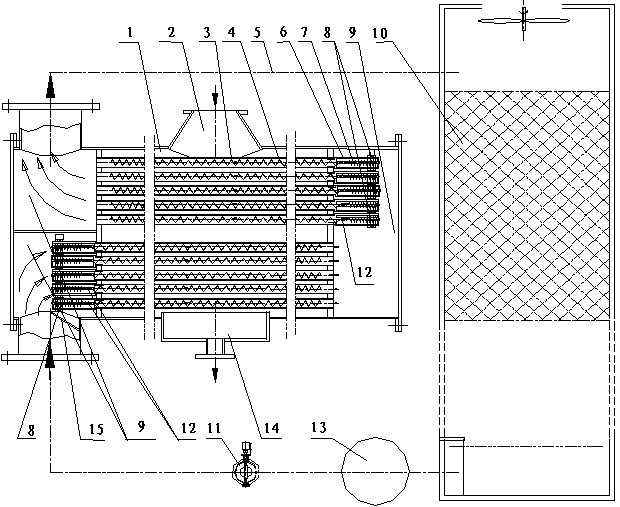

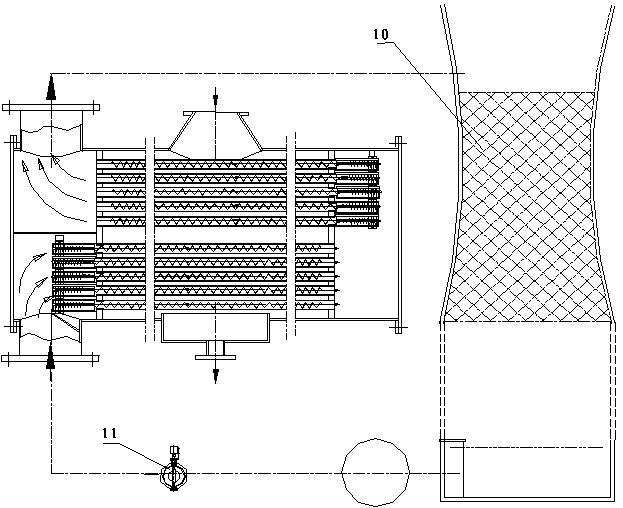

[0015] Attached below figure 1 , figure 2 , image 3 , Figure 4 The present invention is described in further detail. An automatic cleaning system for the condenser of a small steam turbine generator unit, the main components are wave flow machine 11, condenser pipe 3, cleaning screw 4, vibration-inducing spring 7, nozzle fixing frame 6, pipe box 9, circulation pump 13, circulation pipeline 5 .

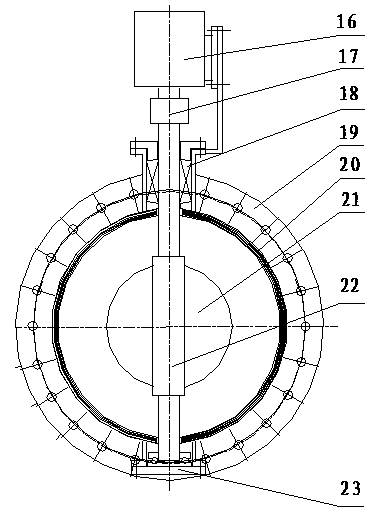

[0016] The wave flow machine 11 mainly consists of a wave flow plate 21, a rotating shaft 22, a slow motor 15 integrated with a motor reducer, a body 20, a stuffing box 18, and a bearing box 23. The wave flow machine 11 is installed and connected to the inlet pipe or outlet pipe of the cooling water circulation pipeline 5 through the flange 19 of the body 20 , but for technical transformation, it is most convenient to be installed at the outlet end of the circulation pipeline 5 . There is a large annular flow channel between the outer diameter of the wave flow disc 21 and the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap