Impact testing machine

A technology of impact testing machine and bullet holder, which is applied in the direction of impact testing, testing of machine/structural components, measuring devices, etc., and can solve problems such as inability to launch irregularly shaped projectiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

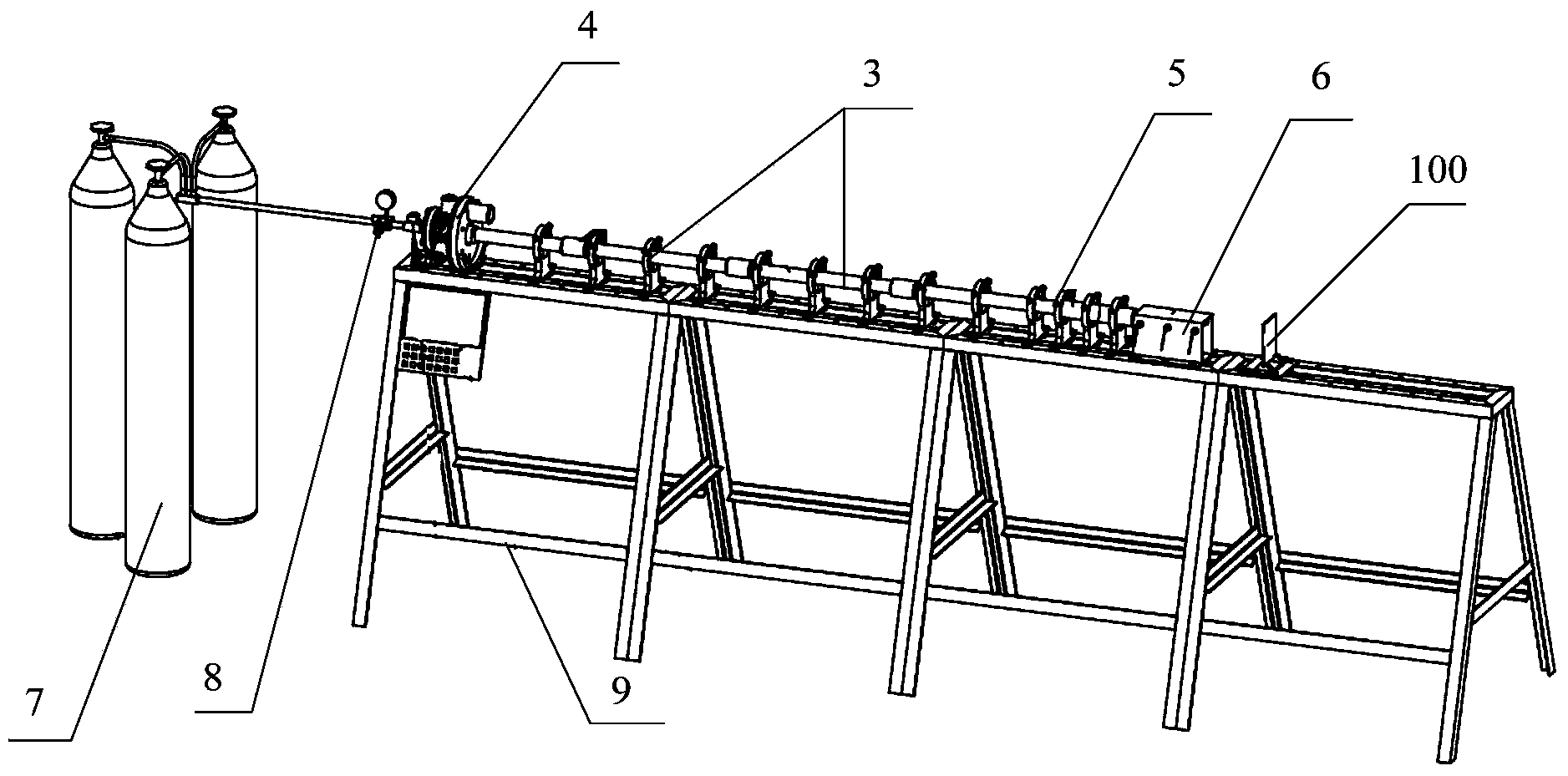

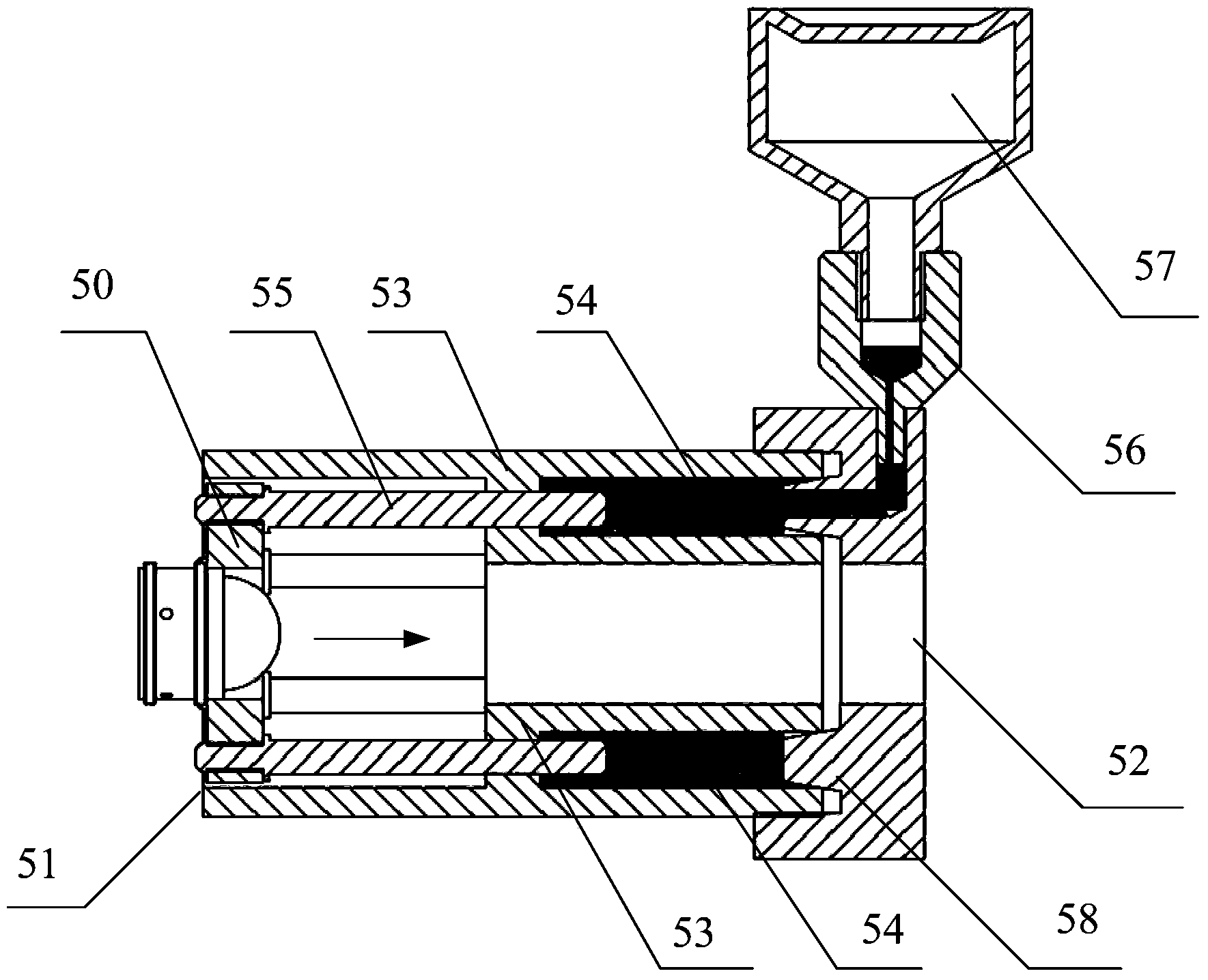

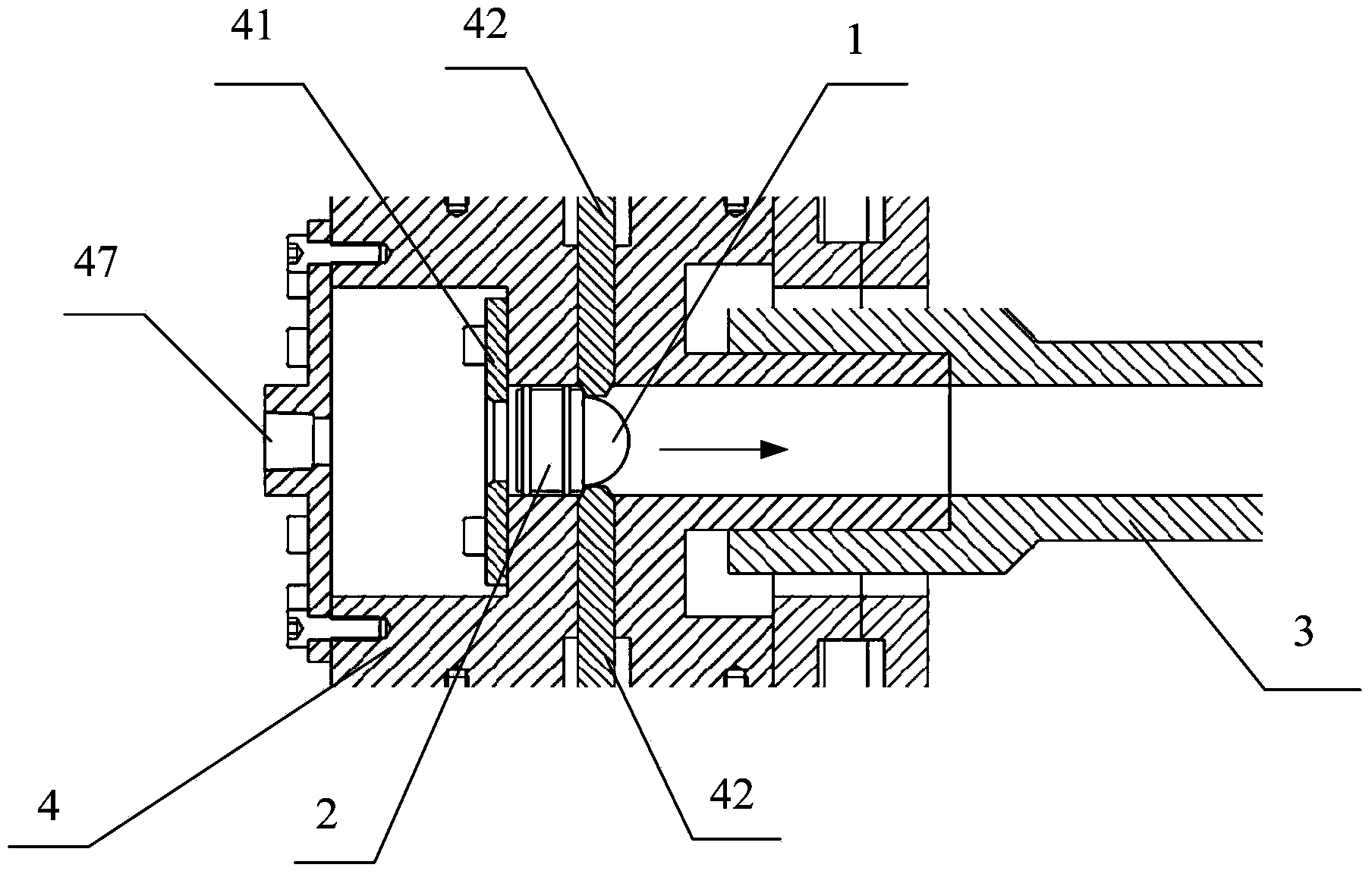

[0013] figure 1 It is a schematic structural diagram of the impact testing machine according to the embodiment of the present invention; Figure 4 It is a perspective view of the assembly of the impact testing machine according to the embodiment of the present invention. The impact testing machine of this embodiment includes: a sling 2, a gun barrel 3 and a sling recovery 5. The bullet holder 2 is a cylinder, and the bullet holder 2 in the embodiment of the present invention can be other revolving body structures with a shape similar to a cylinder, as long as the good air tightness between the bullet holder 2 and the gun barrel 3 can be ensured; the gun barrel 3 It is used to launch the sling 2, and the inner wall of the gun barrel 3 and the side of the sling 2 of the cylinder are in clearance fit to ensure that the sling 2 obtains good air tightness in the process of being accelerated. When the cartridge holder 2 is located in the gun barrel 2, the end of the cartridge hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com