Liquid crystal lens, manufacturing method of liquid crystal lens and display device

A technology of a liquid crystal lens and a manufacturing method, which can be applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven refractive index change, reducing the refractive effect of liquid crystal lens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

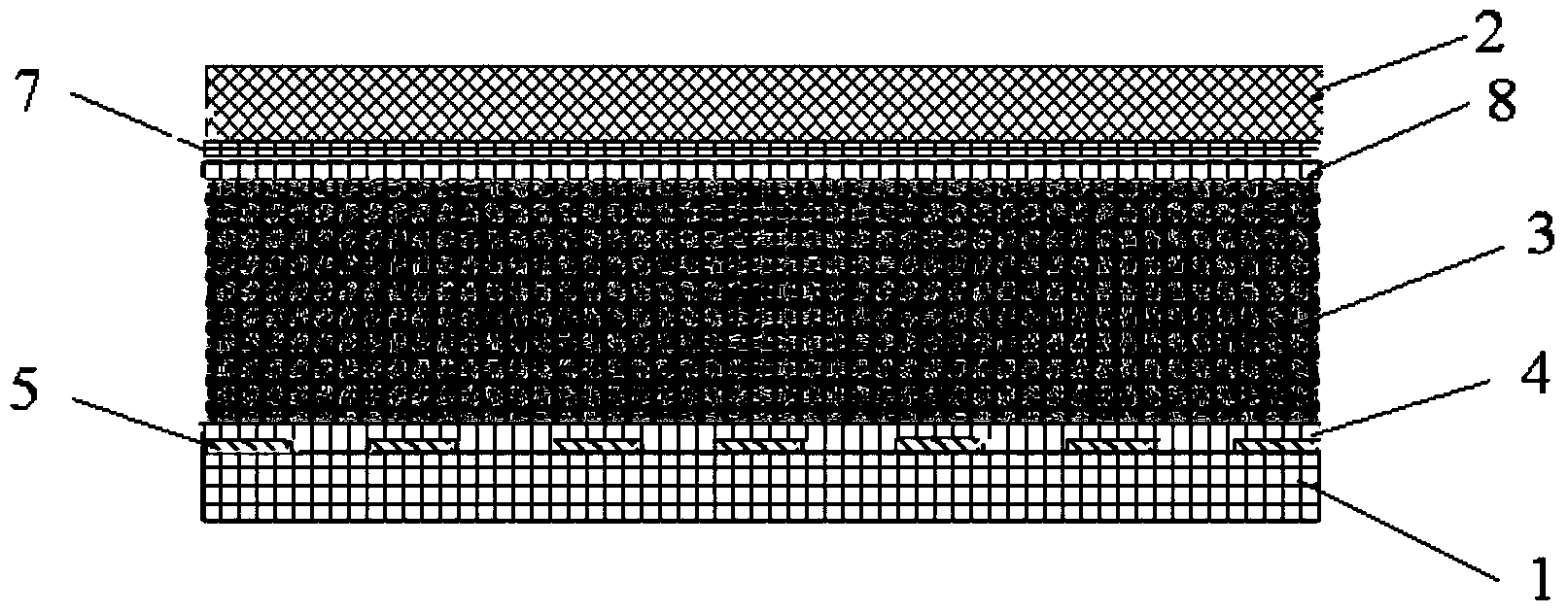

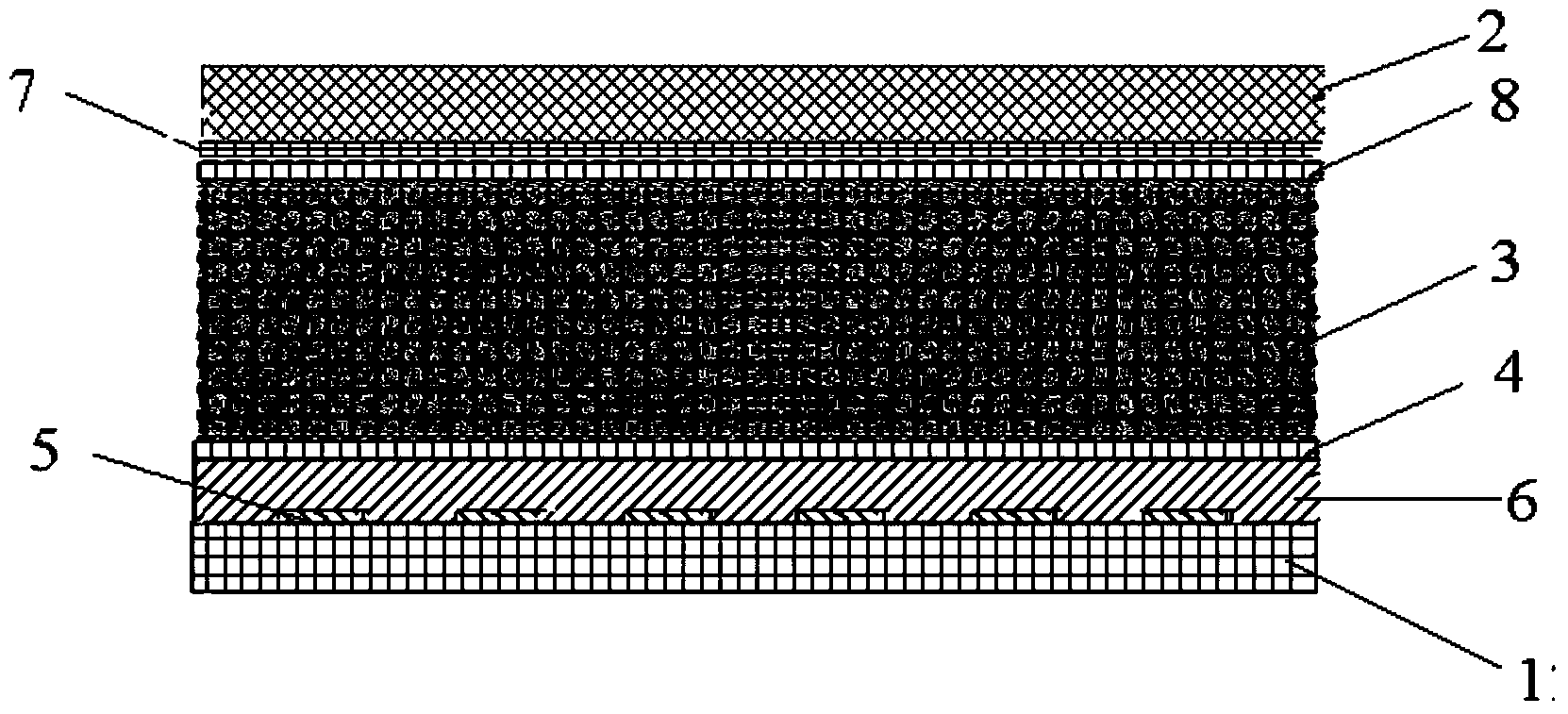

[0033] In order to solve the above-mentioned technical problems, an embodiment of the present invention provides a liquid crystal lens, such as image 3 Shown is a schematic structural diagram of a liquid crystal lens provided by an embodiment of the present invention. The liquid crystal lens includes: a first substrate 1, a second substrate 2, a liquid crystal layer 3 between the first substrate 1 and the second substrate 2, and a The first transparent electrode layer 5 and the first liquid crystal alignment layer 4 on the side close to the liquid crystal layer 3 on the first substrate 1 and between the first transparent electrode layer 5 and the first liquid crystal alignment layer 4 The flat layer 6. The second substrate 2 is provided with a second transparent electrode layer 7 near the side of the liquid crystal layer 3, the second transparent electrode layer 7 is a full-surface electrode, and a second transparent electrode layer 7 and the liquid crystal layer 3 are also p...

Embodiment 2

[0040]The embodiment of the present invention also provides a method for manufacturing a liquid crystal lens, such as Figure 5 Shown is a flow chart of a method for manufacturing a liquid crystal lens provided by an embodiment of the present invention, and the method includes:

[0041] 201: sequentially forming a pattern including a first transparent electrode layer, a flat layer, and a first liquid crystal alignment layer on the first substrate;

[0042] In the embodiment of the present invention, a patterning process is adopted to sequentially form patterns including a transparent electrode layer, a flat layer, and a first liquid crystal alignment layer on the first substrate; wherein, the patterning process includes patterning processes such as exposure, development, and etching, or printing and Composition techniques such as grid printing.

[0043] Wherein, the step of forming the planar layer includes: forming the planar layer by spin coating, deposition or printing.

...

Embodiment 3

[0050] An embodiment of the present invention also provides a display device, including the liquid crystal lens described in Embodiment 1 above. The display device includes but not limited to a three-dimensional display.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com