Permanent magnet linear motor control method

A permanent magnet linear motor and control method technology, applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., to achieve the effect of fast response speed, good stability, and optimized steady-state performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

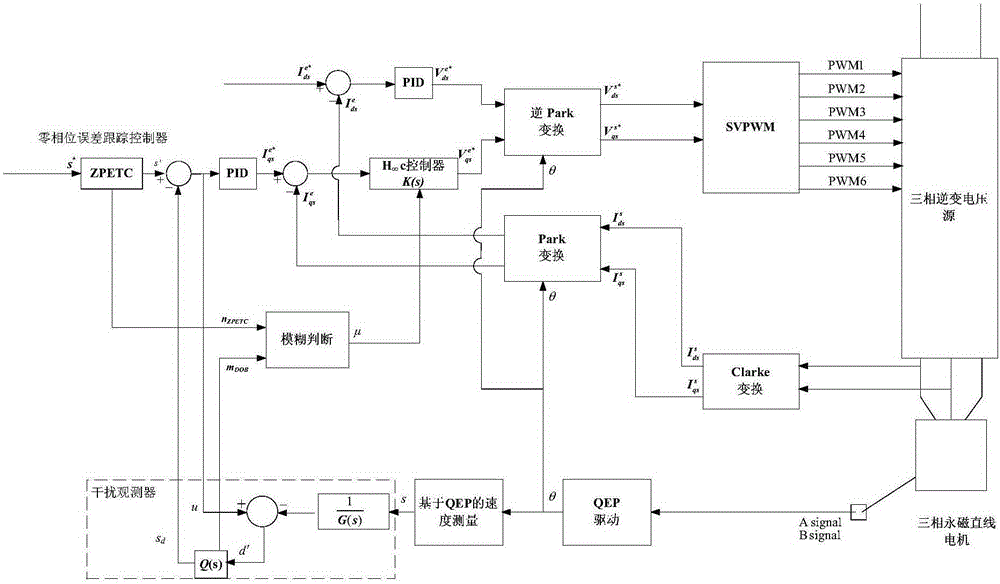

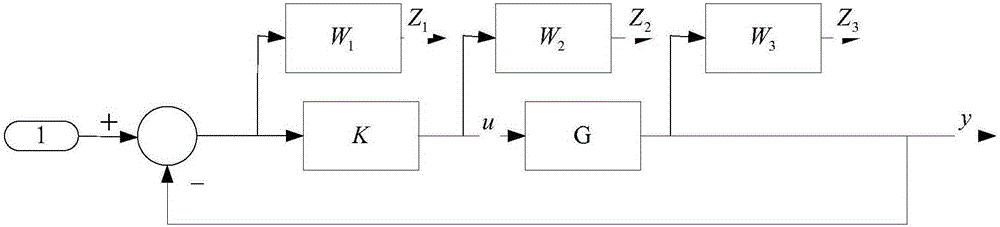

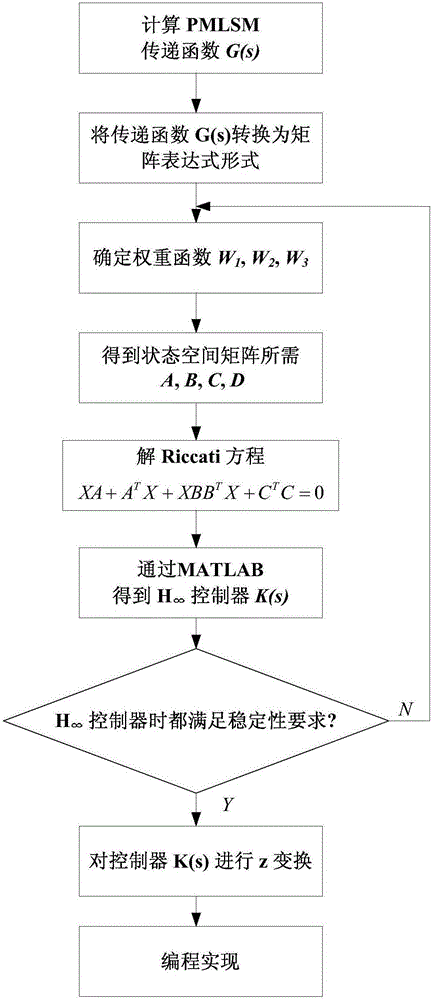

[0021] A permanent magnet linear motor control method, the feedback signal is detected through the current loop, the speed loop and the position loop, wherein the current loop adopts H ∞ Robust controller sets the output, the position loop uses the disturbance observer to process the feedback signal, and the zero-phase error tracking controller is used to process the given position signal; H ∞ The value of the parameter weight factor μ of the robust controller is obtained from the output of the zero-phase error tracking controller and the output in the denominator of the disturbance observer through fuzzy judgment. In this control method, according to the electromagnetic force, voltage balance and mechanical equation of the permanent magnet linear motor, the mathematical model PMLSM of the permanent magnet linear motor is obtained, and each controller is designed based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com