Narrow frame one-chip type capacitor inducting touch screen and manufacturing method thereof

A capacitive sensing, single-chip technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of declining yield rate and increasing production cost, and achieve the effect of narrow border requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

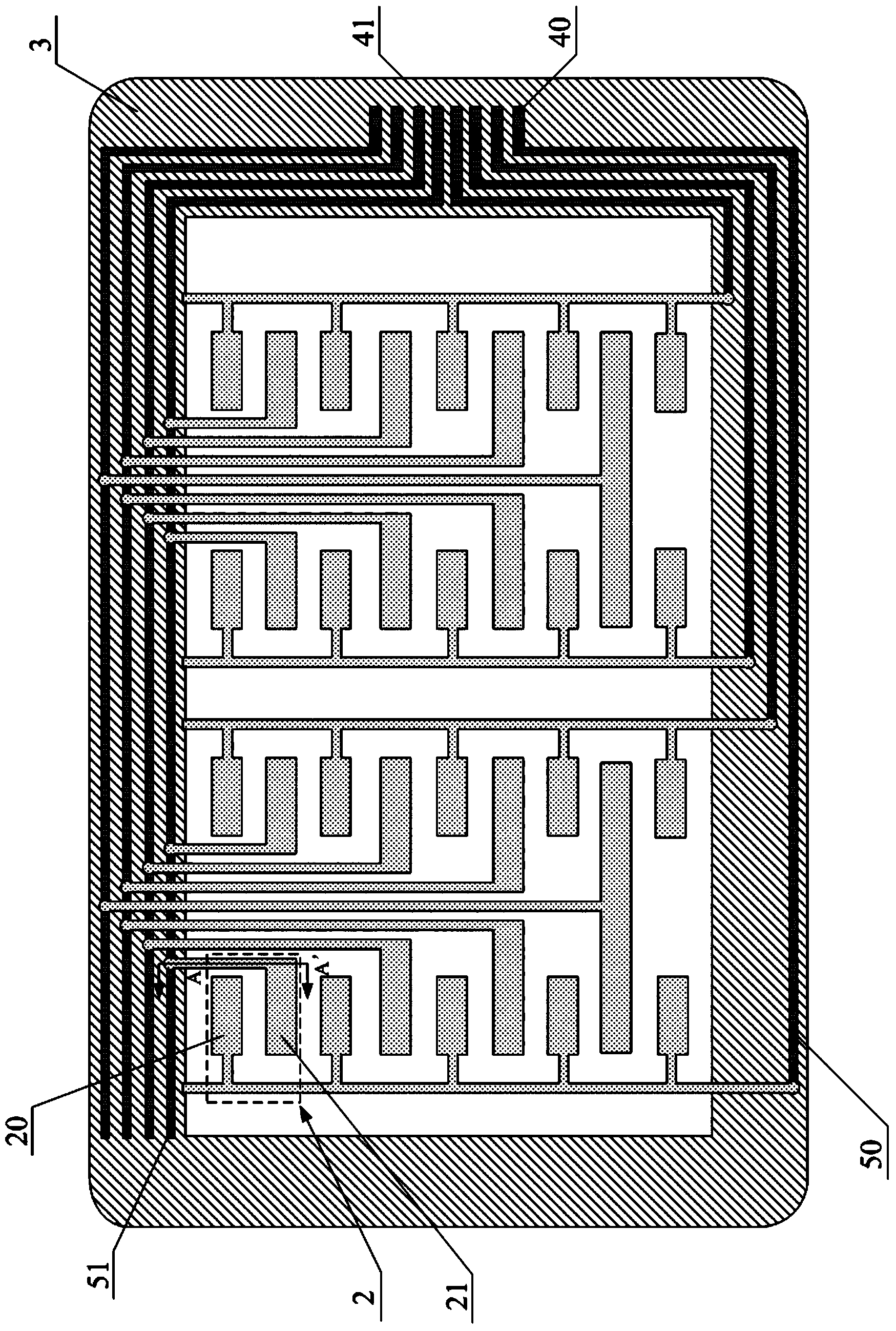

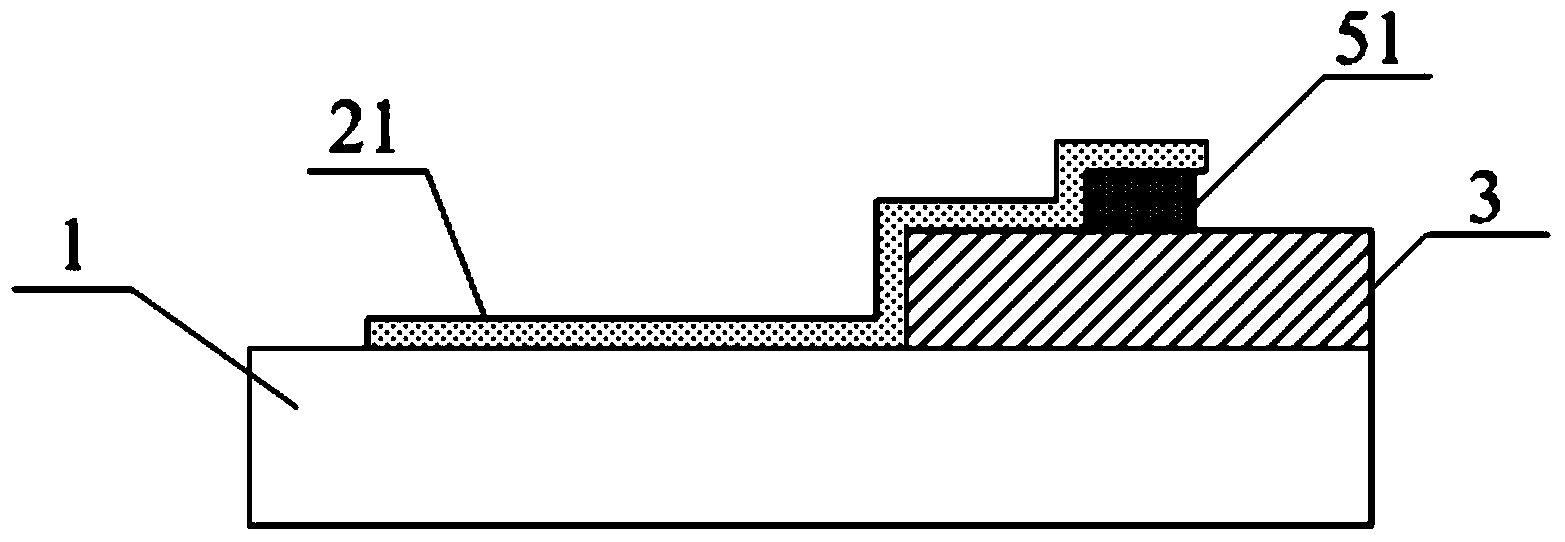

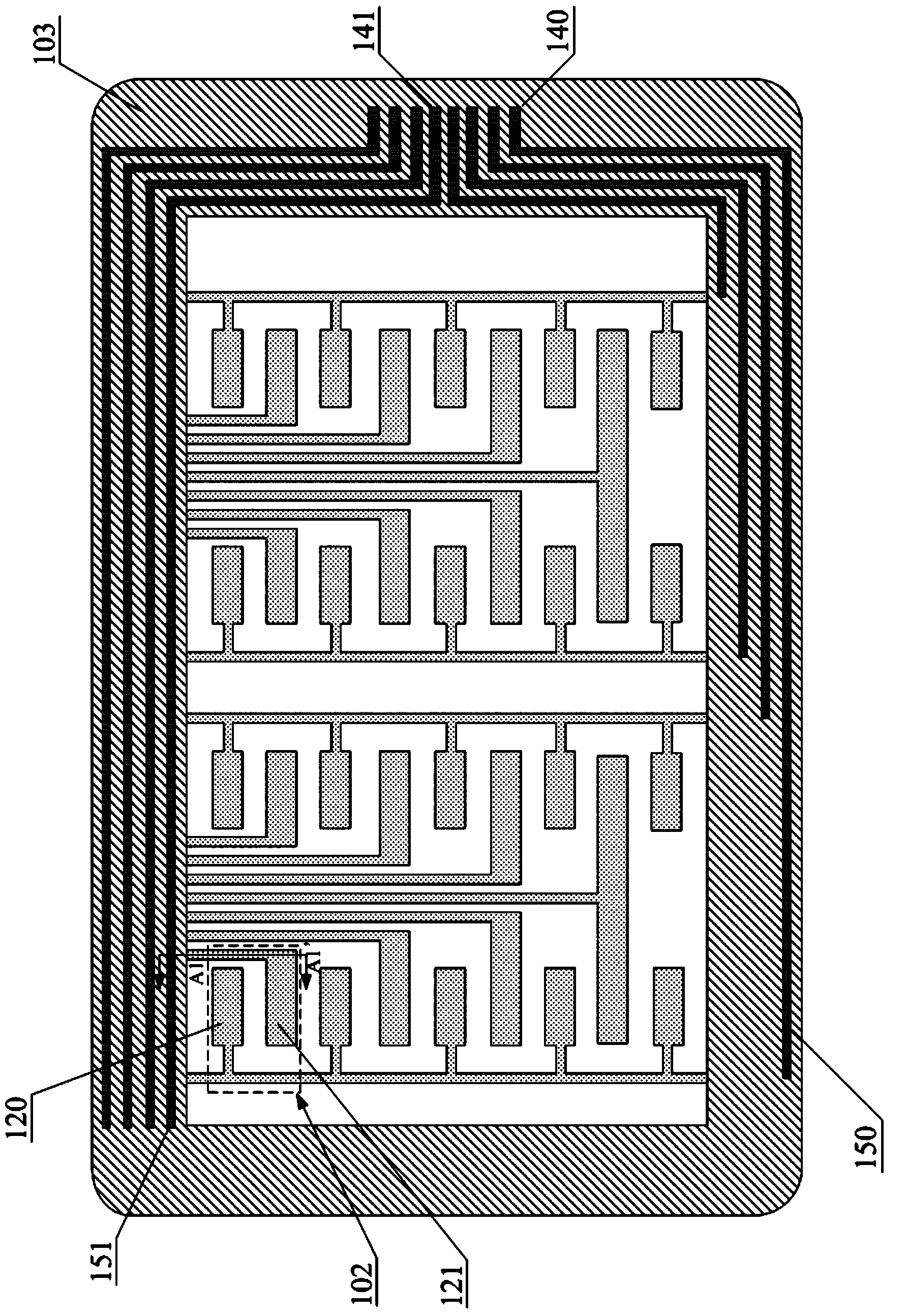

[0030] Such as image 3 and 4As shown, in a preferred embodiment, the capacitive touch screen of the present invention includes a substrate 101, a plurality of touch units such as touch unit 102, a color layer 103, a plurality of electrodes such as electrodes 140 and 141, such as electrode lines A plurality of electrode traces of the wires 150 and 151 , the traces of the touch unit, and the conductor 161 . Wherein, the color layer 103 is insulated, and is used to form a non-visible area of the capacitive touch screen, and has a through hole, such as the through hole 171; 120 and a sensing part 121; a plurality of touch units form an array of touch units, distributed on the first surface of the substrate 101 and in the operating area of the capacitive touch screen; on the substrate 101, a plurality of touch units are routed from each The driving part and sensing part of the touch unit extend to each through hole on the color layer 103, for example, the touch unit wiring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com