Electronic element installation system and electronic element installation method

A technology for electronic component installation and electronic components, applied in the direction of electrical components, electrical components, etc., can solve problems such as interference, insufficient joint strength, and inability to form solder joints, and achieve the effect of accurate height dimensions and sufficient joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

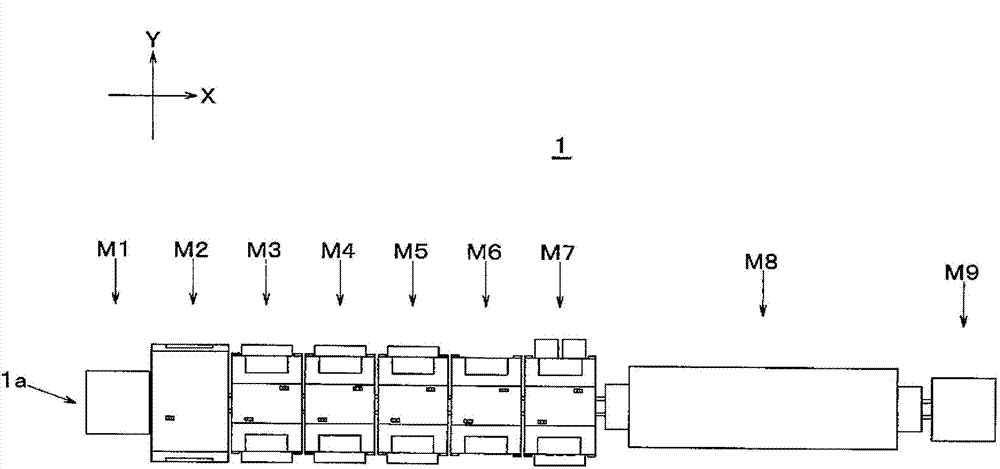

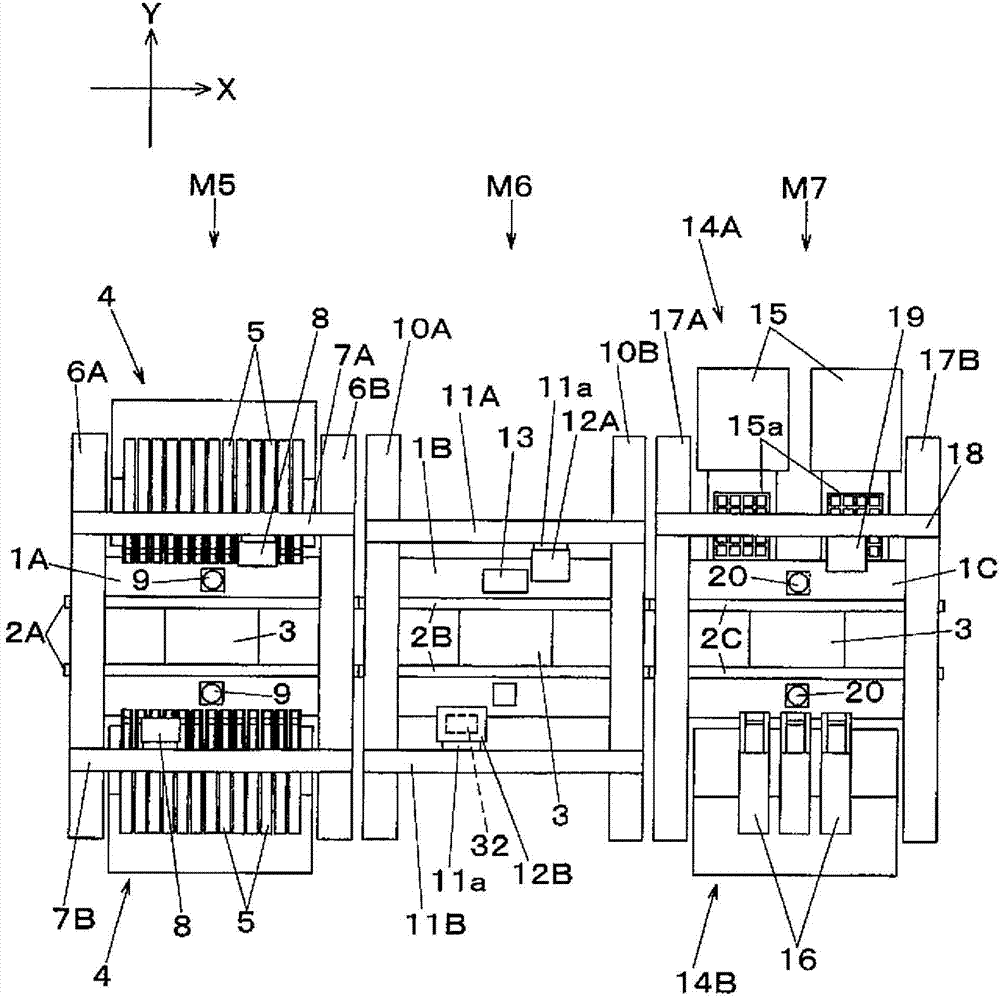

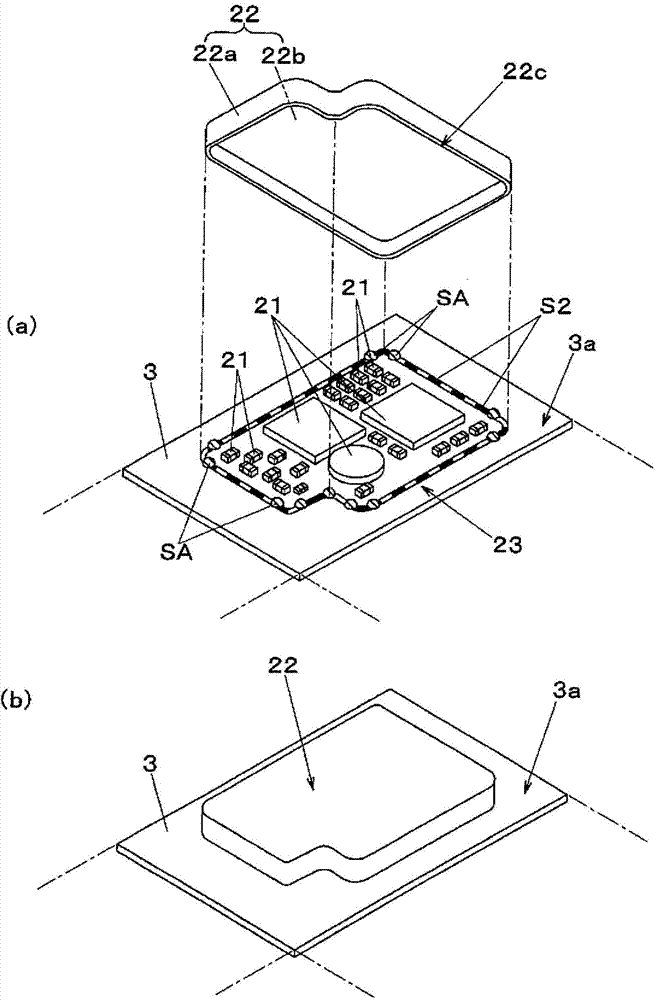

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 , figure 2 , the structure of the electronic component mounting system 1 will be described. exist figure 1 Among them, the electronic component mounting system 1 has the following function: using the electronic component mounting line 1a composed of a plurality of equipment (substrate supply device M1 to substrate recovery device M9) having a conveying member for conveying substrates, electronic components and substrates for covering A shield element of the electronic component mounted on the substrate is mounted on the substrate. in addition, figure 2 The detailed structure of the 1st electronic component mounting apparatus M5, the solder coating apparatus M6, and the 2nd electronic component mounting apparatus M7 is shown.

[0039] The electronic component mounting production line 1a connects the substrate supply device M1, the solder pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com