Method for producing bread from aerated dough

A dough and bread technology, applied in the direction of dough processing, dough preparation, mixing/kneading with additional aeration equipment, etc., can solve the problems of reducing the quality of aerated dough, increasing energy requirements, reducing production efficiency, etc., to achieve aeration The effect of reducing time, improving precision, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

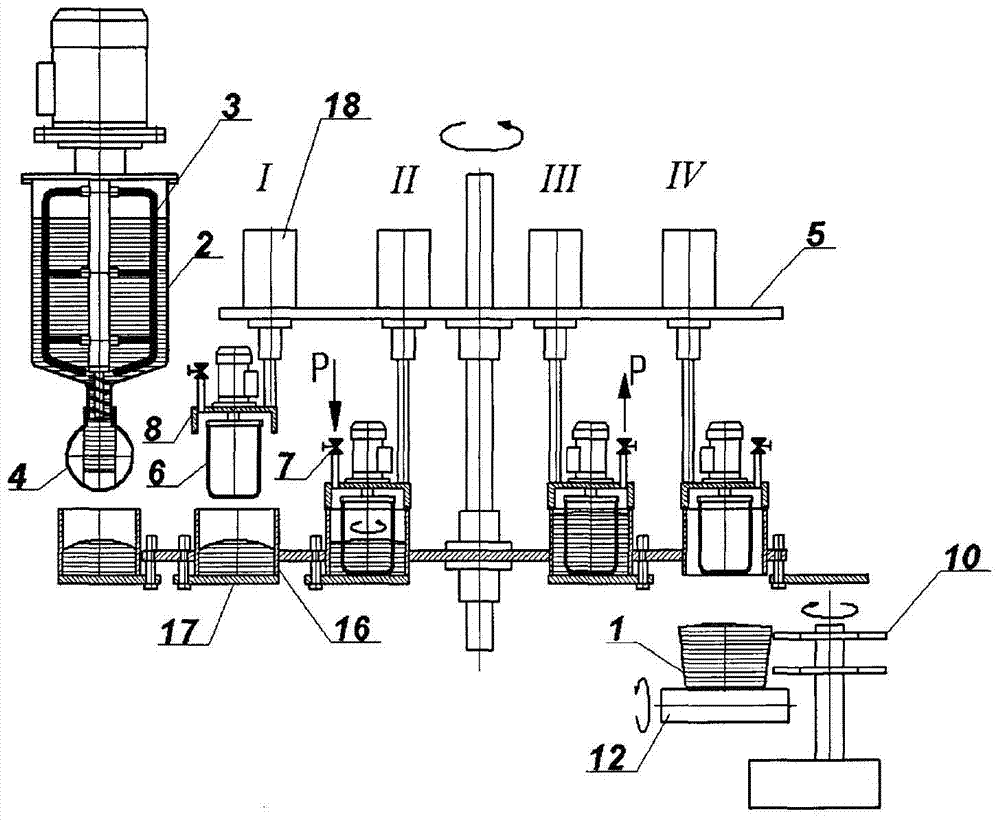

[0026] The method of producing bread using aerated dough is realized by the following equipment.

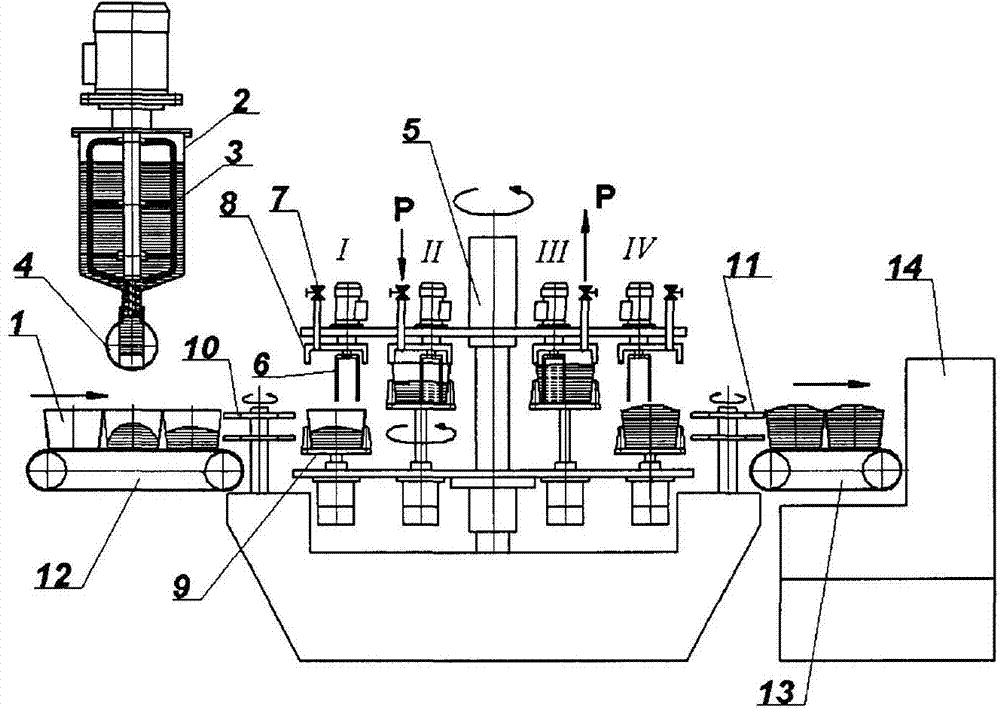

[0027] figure 1 A production line for aerated and unleavened bread is shown, the aeration of the dough takes place directly in the baking mold 1, comprising: a dough mixing device 2 with a mixing device 3, equipped with a dough divider 4; Machine 5 with several positions for aerating the dough, each of which is provided with an aerating device 6 , a device 7 for supplying and adjusting pressure, a sealing cover 8 and a lifting table 9 . The production line comprises input and output starwheels 10 , 11 , supply and output conveyors 12 , 13 and ovens 14 . The rotation speed of the aeration rotary machine and the number of aeration positions are determined by the production volume of the production line and the aeration time of the dough. Roman notations I-IV indicate the stages of the process.

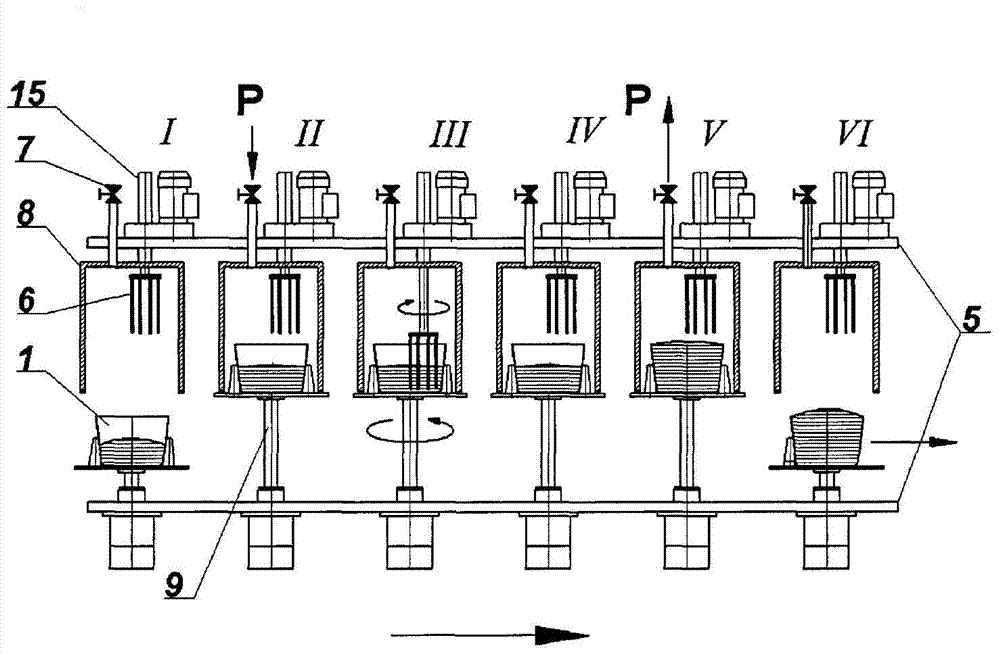

[0028] figure 2 Shown are six stages of the inflation process on an inflation spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com