Device for detecting and evaluating product-specific information of products of food-processing industry, system comprising such device, and method for processing products of food-processing industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

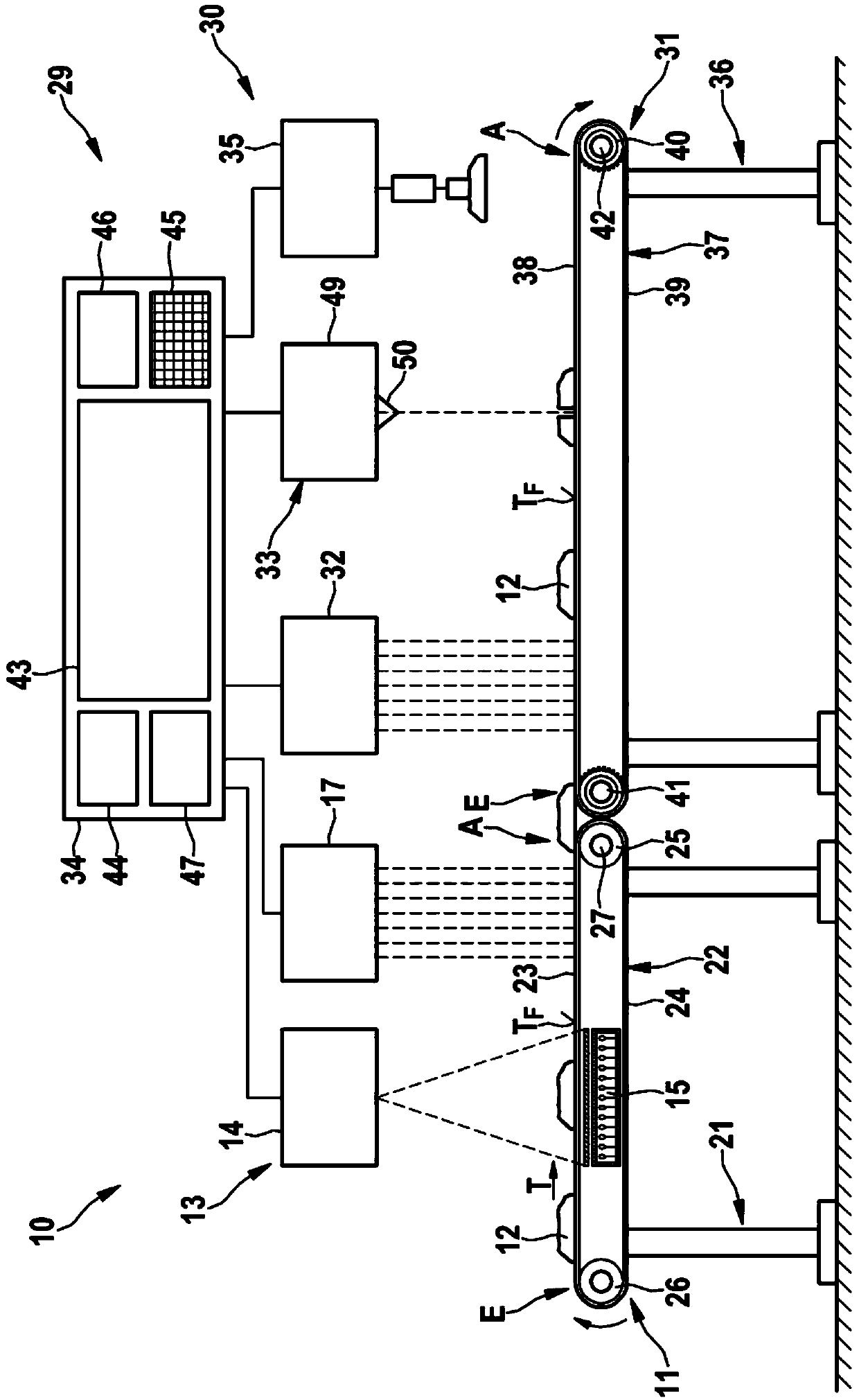

[0040]The device shown in the figure is configured to acquire and analyze product-specific data for fish fillets. Thus, the system shown is configured to process, ie fillet, fish. However, in the same way, the device and system are configured to acquire and analyze product-specific data and process other products of the food processing industry, such as meat, poultry.

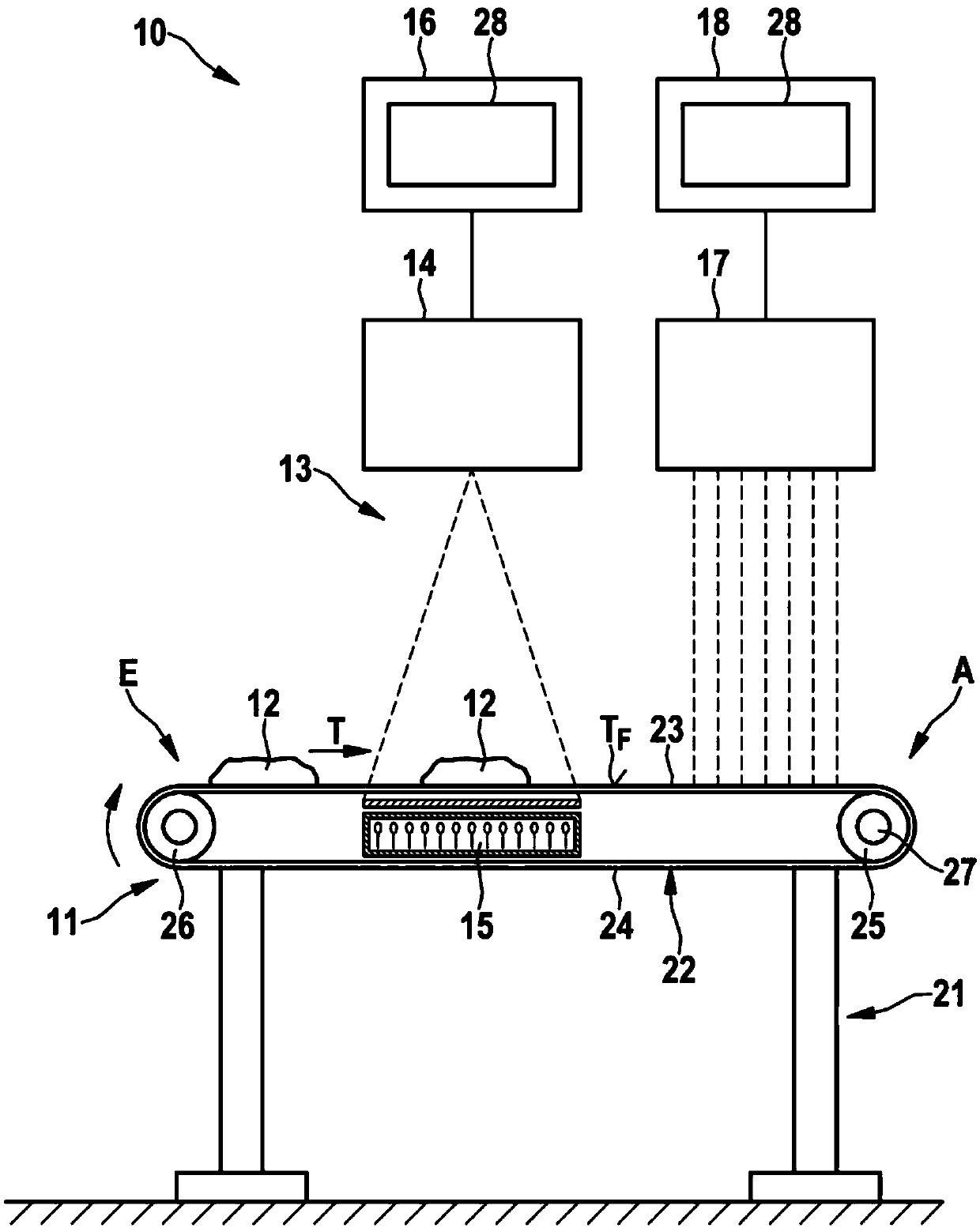

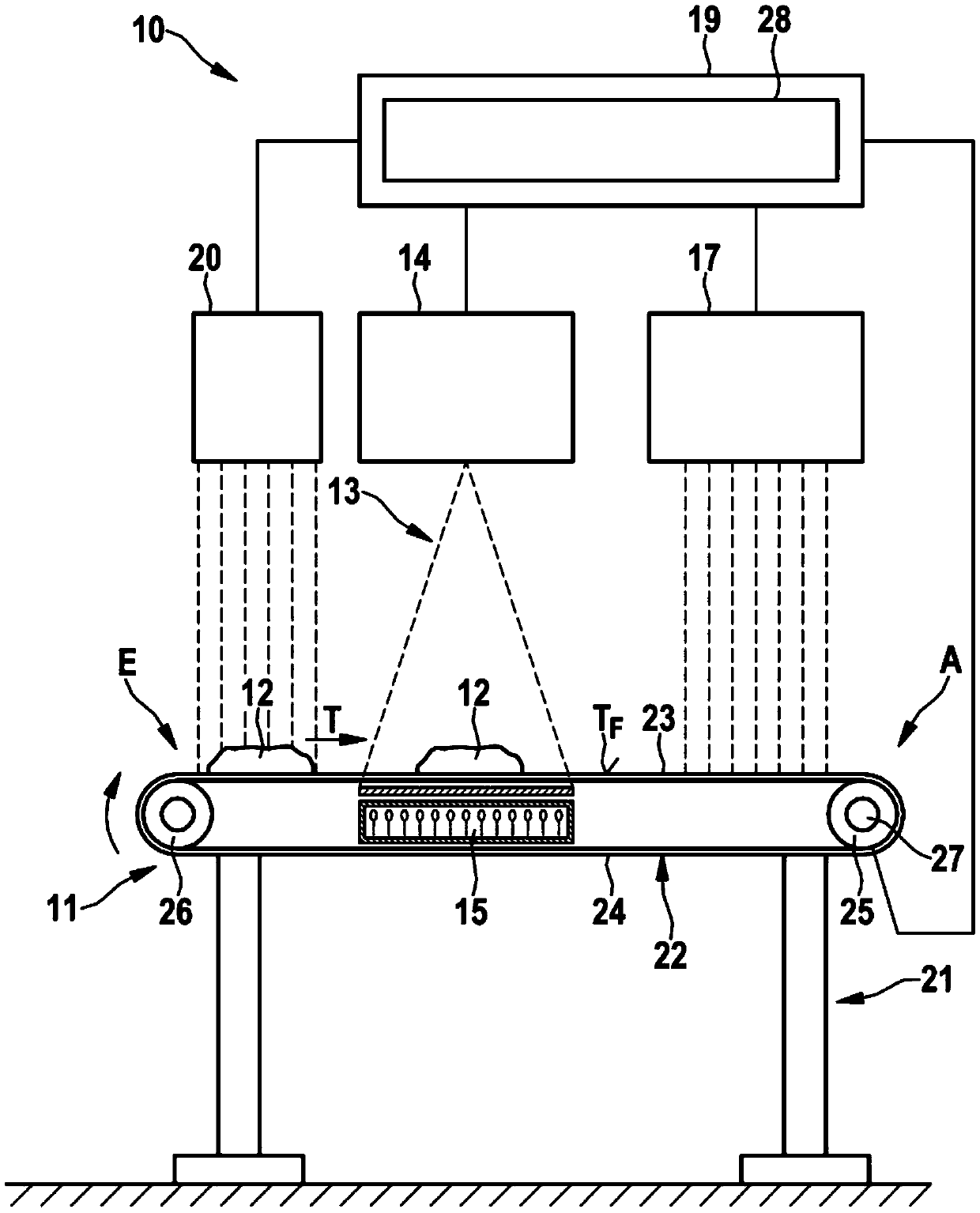

[0041] figure 1 Shown is an apparatus 10 designed and constructed to acquire and analyze product-specific data and comprising a conveyor 11 without gaps in the conveying plane for transporting separated products 12 in a conveying direction T from The entry end E conveys to the exit end A; an X-ray unit 13 with at least one X-ray source 14 and at least one X-ray camera 15 or at least one X-ray detector for acquiring product-specific data, wherein the X-ray source map 14 and the X-ray camera 15 are assigned to the conveyor 11 in such a way that a product 12 can be guided between the X-ray source 14 and the X-ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com